Multicage-type device for filtering ballast water for automatically controlling sequential backwashing and method for same

A technology of filtering device and ballast water, applied in water treatment device, fixed filter element filter, separation method, etc., can solve the problems of component elements colliding with each other, damage, lack of filter, foreign body damage, etc., to improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

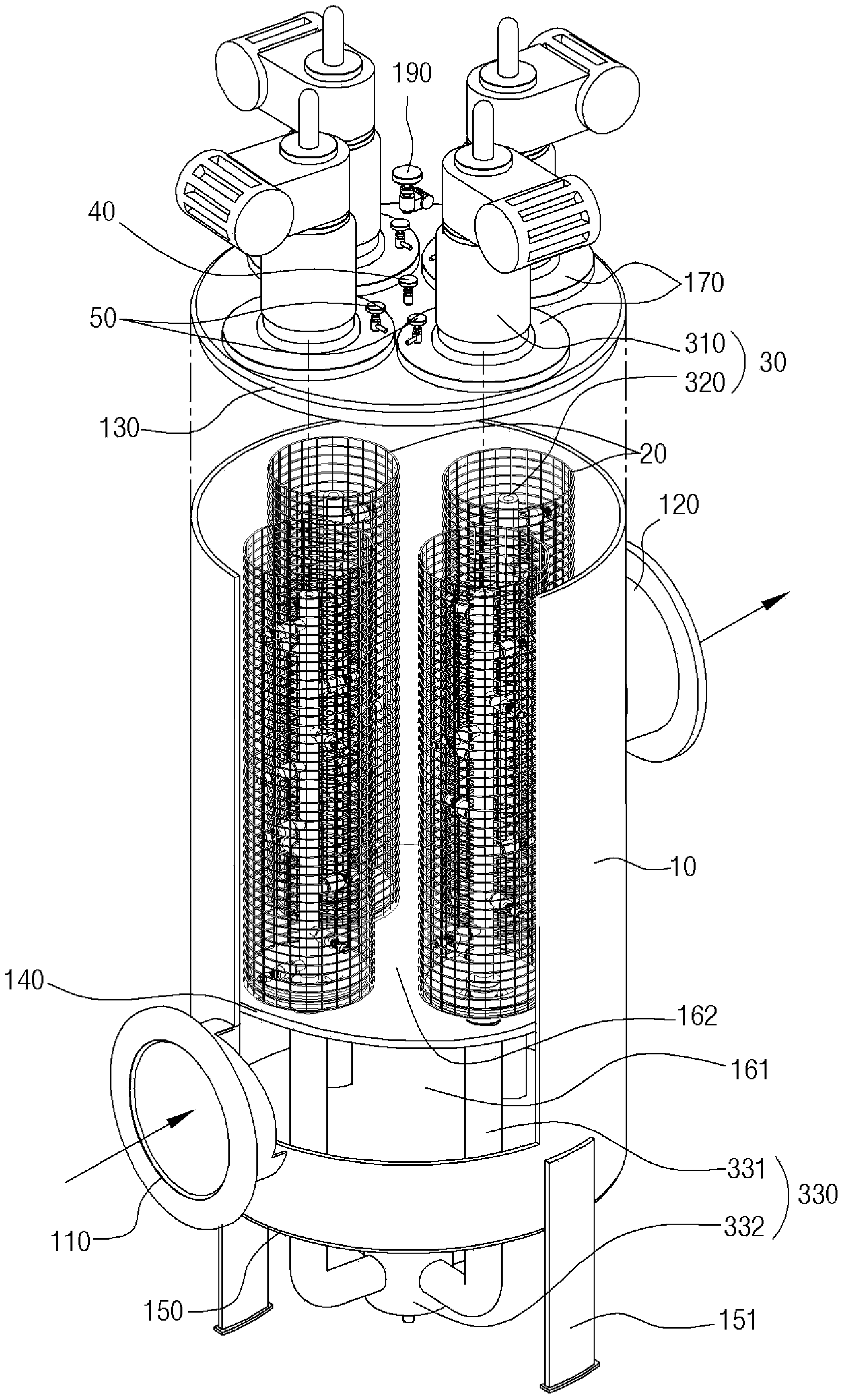

[0063] A preferred embodiment of the multi-cage ballast water filtering device for automatic control for sequential backwashing of the present invention will be described in detail below with reference to the accompanying drawings. In describing the present invention below, detailed descriptions of known structures or functions will be omitted if it is considered that they will unnecessarily obscure the gist of the present invention.

