Wind circulation intelligent thawing-in refrigerator

An air circulation and intelligent technology, applied in household refrigerators, cooling fluid circulation devices, coolers, etc., can solve problems such as poor taste, no time to thaw and cook, and inconvenient thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

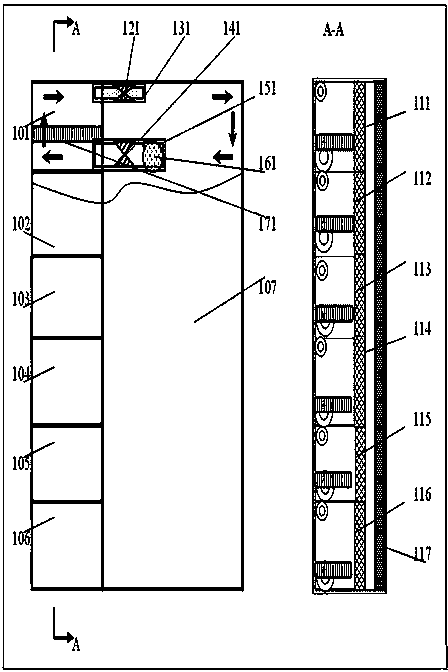

[0023] The structure of air circulation smart thawing refrigerator is as follows: figure 1 As shown, it is divided into a plurality of freezing chambers 101-106 and refrigerating chambers 107, and the single-chip microcomputer system independently controls the temperature of each freezing chamber 101-106 and refrigerating chamber 107. In the hot layer, each freezer has a private airtight door 111-116, and all freezers have a common airtight door 117. When storing frozen food in the freezer 101, the common airtight door 117 is opened first, and then the freezer 101 is opened. Private airtight door 111, the airtight door 112-116 privately owned by other freezing chambers 102-106 is not opened, reducing cold leakage. The freezing chamber, the refrigerating chamber and the refrigerator shell are provided with temperature sensors respectively, and they are connected with the single-chip microcomputer to measure the temperatures of the freezing chamber, the refrigerating chamber an...

Embodiment approach 2

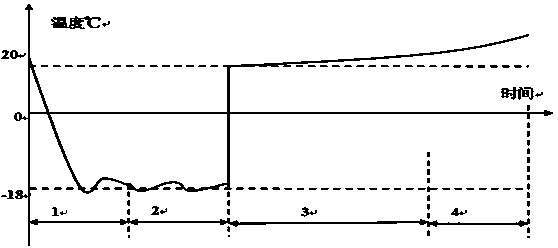

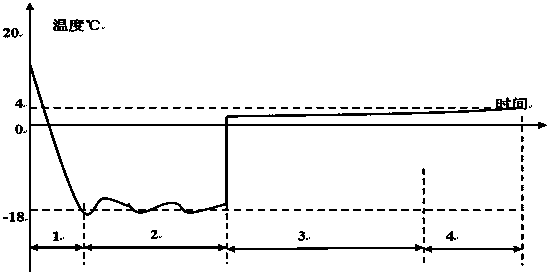

[0031] Implementation mode 2: Air circulation intelligent thawing refrigerator experimental system and its experimental results.

[0032] Refrigerator controllers are designed such as Figure 5 The structure diagram of the temperature control system of the refrigerator is shown in the figure. The hardware of the controller system includes a thermistor sensor, an amplifier circuit, a multiplexer, a single-chip microcomputer, a multiplexer, a solenoid valve, an air pump, buttons, a liquid crystal screen, a voice module or a light-emitting diode, and a buzzer. The temperature sensors 1-6 measure the temperature of the freezer compartments 101-106, the temperature sensor 7 measures the temperature of the refrigerator compartment 107, and the temperature sensor 8 measures the temperature of the outer shell of the refrigerator. Solenoid valves C1-C6 (not shown in the figure) control the flow of the refrigerant in the freezing chamber 101-106, and solenoid valve C7 (not shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com