Pressure testing device and method for cleaning pipeline

A pressure testing and pipeline technology, applied in the field of pipeline pigging pressure testing devices, can solve problems such as hidden safety hazards, low construction efficiency, large workload, etc., and achieve the effects of flexible and convenient construction, improved work efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

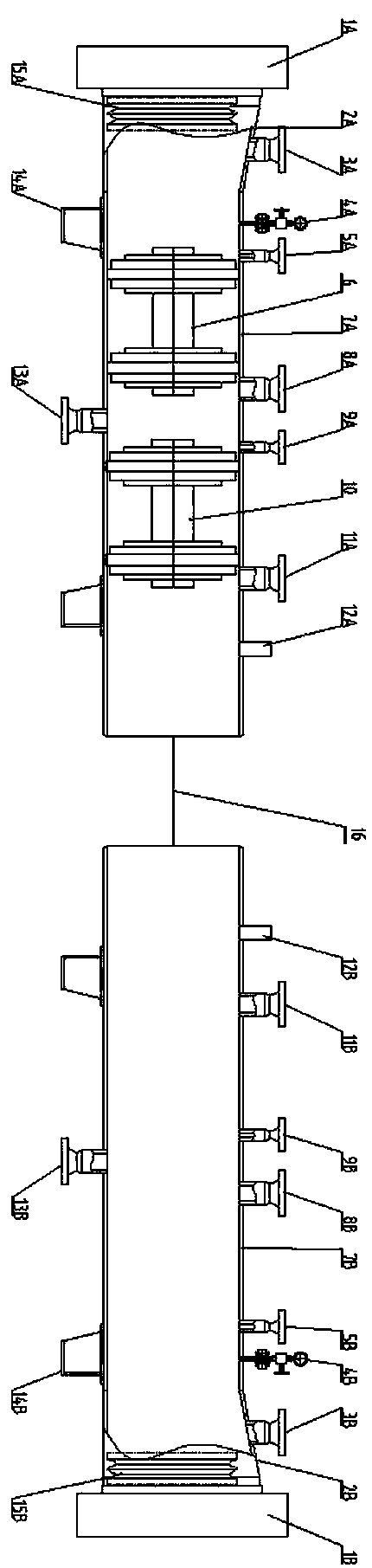

[0073] The pipeline pigging pressure test device of this embodiment includes two pressure test heads, which are connected to the two ends of the pipeline 16 respectively. It is connected to the pipeline, and the other end is a reduced-diameter structure equipped with blind plates 1A, 1B and anti-collision airbags 15A, 15B; two pigs are arranged in the cylinder, which are called the first pig 6 and the second pig respectively. The pig 10, at this time, the opening and outlet on the upper part of the cylinder should ensure that the water or compressed air in the pipeline and between the pigs can be discharged to prevent air dead ends.

[0074] Therefore, at this time, the upper part of the cylinder is provided with first inlets 3A, 3B, second inlets 8A, 8B, first outlets 5A, 5B and second outlets 9A, 9B; the first inlet 3A is located between the blind plate 1A and the first clearing On the cylinder between the pipe cleaners 6, the first outlet 5A is located on the cylinder betwe...

