Polytetrafluoroethylene diaphragm for preparing hydrogen for fuel cell, and preparation method thereof

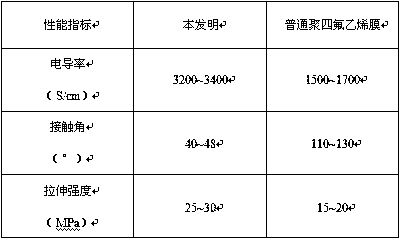

A polytetrafluoroethylene, fuel cell technology, applied in the direction of organic diaphragm, electrolysis process, electrolysis components, etc., can solve the problems of poor mechanical properties, poor hydrophilicity, low conductivity, etc., to achieve good mechanical properties, easy compounding, The effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

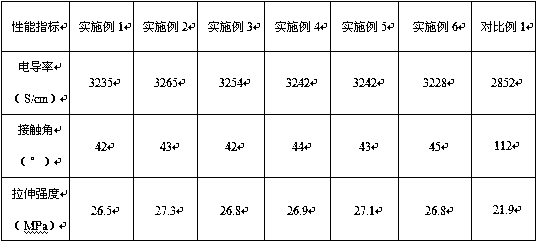

Examples

Embodiment 1

[0031] (1) The polytetrafluoroethylene microporous membrane is prepared by bidirectional melt stretching, and then placed in a sodium naphthalene tetrahydrofuran solution, and part of the fluorine atoms on the surface of polytetrafluoroethylene are detached by reaction, exposing the carbon-based surface and polar groups After black spots appear on the surface of the membrane material, the membrane material is taken out, washed 3 to 5 times with deionized water, and dried to obtain an activated polytetrafluoroethylene microporous membrane; the stretching ratio of the polytetrafluoroethylene microporous membrane is 3.5 times; the mass concentration of sodium naphthalene tetrahydrofuran solution is 40%; the temperature of reaction is 60 ℃, and the time is 50min;

[0032] (2) Blend the activated polytetrafluoroethylene microporous membrane prepared in step (1) with methylvinyloxyethyltrimethylammonium chloride in an organic solvent, add additives, seal, and use Co 60 Carry out irr...

Embodiment 2

[0035] (1) The polytetrafluoroethylene microporous membrane is prepared by bidirectional melt stretching, and then placed in a sodium naphthalene tetrahydrofuran solution, and part of the fluorine atoms on the surface of polytetrafluoroethylene are detached by reaction, exposing the carbon-based surface and polar groups After black spots appear on the surface of the membrane material, the membrane material is taken out, washed 3 to 5 times with deionized water, and dried to obtain an activated polytetrafluoroethylene microporous membrane; the stretching ratio of the polytetrafluoroethylene microporous membrane is 3 times; the mass concentration of sodium naphthalene tetrahydrofuran solution is 50%; the temperature of reaction is 50 ℃, and the time is 70min;

[0036] (2) Blend the activated polytetrafluoroethylene microporous membrane prepared in step (1) with methylvinyloxyethyltrimethylammonium chloride in an organic solvent, add additives, seal, and use Co 60 Carry out irrad...

Embodiment 3

[0039] (1) The polytetrafluoroethylene microporous membrane is prepared by bidirectional melt stretching, and then placed in a sodium naphthalene tetrahydrofuran solution, and part of the fluorine atoms on the surface of polytetrafluoroethylene are detached by reaction, exposing the carbon-based surface and polar groups After black spots appear on the surface of the membrane material, the membrane material is taken out, washed 3 to 5 times with deionized water, and dried to obtain an activated polytetrafluoroethylene microporous membrane; the stretching ratio of the polytetrafluoroethylene microporous membrane is 3.5 times; the mass concentration of sodium naphthalene tetrahydrofuran solution is 45%; the temperature of reaction is 55 ℃, and the time is 60min;

[0040] (2) Blend the activated polytetrafluoroethylene microporous membrane prepared in step (1) with methylvinyloxyethyltrimethylammonium chloride in an organic solvent, add additives, seal, and use Co 60 Carry out irr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com