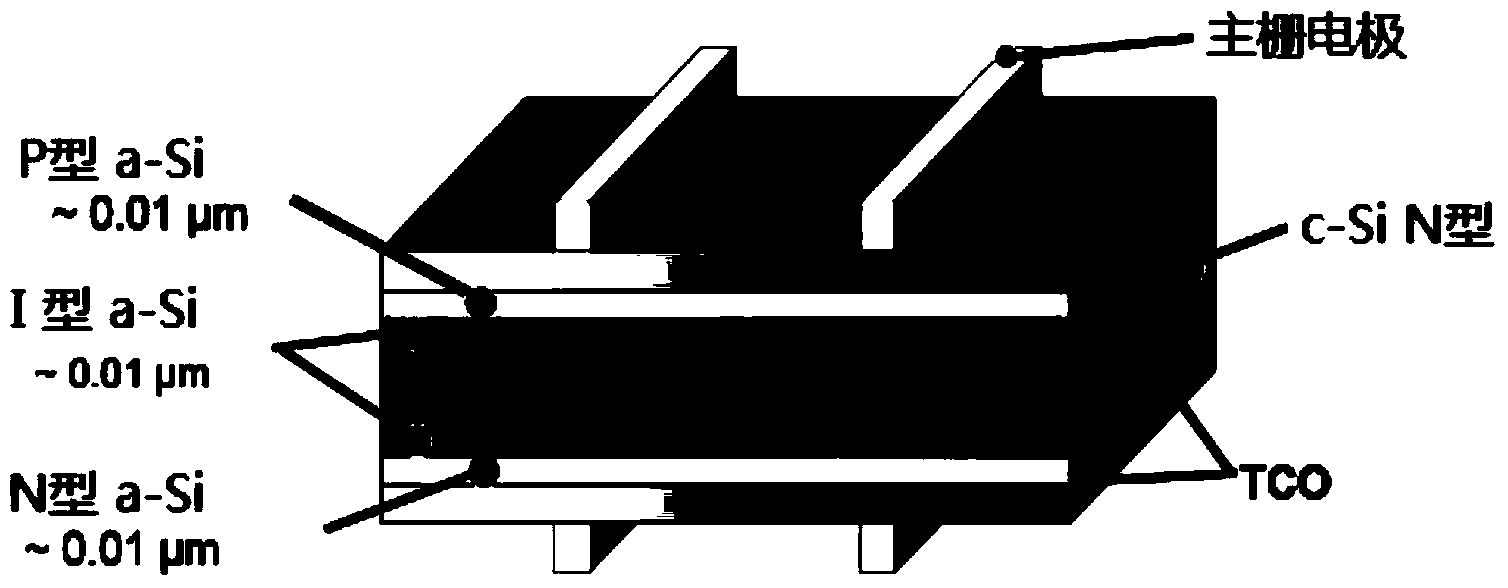

HIT (Heterojunction with Intrinsic Thin Layer) solar cell and electrode preparation and series connection methods thereof

A technology of solar cells and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the fill factor of solar cells, high technical threshold of conductive silver glue, and low conductivity of conductive silver glue, so as to improve the photoelectricity Conversion efficiency, save screen printing process, save the effect of conductive silver glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

