Continuous thermal-cracking method and apparatus for waste and old tires

A waste tire and thermal cracking technology, which is applied in the preparation of liquid hydrocarbon mixture, fibrous filler, petroleum industry, etc., can solve the problems of unsatisfactory carbon black quality, energy waste, environmental pollution, etc., and achieve continuous production saving and activity improvement and quality, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

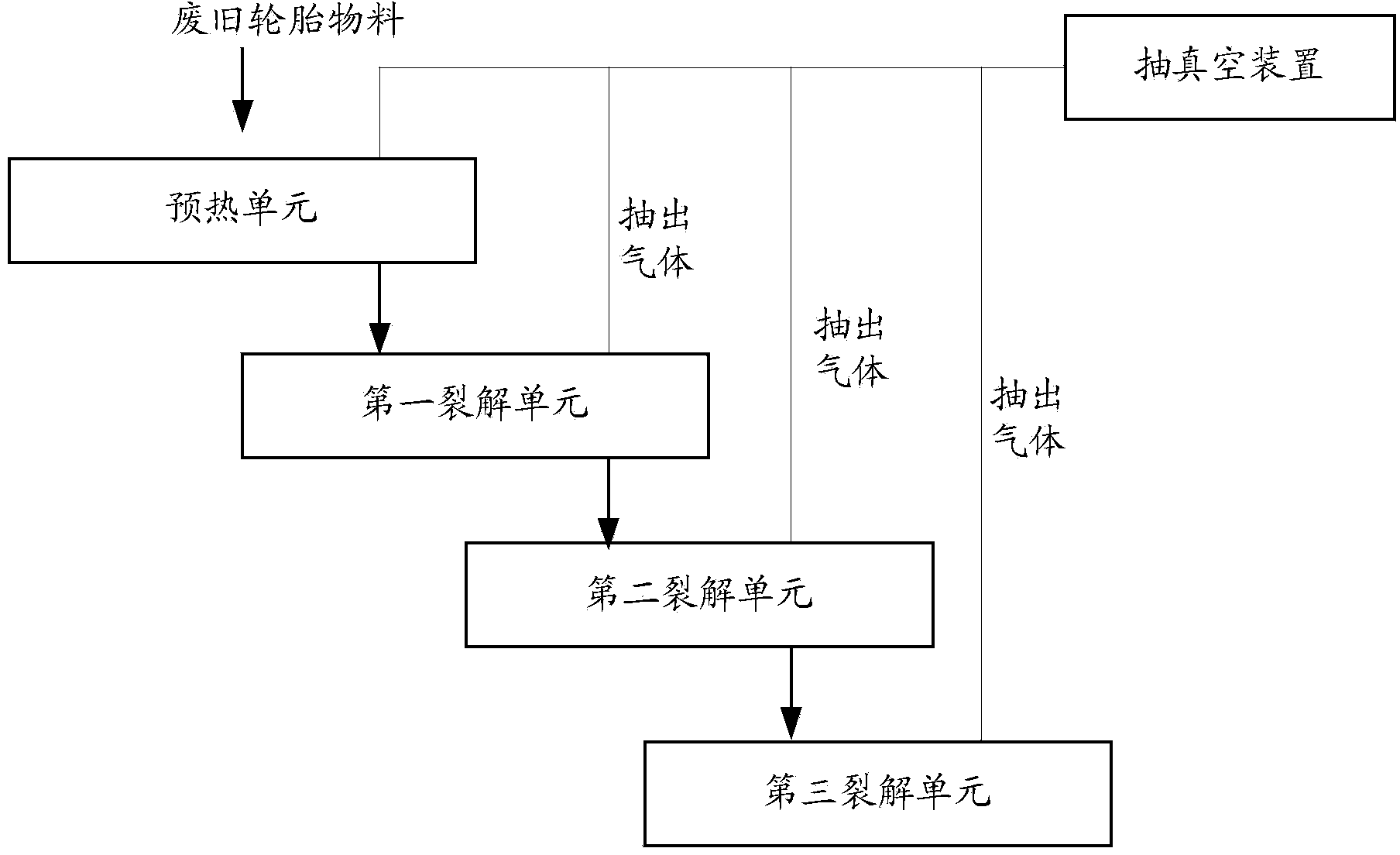

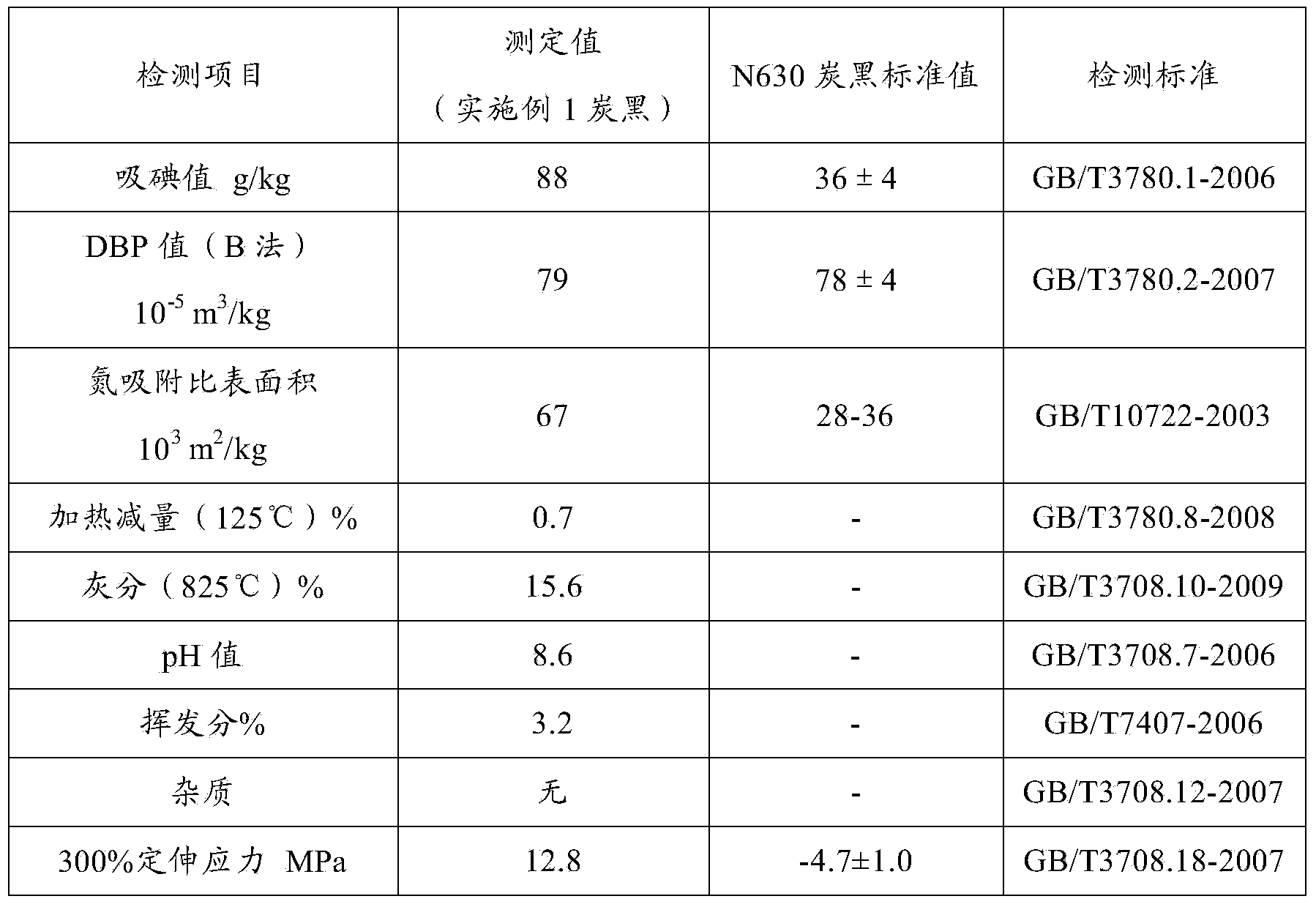

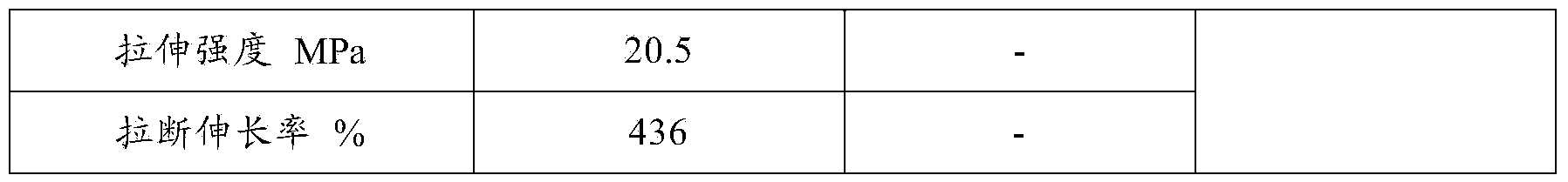

[0035] The waste tire continuous subsection pyrolysis method of the present invention adopts figure 1The pyrolysis furnace shown. This furnace is divided into four units. The preheating unit is mainly to preheat the small rubber blocks with steel wires formed after processing waste tires and make them soft and viscous. This unit preheats the rubber blocks to about 240°C. The running time of the material is about 20 minutes; then the material enters the first cracking unit, which first raises the temperature of the material to about 350°C at an average heating rate of 10°C / min, and then heats it at about 350°C for about 10 minutes; then the material enters the second cracking unit , this unit first raises the temperature of the material to about 450°C at an average heating rate of 10°C / min, and heats it at about 450°C for about 10 minutes; after that, the material enters the third cracking unit, which first heats the material at an average rate of 10°C / min The heating rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com