A method of equipment logic control based on plc/dcs

A technology of logic control and equipment, applied in the direction of total factory control, electrical program control, comprehensive factory control, etc., can solve the problems of heavy workload of program design, development and maintenance, long design and development cycle, complex logic chain relationship, etc. , to reduce the workload of logic control design and development, reduce the difficulty of testing and on-site debugging, and reduce the effect of professionals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

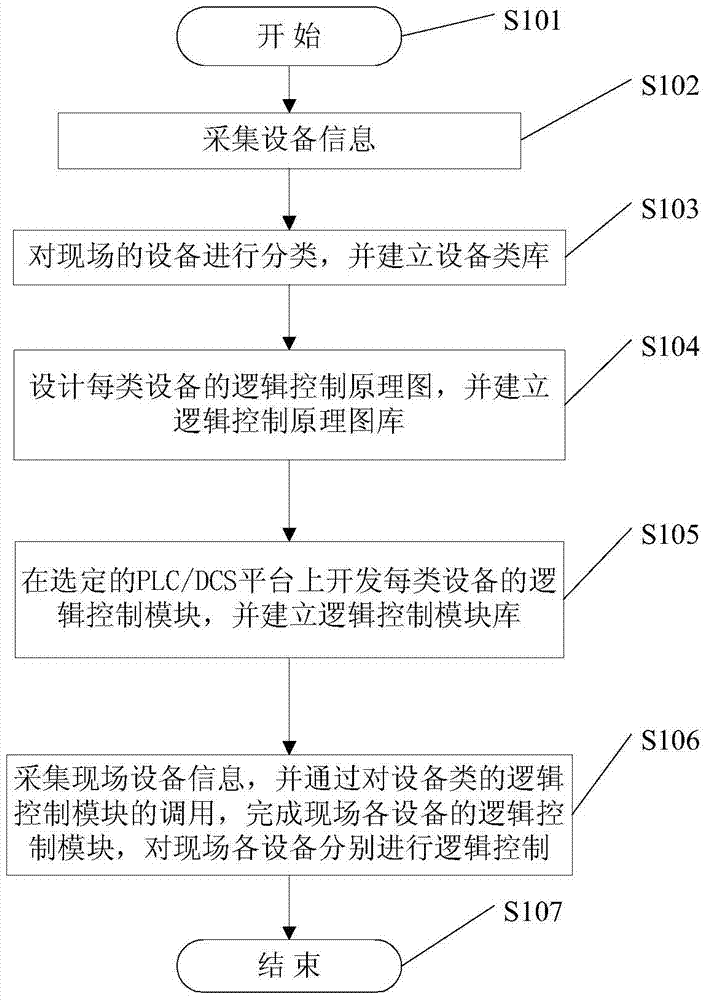

[0032] The equipment logic control method based on PLC / DCS of the present embodiment, such as figure 1 As shown, taking a foreign large-scale DCS project as an example, the control system of this project covers the whole plant and involves 18 sub-processes of the whole plant. Interlock control of fuel supply, etc. The scale of the entire control system is relatively large, with more than 11,500 I / O points, and more than 1,600 devices that need to realize logic control, including various motors, valves, and large-scale equipment. The control system adopts the PKS product of Honeywell Company. Since there are a lot of equipment involved, this implementation mode uses a typical process as an example to describe the implementation process of this implementation mode, and the specific process starts from step 101 .

[0033] In step 102, equipment infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com