Preparation method for strong-adhesion-force carbon nanotube flexible transparent conductive thin film and adhesion force detection method

A technology of transparent conductive film and carbon nanotube film, which is applied in the direction of cable/conductor manufacturing, circuit, measuring device, etc. It can solve the problem of difficult direct test of carbon nanotube adhesion, low adhesion, and uneven uniformity of inner carbon nanotubes. To achieve the effect of easy implementation, simple operation process and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

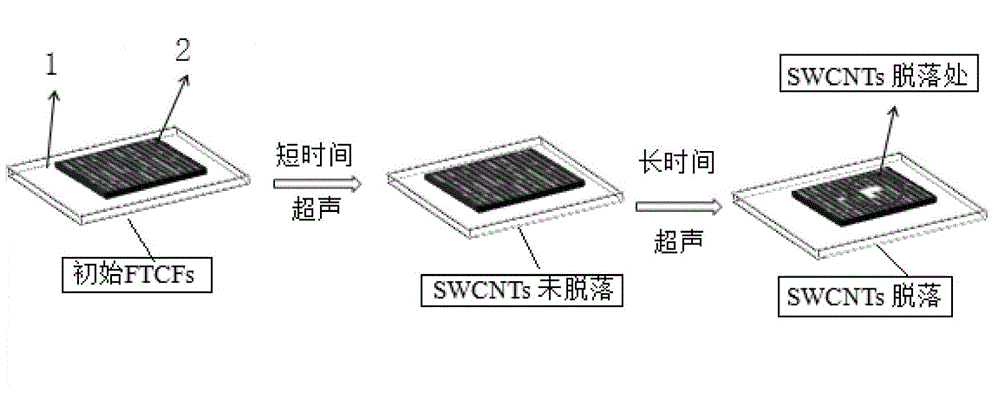

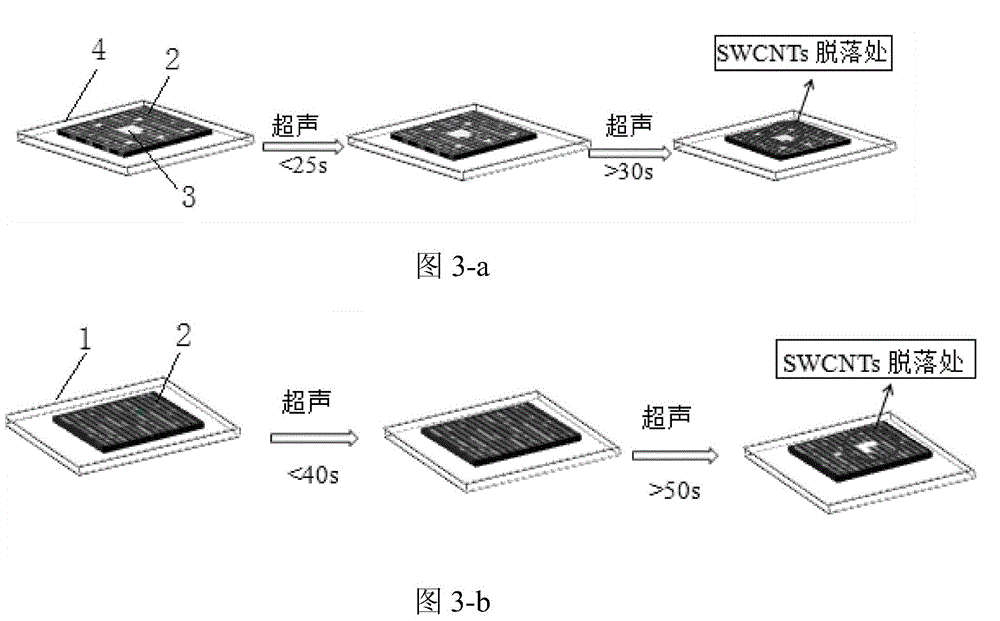

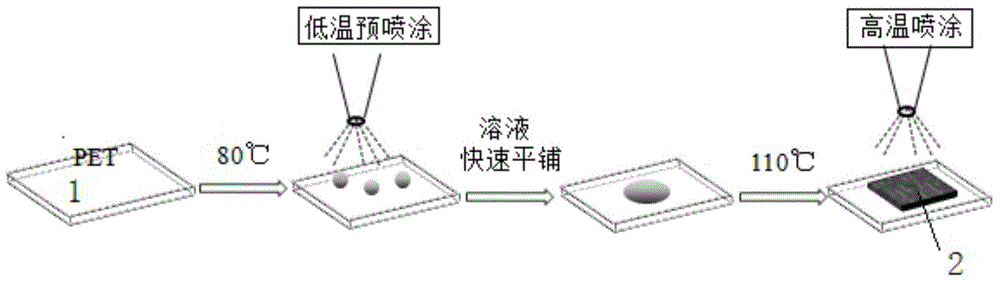

[0036] One, such as figure 1 Shown: a kind of preparation method of the carbon nanotube flexible transparent conductive film of strong adhesion, comprises the steps:

[0037] 1. Pretreatment of ethylene terephthalate PET substrate 1:

[0038] ①Put the original PET base into ethanol, soak it ultrasonically at 30-50KHZ, 50-200W for 1-5h, then put it into 2-12M nitric acid and let it soak for 1-5h;

[0039] ② Take out the PET in ① and put it in deionized water for 1-3 hours to remove the nitric acid on the surface of the PET and make the surface of the PET undergo hydrolysis in water;

[0040] ③ Put the PET in ② in a fume hood and let it dry for 10-15 hours.

[0041] 2. Preparation of carbon nanotube solution for spraying:

[0042] ① Weigh carbon nanotube (SWCNTs) 2 powder at a mass ratio of 0.005%, weigh sodium dodecylbenzenesulfonate (SDBS) 3 at a mass ratio of 0.5%, dissolve in 100ml deionized water, and Sonicate for 1.5h at 100W power in the washer, and then 1h at 120W po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com