Rectangular patterned Si substrate AlN template for GaN semiconductor material epitaxy and preparation method of rectangular patterned Si substrate AlN template

A semiconductor and patterning technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, chemical instruments and methods, etc., can solve problems such as cracks in GaN thin films, achieve low cost, high product quality, and improve crystal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

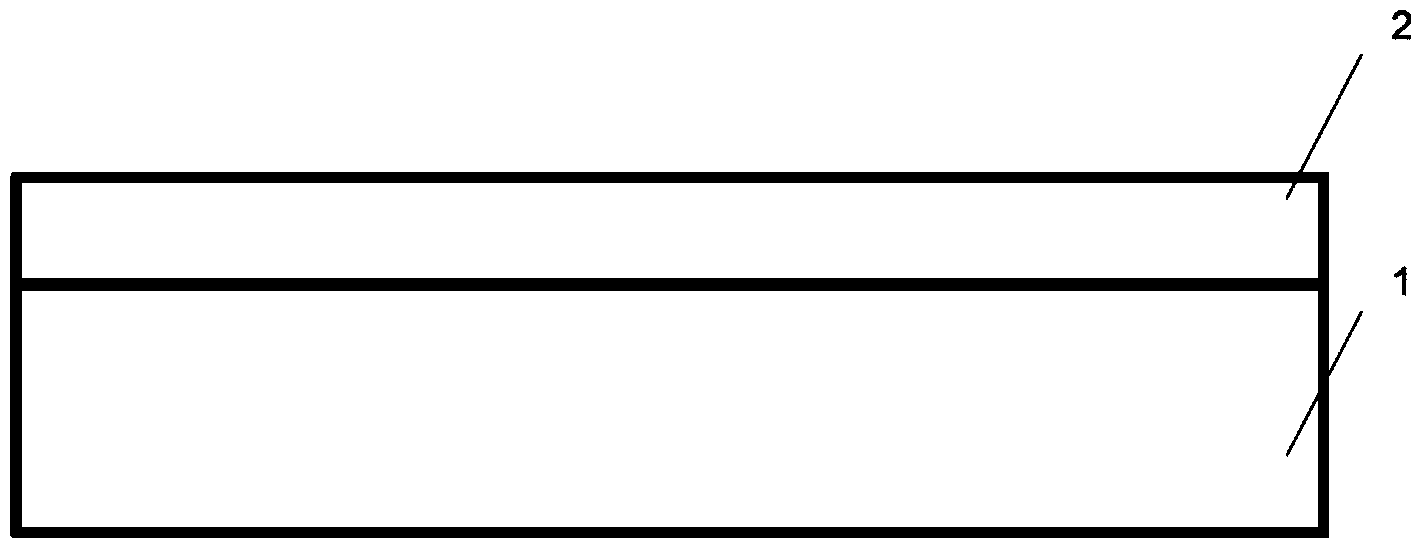

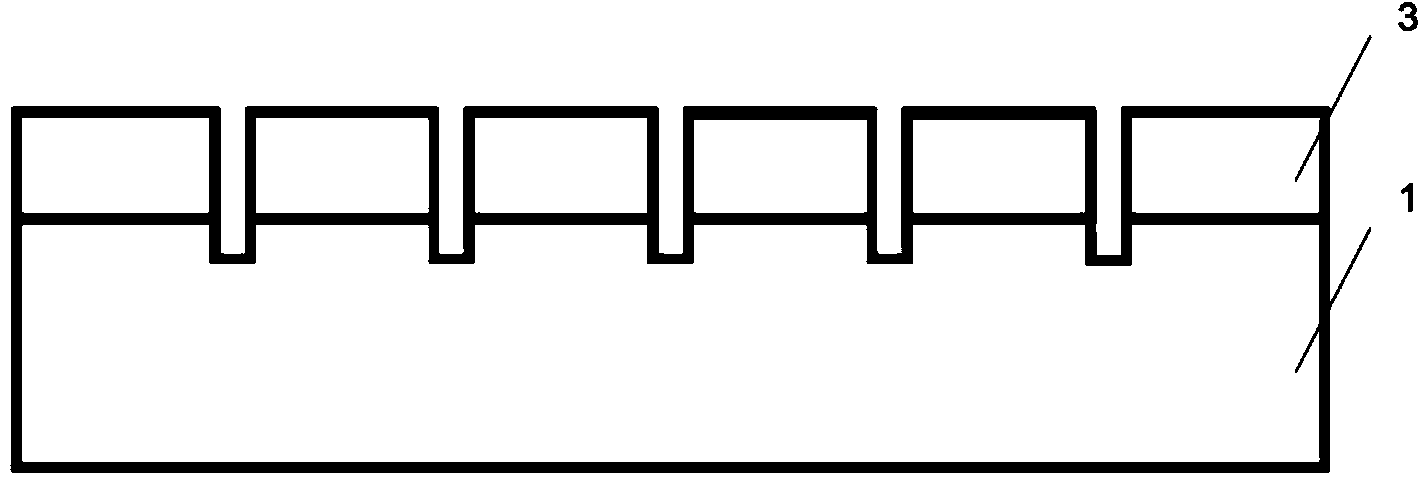

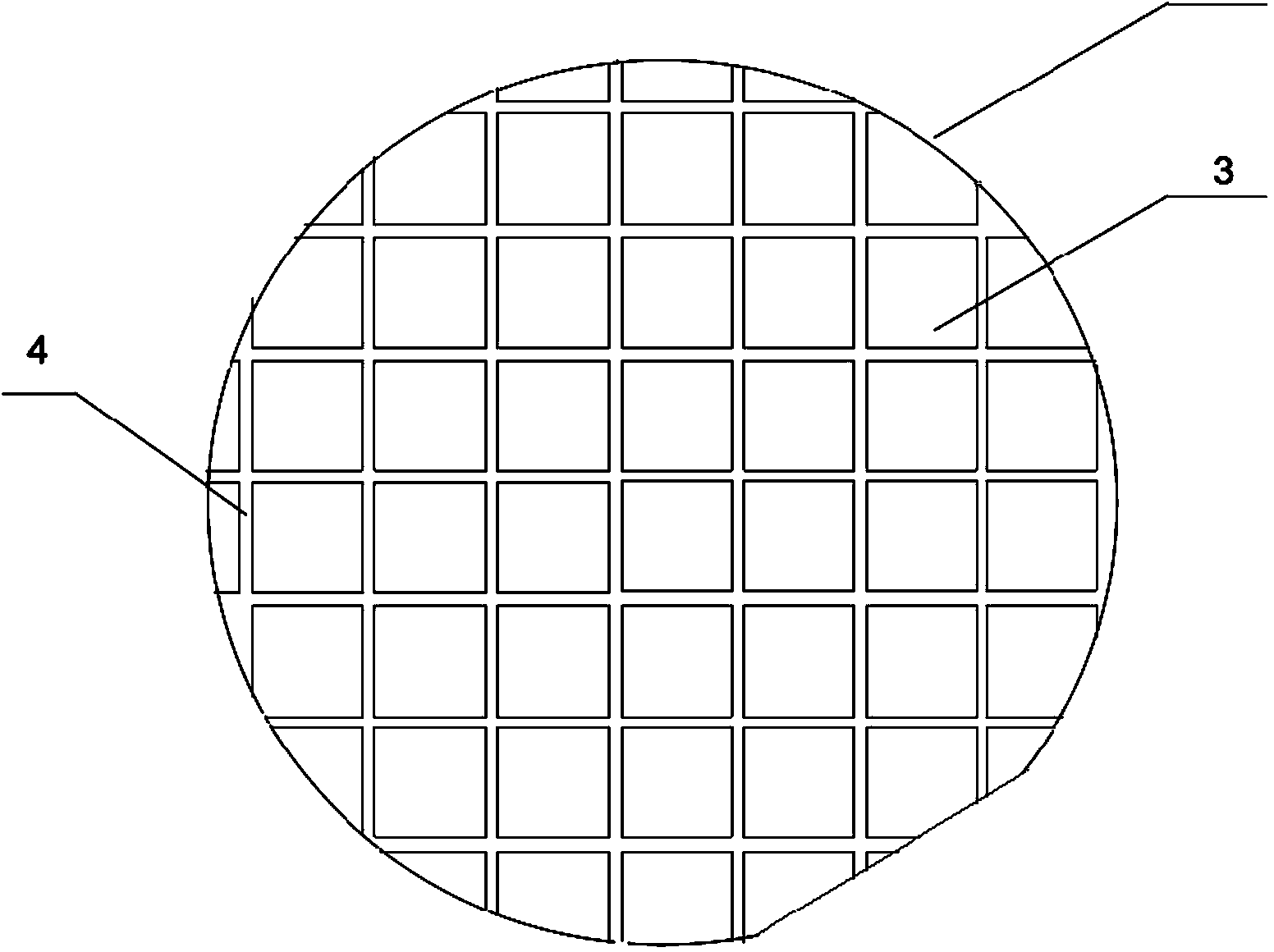

[0030] Attached figure 1 -, 3, a rectangular patterned Si substrate AlN template for epitaxy of GaN semiconductor materials, which includes a Si substrate 1 and a (111) crystal plane on the Si substrate 1 as an AlN template layer for crystal orientation epitaxial growth 2. A plurality of strip-shaped trenches 4 perpendicular to each other are etched on the AlN template layer 1 to form a plurality of mutually independent rectangular platforms 3. The thickness of the AlN template 2 layer is 50nm; the size of the rectangular platform 3 is 1mm×1mm, the width of the strip groove 4 is 10μm and the depth is 8μm

[0031] It is prepared by the following method, including the following steps in sequence:

[0032] a. Clean the Si substrate.

