Continuous micro water amount irrigation pipe, manufacturing method, usage method and application thereof

An irrigation pipe and micro-water technology, applied in the field of irrigation, can solve problems such as unfavorable growth of crops, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

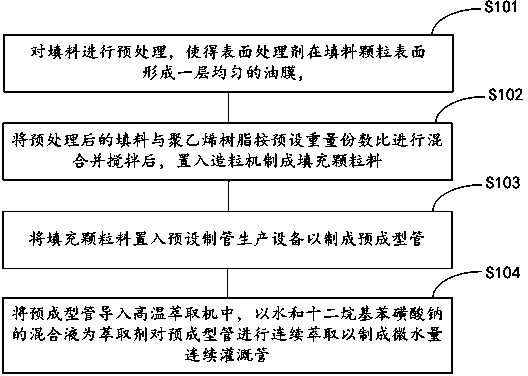

[0108] 1. Choose light calcium carbonate as the filler, and use the surface treatment agent AEO with a weight percentage of 8:100 to the filler to pretreat the filler.

[0109] 2. Blend and granulate the pretreated filler and PE resin at a weight ratio of 60:40.

[0110] 3. Put the prepared granules into the pipe production line, and make preformed pipes with the required caliber through extrusion, cooling, sizing, drawing and other processes.

[0111] 4. Lead the preformed tube into a continuous high-temperature extraction machine, and use the extract solution composed of water and sodium dodecylbenzenesulfonate with a weight percentage of 100:1 to carry out continuous extraction at a temperature of 85 ° C, and make a micro-water volume after cooling Continuous irrigation pipe.

[0112] It has been measured that the water yield of the micro-water continuous irrigation pipe is 170ml / m·h, which is a high-water-yield micro-water continuous irrigation pipe, and is suitable for m...

example 2

[0115] The only difference from the procedure described in Example 1 is that the pretreated filler and PE resin are blended and granulated at a weight ratio of 40:60.

[0116] It has been determined that the water yield of the micro-water continuous irrigation pipe produced by this method is 80ml / m·h, which is a low-water-volume continuous micro-water irrigation pipe, and is suitable for micro-water continuous irrigation of crops with low water demand.

example 3

[0118] Reduce the amount of surface treatment agent AEO in the above case 1 to 2% (that is, the weight percentage with filler is 2:100).

[0119] It is determined that the micro-water volume continuous irrigation pipe produced by the method has a small micropore diameter, and the distribution range of the pore diameter is reduced to 10-300nm. As the diameter of the water outlet channel becomes smaller, when the pressure is 2 meters, the water output per unit time of the micro-water continuous irrigation pipe drops to 20-30ml / m·h, and a higher water source pressure is required to increase the water output. Therefore, this micro-water continuous irrigation pipe is suitable for the situation that tap water is used as the water source and the high pressure of the water source is used for irrigation, such as family garden irrigation and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com