Embodiment 2

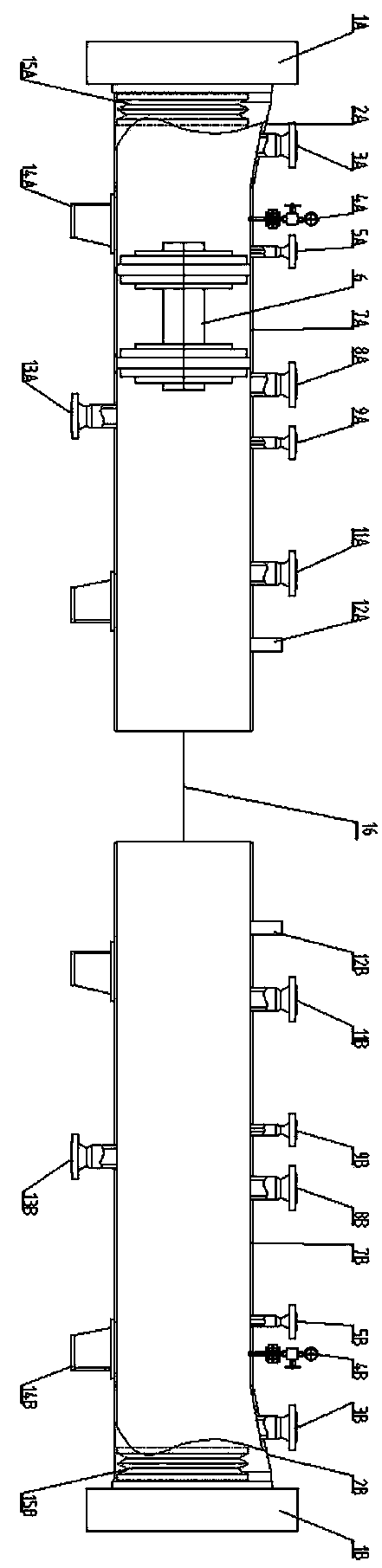

[0104] The pipeline pigging pressure test device of this embodiment includes two pressure test heads, which are connected to the two ends of the pipeline 16 respectively. It is connected to the pipeline, and the other end is a reduced-diameter structure equipped with blind plates 1A, 1B and anti-collision airbags 15A, 15B; two pigs are arranged in the cylinder, which are called the first pig 6 and the second pig respectively. The pig 10, at this time, the opening and outlet on the upper part of the cylinder should ensure that the water or compressed air in the pipeline and between the pigs can be discharged to prevent air dead ends.

[0105] Therefore, at this time, the upper part of the cylinder is provided with the first inlet 3A, 3B, the second inlet 8A, 8B, the third inlet 11A, 11B, the first outlet 5A, 5B and the second outlet 9A, 9B; the first inlet 3A is located at On the cylinder between the blind plate 1A and the first pig 6, the first outlet 5A is located on the cyli...

Embodiment 3

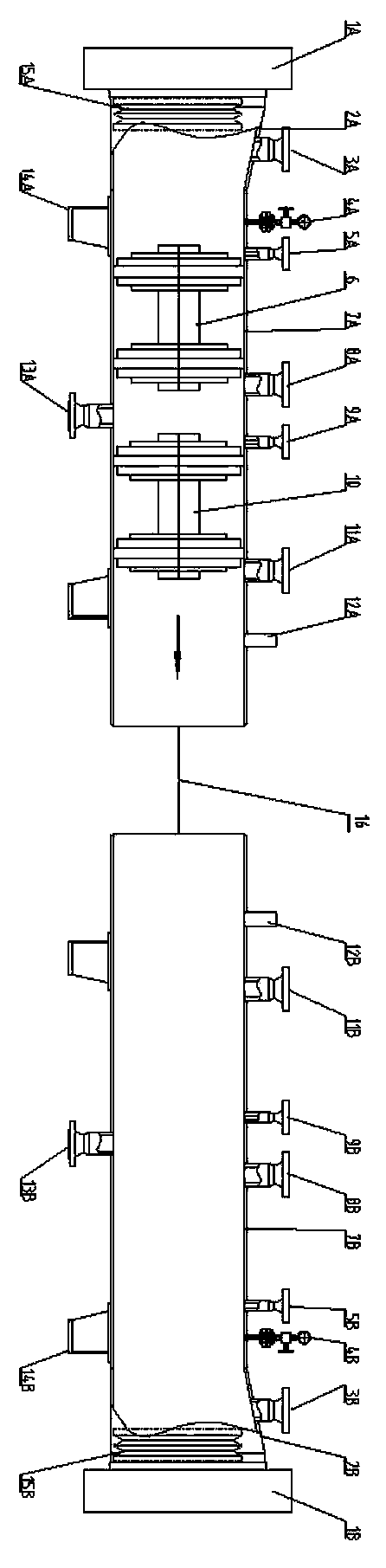

[0135] The pipeline pigging pressure test device of this embodiment includes two pressure test heads, which are connected to the two ends of the pipeline 16 respectively. It is connected to the pipeline, and the other end is a reduced-diameter structure equipped with blind plates 1A, 1B and anti-collision airbags 15A, 15B; two pigs are arranged in the cylinder, which are called the first pig 6 and the second pig respectively. The pig 10, at this time, the opening and outlet on the upper part of the cylinder should ensure that the water or compressed air in the pipeline and between the pigs can be discharged to prevent air dead ends.

[0136] Therefore, at this time, the upper part of the cylinder is provided with first inlets 3A, 3B, second inlets 8A, 8B, first outlets 5A, 5B and second outlets 9A, 9B; the first inlet 3A is located between the blind plate 1A and the first clearing On the cylinder between the pipe cleaners 6, the first outlet 5A is located on the cylinder betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com