[0033] b. Using the (111) crystal plane of the Si substrate as the crystal orientation, an AlN template layer is grown on the Si substrate by pulsed laser deposition process: the pulsed laser deposition process taste: the substrate temperature is 650℃, an...

Embodiment 2

[0036] This embodiment is modified on the basis of Embodiment 1, and the difference is that the size of the rectangular platform of the rectangular AlN template layer used is 0.5 μm×0.5 μm.

Embodiment 3

[0038] Attached Figure 4-6 Using the rectangular patterned Si substrate AlN template for epitaxy of GaN semiconductor materials of Example 1, a GaN film grown on the Si substrate is prepared, which includes Si substrate 1, AlN template layer 2, and from bottom to top. Intermediate layer 5 and GaN epitaxial layer 6, in which the intermediate layer is Al from bottom to top x Ga 1-x N buffer layer, AlN / GaN insertion layer, SiN x Insertion layer, GaN nucleation layer. Including it is prepared by the following method: the rectangular patterned Si substrate AlN template for epitaxy of GaN semiconductor material prepared in Example 1 is placed in a metal organic chemical vapor deposition reaction chamber, and Al is epitaxially grown in sequence. x Ga 1-x N buffer layer, AlN / GaN insertion layer, SiN x Insertion layer, GaN nucleation layer and GaN epitaxial layer, where Al x Ga 1-x N buffer layer, AlN / GaN insertion layer, SiN x The insertion layer and the GaN nucleation layer constitute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com