Hair-based method for fabricating diamond

A production method and diamond technology, applied in the direction of diamond, etc., can solve the problems of not being able to use hair, making diamonds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

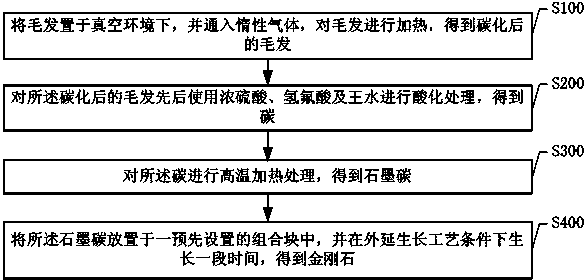

Method used

Image

Examples

Embodiment 1

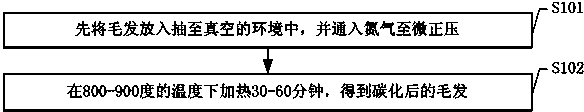

[0092] 101. Take 420 grams of human hair and heat it to 900 degrees, keep it warm for 1 hour under a slight positive pressure in a nitrogen atmosphere, and obtain 57 grams of C calcium phosphorus mixture;

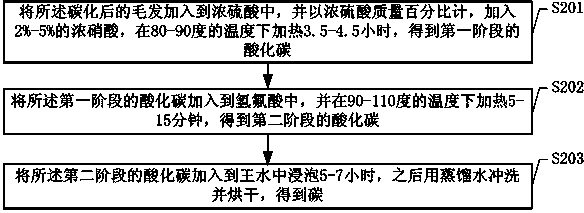

[0093] 102. The mixture was treated and purified with hydrofluoric acid sulfuric acid and aqua regia step by step as described in steps S201-S203 to obtain 46 grams of pure carbon;

[0094] 103. Heating in a high-temperature graphitization furnace under a slight positive pressure in a nitrogen atmosphere at 2800°C for 20 minutes to obtain 41.5 grams of graphite with a purity of 4N;

[0095] 104. Add graphite to 20% nickel-manganese-cobalt alloy, mix and press it into flakes, add 10 grains of 0.2 mm seed crystals, and put them into the components shown in the assembly structure diagram;

[0096] 105. Afterwards, use a six-sided top press to grow for 30 hours using the temperature and pressure increase process shown in the epitaxy process curve, and obtain 10 yellow diamonds ...

Embodiment 2

[0098] 201. Take 600 grams of human hair and heat it to 900 degrees, and keep it warm for 0.5 hours under a slight positive pressure in a nitrogen atmosphere to obtain 86 grams of C calcium phosphorus mixture;

[0099] 202. The mixture was purified step by step with hydrofluoric acid sulfuric acid and aqua regia as described in steps S201-S203 to obtain 79 grams of pure carbon;

[0100] 203. Use a Φ200×300 type high-temperature graphitization furnace in a nitrogen atmosphere to graphitize at 3000 degrees for 20 minutes under a slight positive pressure to obtain 71 grams of graphite with a purity of 4N;

[0101] 204. Add part of the graphite to 20% pure cobalt alloy powder and press it into flakes, implant 4 0.5mm seed crystals, and put them into the components shown in the assembly structure diagram;

[0102] 205. Using a six-sided top press to grow for 44 hours using the temperature-increasing and pressure-increasing process shown in the epitaxy process curve, four golden yel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com