UV curing primer for vacuum coating and UV curing paint for vacuum coating

A vacuum coating and ultraviolet light technology, applied in the field of chemical coatings, can solve the problems of poor film-forming effect of primers, and achieve the effect of ensuring full curing and good working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

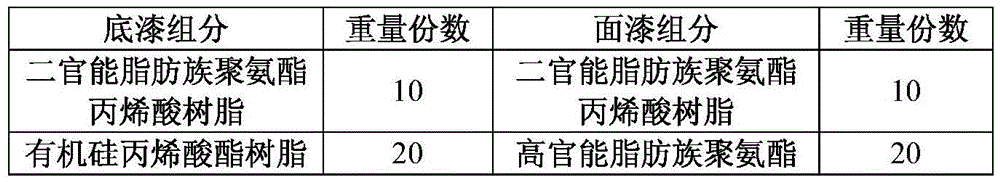

Embodiment 1~7

[0049] The coating curing method of embodiment 1~7 finish paint, primer:

[0050] a) Spray the UV-curable primers in Examples 1 to 7 on the PC substrate with wire drawing after pretreatment, the coating film thickness is 1 μm, leveling under the irradiation of infrared lamp at 50°C for 5 minutes, 800mJ / cm 2 energy curing;

[0051] b) then vacuum coating;

[0052] c) Spray the UV-curable topcoat in Examples 1 to 7 on the vacuum coating, the coating film thickness is 20 μm, leveling under the irradiation of infrared lamp at 60°C for 7 minutes, and giving 1100mJ / cm 2 Energy hardened.

[0053] The pretreatment steps of the UV-curable primer in Examples 1 to 7 are:

[0054] a) Preheating the acrylic group-containing resin in the UV-curable primers of Examples 1-7 at 40-50° C. for 1-2 hours, and dissolving it with 2 / 3 volume of diluent to obtain the first solution;

[0055] b) Add the photoinitiator and adhesion promoting resin in the UV-curable primer of Examples 1-7 to the fir...

Embodiment 7

[0076] The difference from Example 6 is that the topcoat is prepared by mixing the topcoat formulation disclosed in CN201210332439.5, wherein the adhesion promoter is vinyl chloride-vinyl acetate copolymer containing hydroxyl groups. The photoinitiator in the primer is photoinitiator-184, and the adhesion promoting resin is a special polyester resin.

