High-power fluorescent lamp

A high-power fluorescent lamp and fluorescent powder technology, which is applied to the parts and components of gas discharge lamps, can solve the problems of high cost, high mercury vapor pressure, and harm to the health of operators, and achieve the effect of short life and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

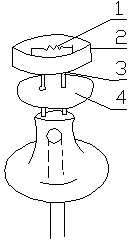

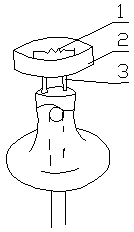

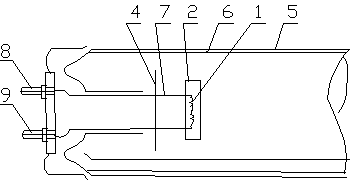

[0024] Fig. 1 is the best embodiment of the wick structure of the high-power fluorescent lamp of the present invention. Below in conjunction with accompanying drawing, high-power fluorescent lamp of the present invention is described in further detail: as figure 1 The wick structure of the high-power fluorescent lamp shown is installed in image 3 In the lamp tube 5, the use effect is the best.

[0025] Compared with the prior art, the advantages of the high-power fluorescent lamp of the present invention are: 1. Adopting the ring-shaped anode structure, the structure is simple, easy to manufacture, and there are few solder joints. The heat shield is removed, and there are only 2 solder joints, which greatly improves the Improve labor efficiency, reduce costs, and increase pass rate by more than 100%.

[0026] 2. Titanium amalgam zirconium aluminum 16 getter belt is used as annular anode, because the saturated vapor pressure of amalgam is much lower than that of pure amalg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com