Method for preparing graphene through acetylacetone reduction

A technology of acetylacetone and graphene, applied in graphene, nano carbon and other directions, can solve problems such as environmental hazards, and achieve the effects of low cost, low toxicity and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

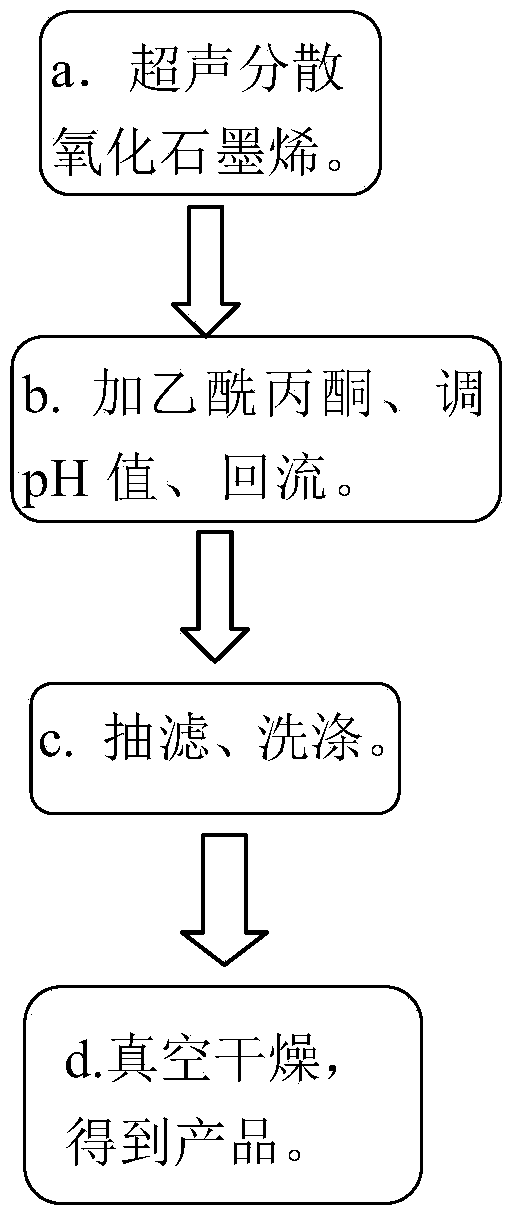

[0025] figure 1 It is a schematic diagram of the overall process for preparing graphene by reduction of acetylacetone in the present invention.

[0026] Weigh 0.1g of graphene oxide into a beaker, add 250ml of deionized water, and ultrasonically disperse it completely; then transfer the graphene oxide aqueous solution into a round bottom flask, add 2ml of acetylacetone, and adjust the pH to 10 through concentrated ammonia water. Reflux for 24 hours; filter with suction, wash with methanol, acetone, and methanol in turn, and finally dry in vacuum to obtain graphene powder.