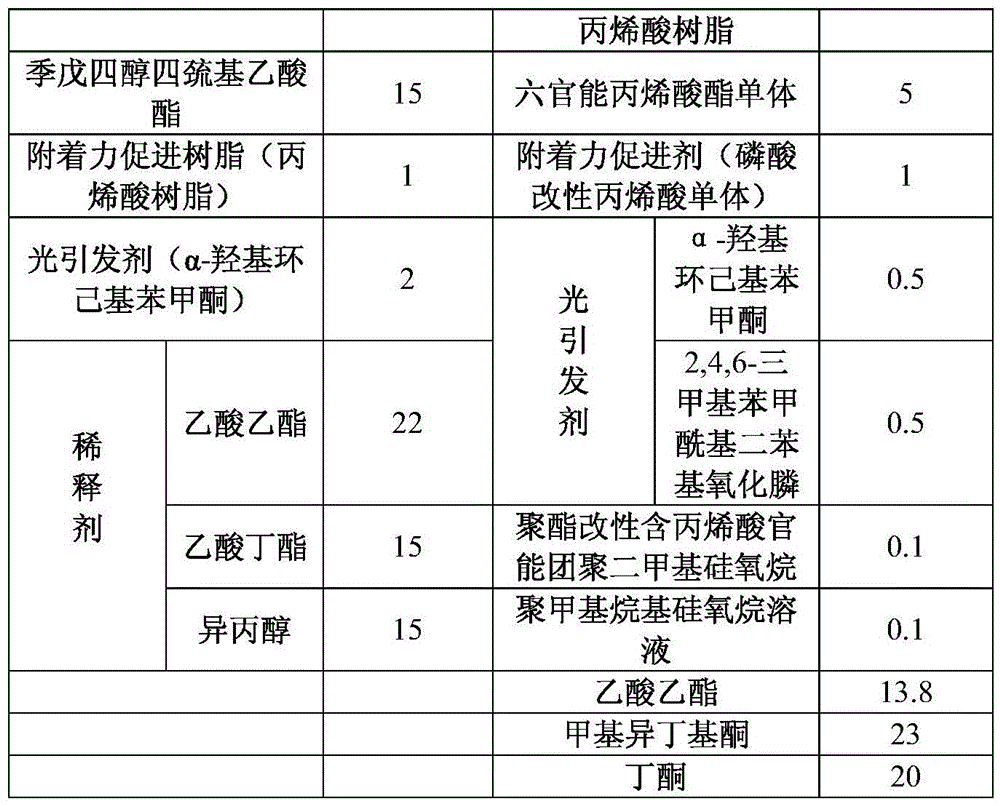

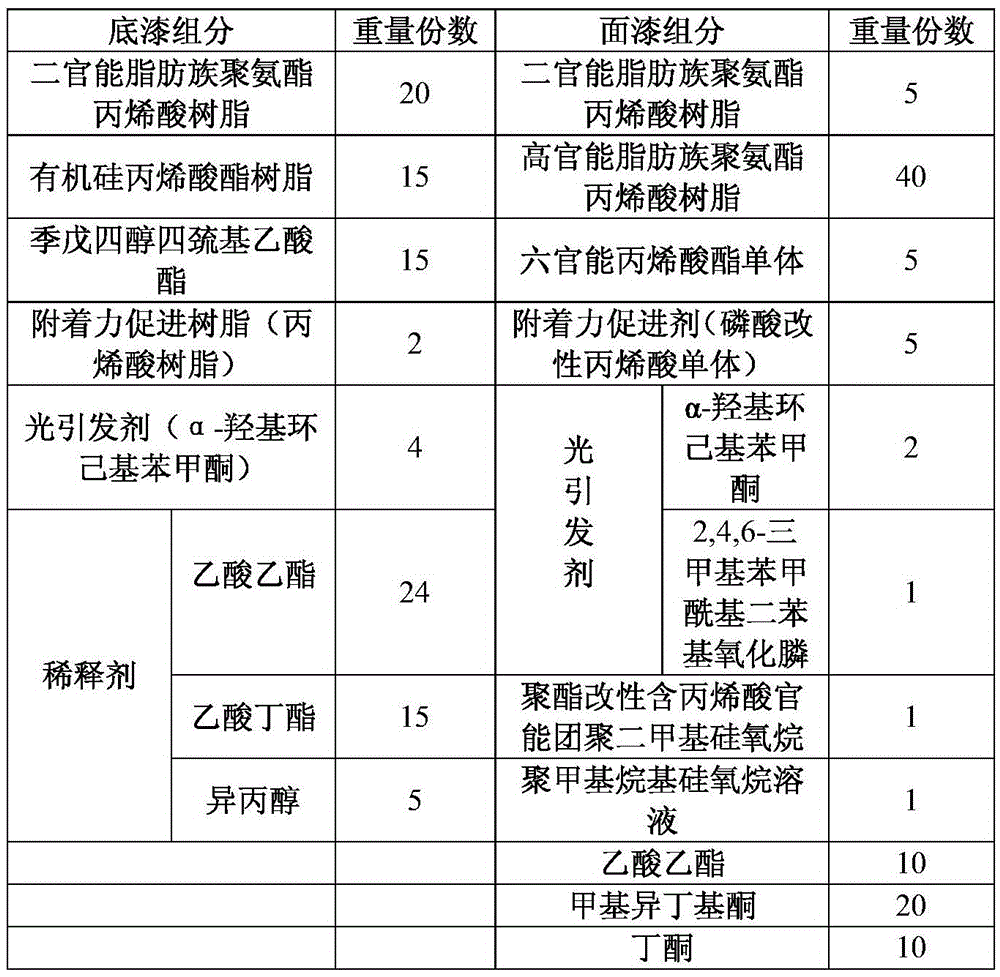

[0077] The parts by weight of each component of primer in Table 7 Comparative Example 1

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com