Prefabricated underground diaphragm wall and method for constructing outer basement wall and floor slabs

An underground diaphragm wall and prefabricated technology, applied in excavation, artificial island, sheet pile wall, etc., can solve problems such as cumbersome process, unrealizable longitudinal connection, and structural damage of underground diaphragm wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

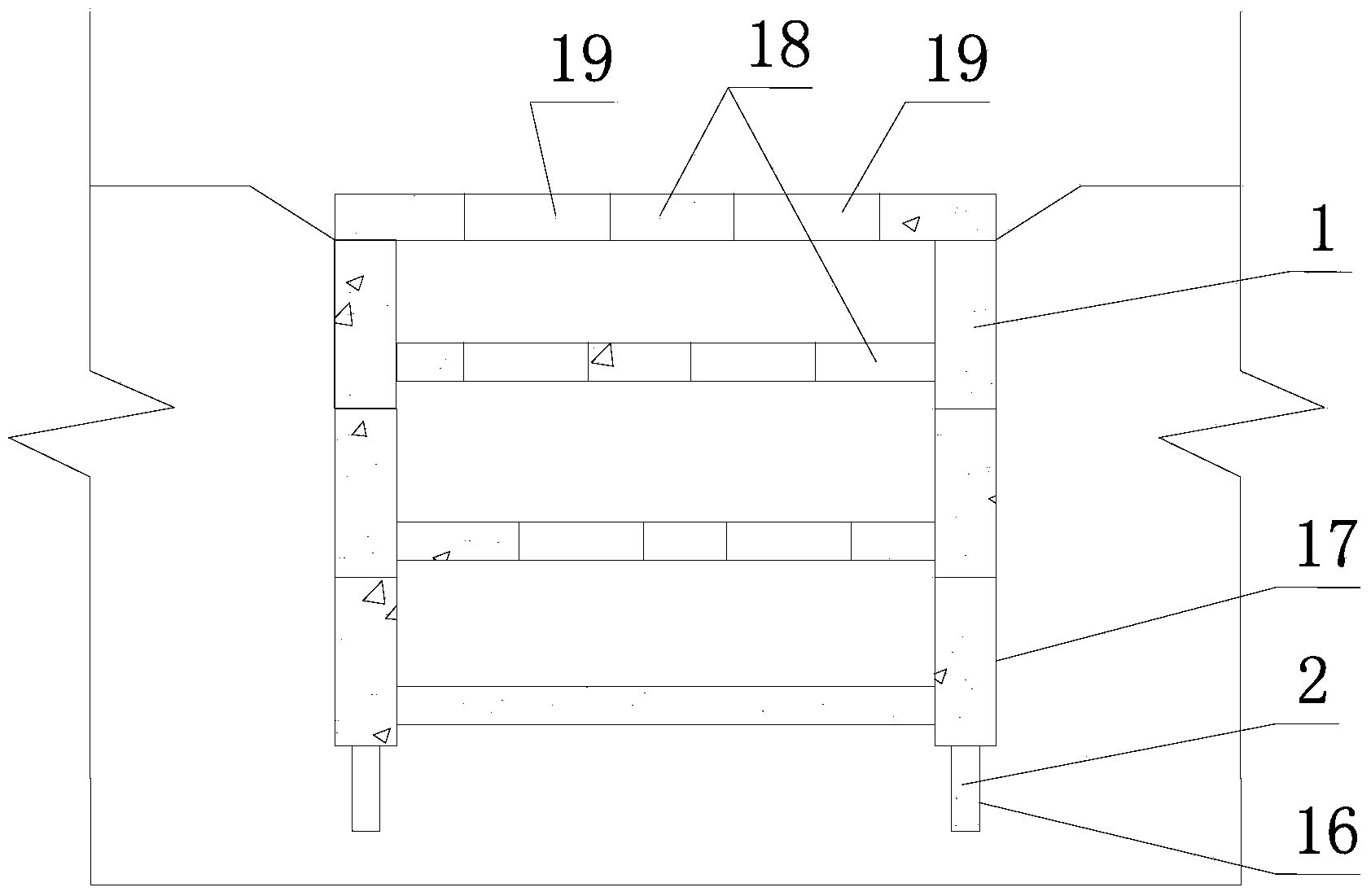

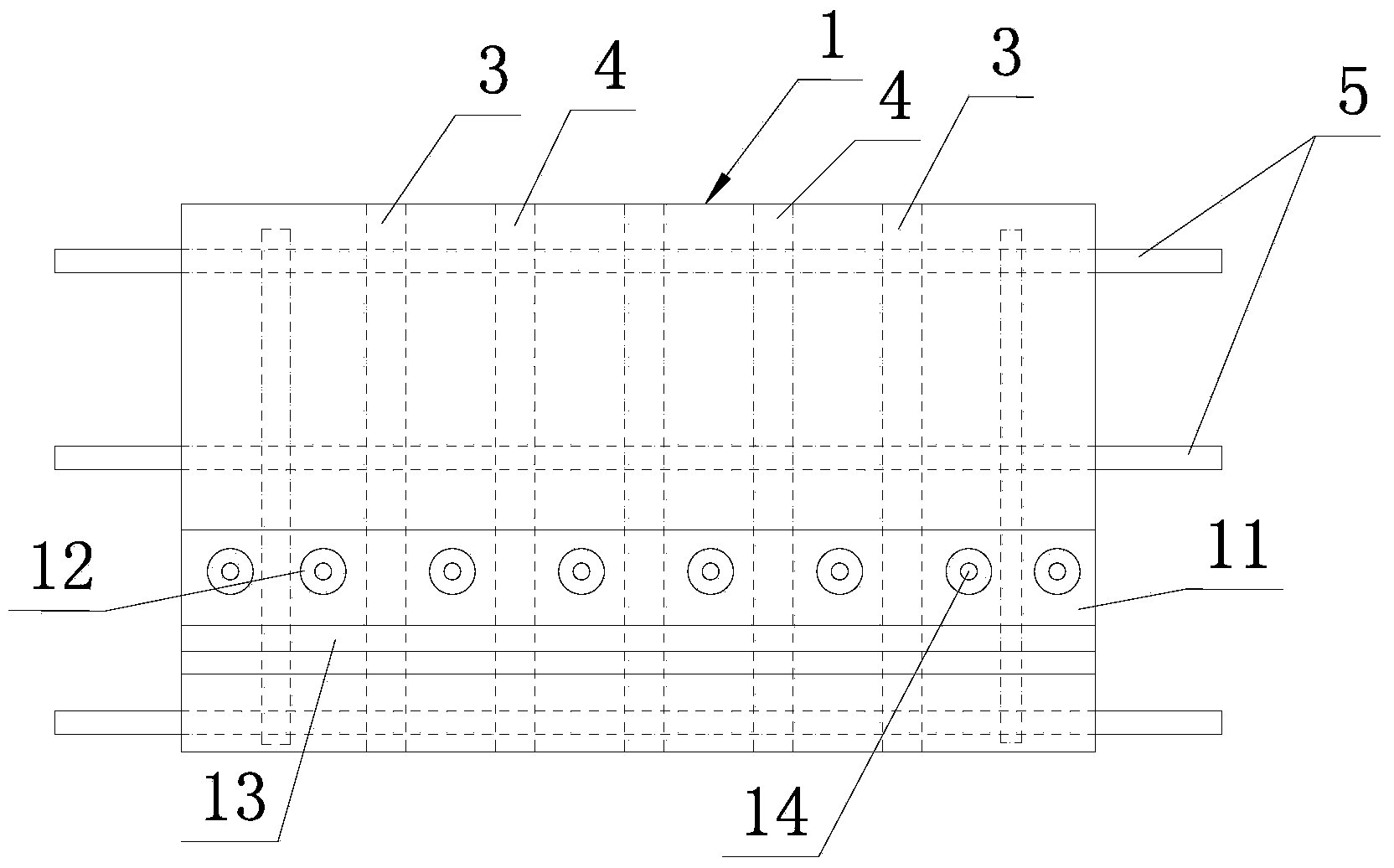

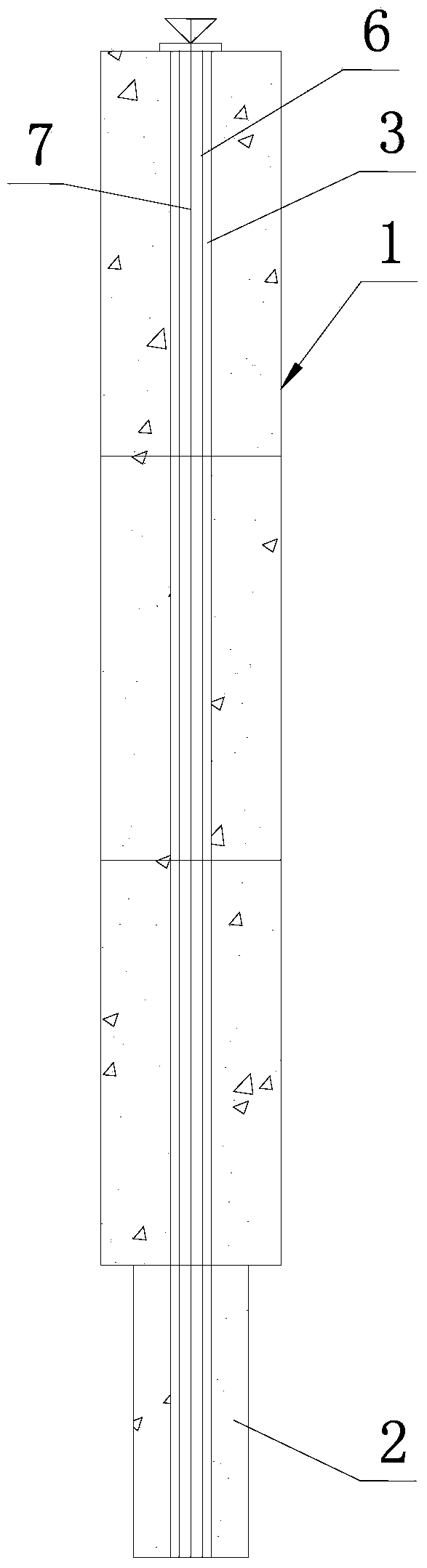

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the prefabricated underground continuous wall of the present invention includes a plurality of wall monomers 1 and a plurality of pile foundations 2 . Each wall unit 1 runs through a plurality of prestressed holes 3 and a plurality of non-prestressed holes 4 in the longitudinal direction, and the transverse reinforcement 5 of each wall unit 1 protrudes from the left and right sides of the wall unit 1 . A plurality of wall monomers 1 are stacked vertically to form a wall row, and a prestressed steel bar 7 with a sleeve 6 runs through the prestressed hole 3 of all the wall monomers 1 in each wall row, and the lower end of the prestressed steel bar 7 and the sleeve The lower ends of the pipes 6 are all anchored in the concrete of the pile foundation 2, the prestr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com