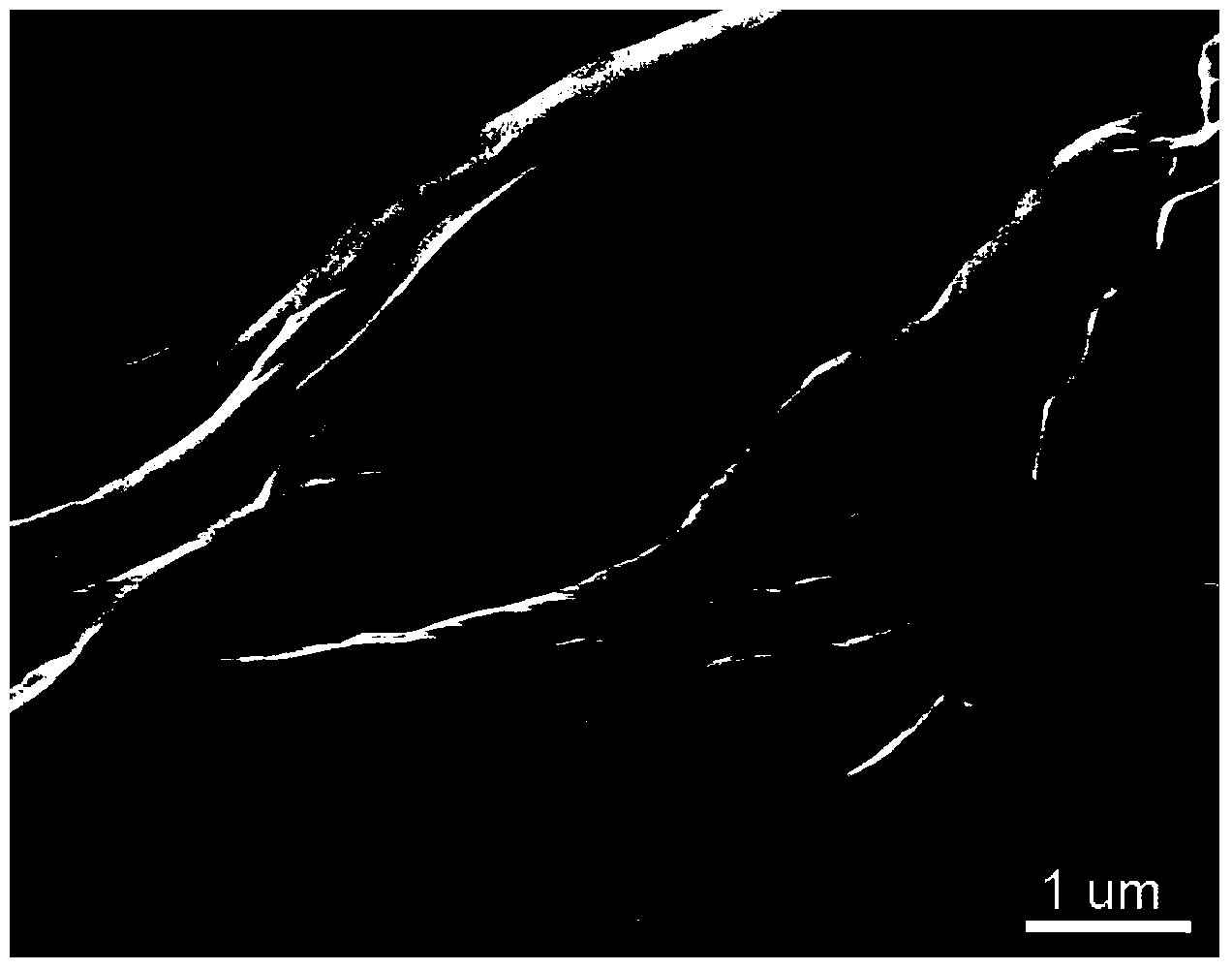

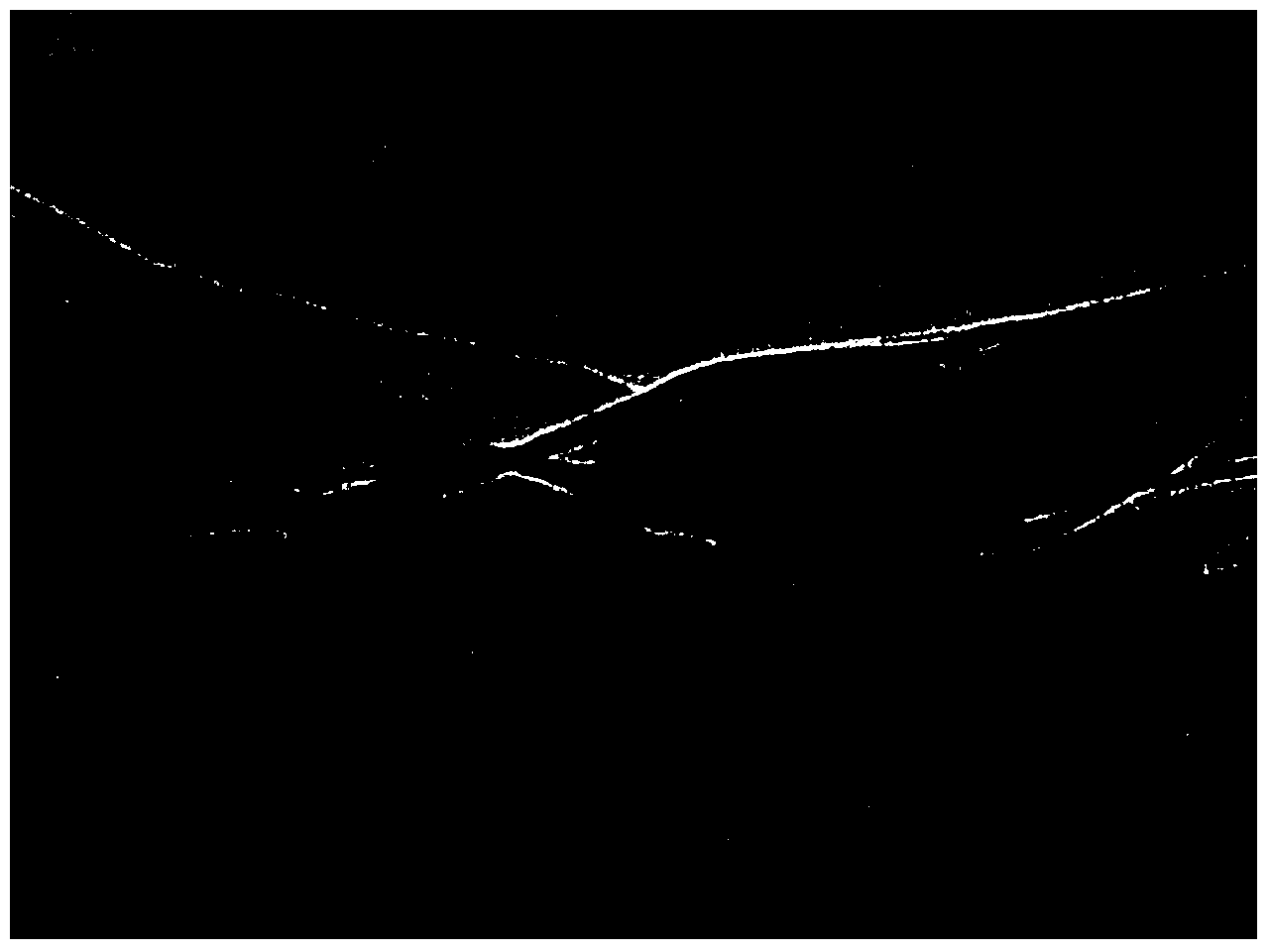

[0027] figure 2 is a scanning electron microscope image of graphene, image 3 is a transmission electron microscope image of graphene, from figure 2 and image 3 The obvious two-dimensional sheet structure of graphene can be seen. Figure 4 is the atomic force microscope photo and thickness value curve of graphene, from Figure 4 It can be seen that the length of the graphene sheet is between 0.5 an...

Embodiment 2

[0029] Weigh 0.5g of graphene oxide into a beaker, add 500ml of deionized water, and ultrasonically disperse it completely; then transfer the graphene oxide aqueous solution into a round bottom flask, add 10ml of acetylacetone, and adjust the pH to 10 through concentrated ammonia water. Reflux for 30 hours; filter with suction, wash with methanol, acetone, and methanol in turn, and finally dry in vacuum to obtain graphene powder.

Embodiment 3

[0031] Weigh 0.3g of graphene oxide in a beaker, add 350ml of deionized water, and ultrasonically disperse it completely; then transfer the graphene oxide aqueous solution into a round bottom flask, add 7ml of acetylacetone, and adjust the pH to 10 through concentrated ammonia water. Reflux for 28 hours; filter with suction, wash with methanol, acetone, and methanol in turn, and finally dry in vacuum to obtain graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com