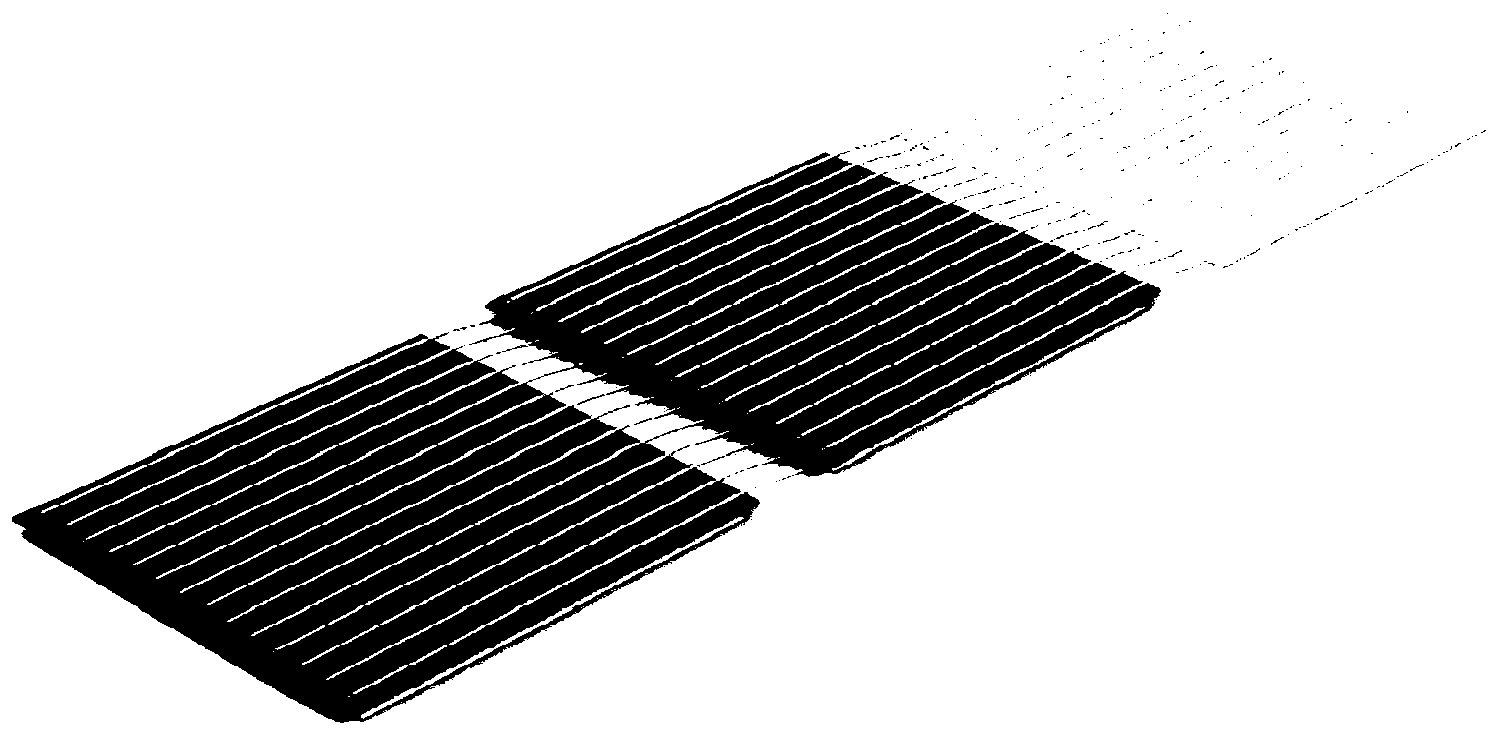

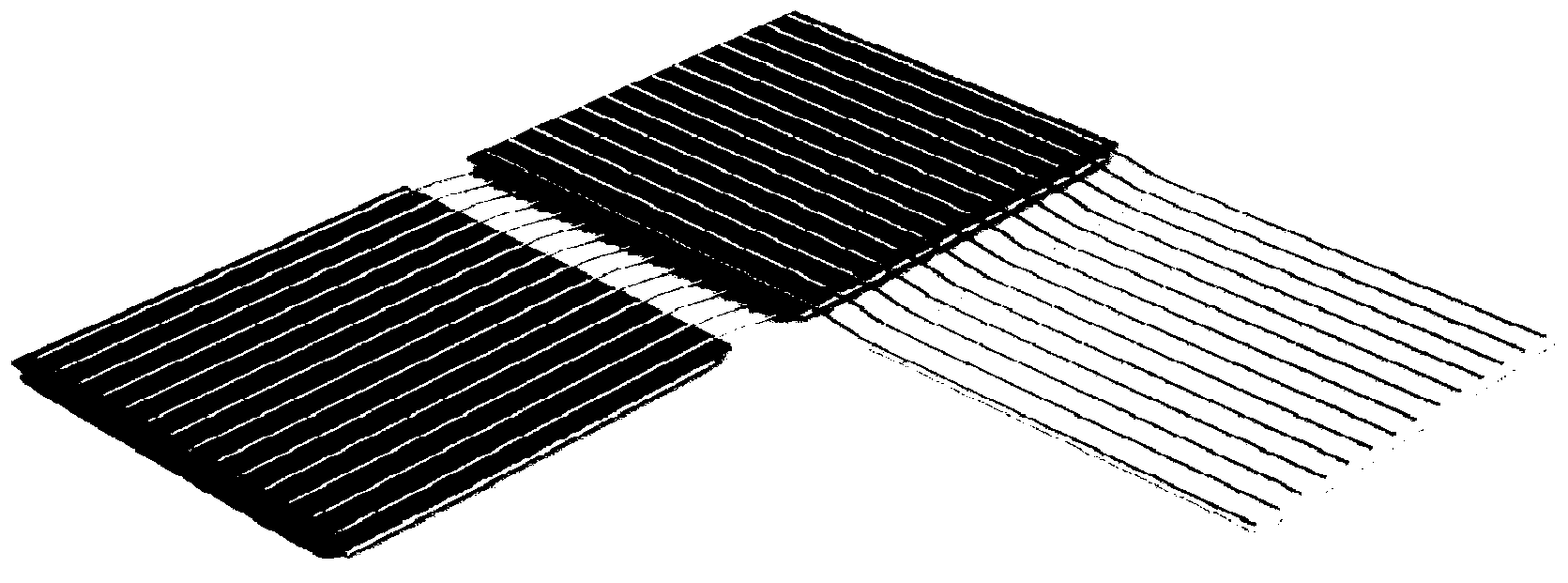

[0042] see Figure 2 to Figure 8 , a method for preparing and connecting electrodes of a HIT solar cell, comprising the following steps:

[0043]1) Arrange the metal wires in parallel to connect two composite films containing two layers of PET and EVA materials. The first half of the metal wire is attached to the bottom of a piece of composite film, and the EVA side of the composite film is in contact with the metal wire. The second half of the metal wire Partially attached to another piece of composite film, and the EVA side of the composite film is in contact with the metal wire, and the edges of the two composite films are close to each other, thereby preparing a conductive strip, wherein the composite film is the same size as the solar cell sheet, and the metal wire Twice as long as sola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com