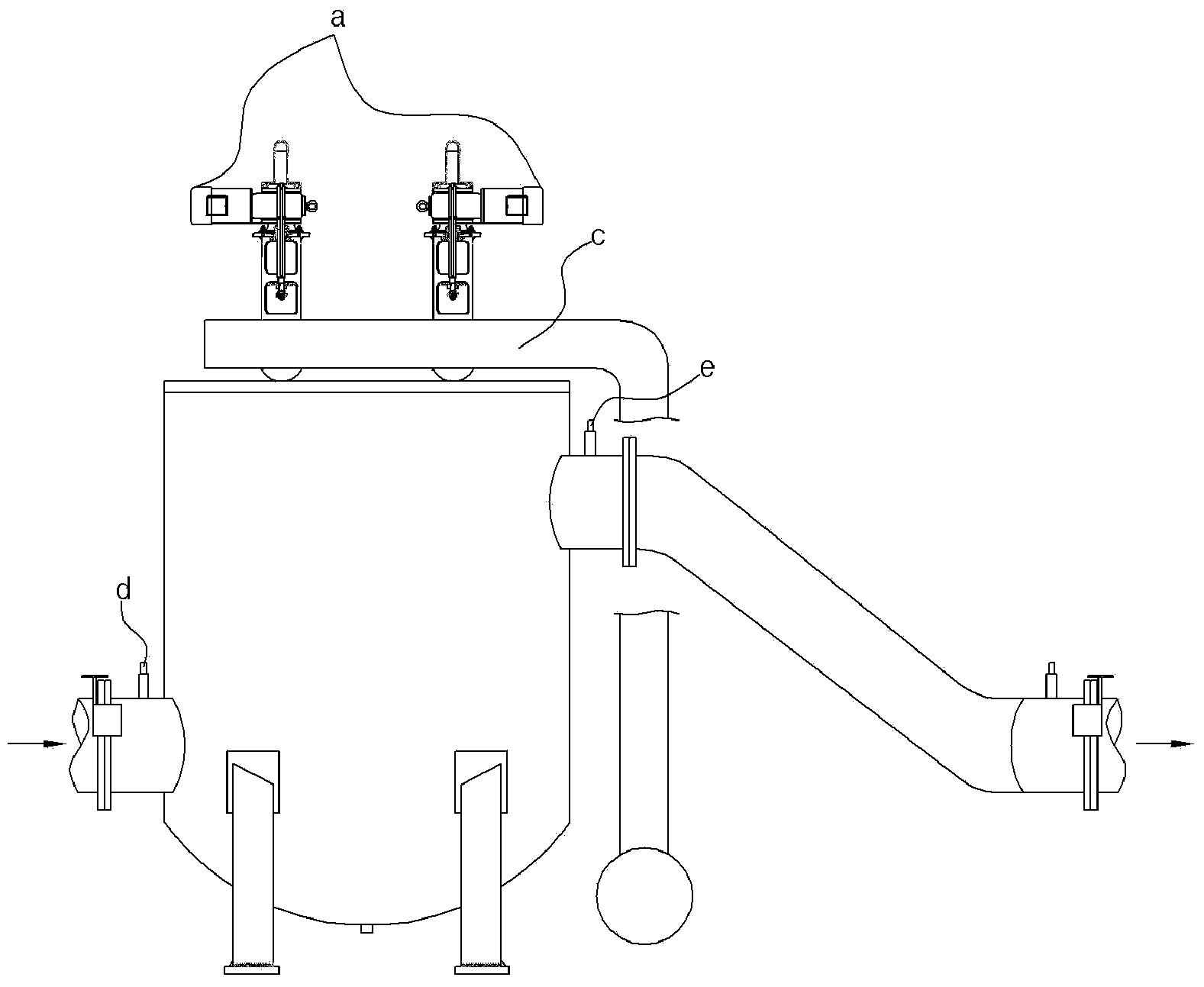

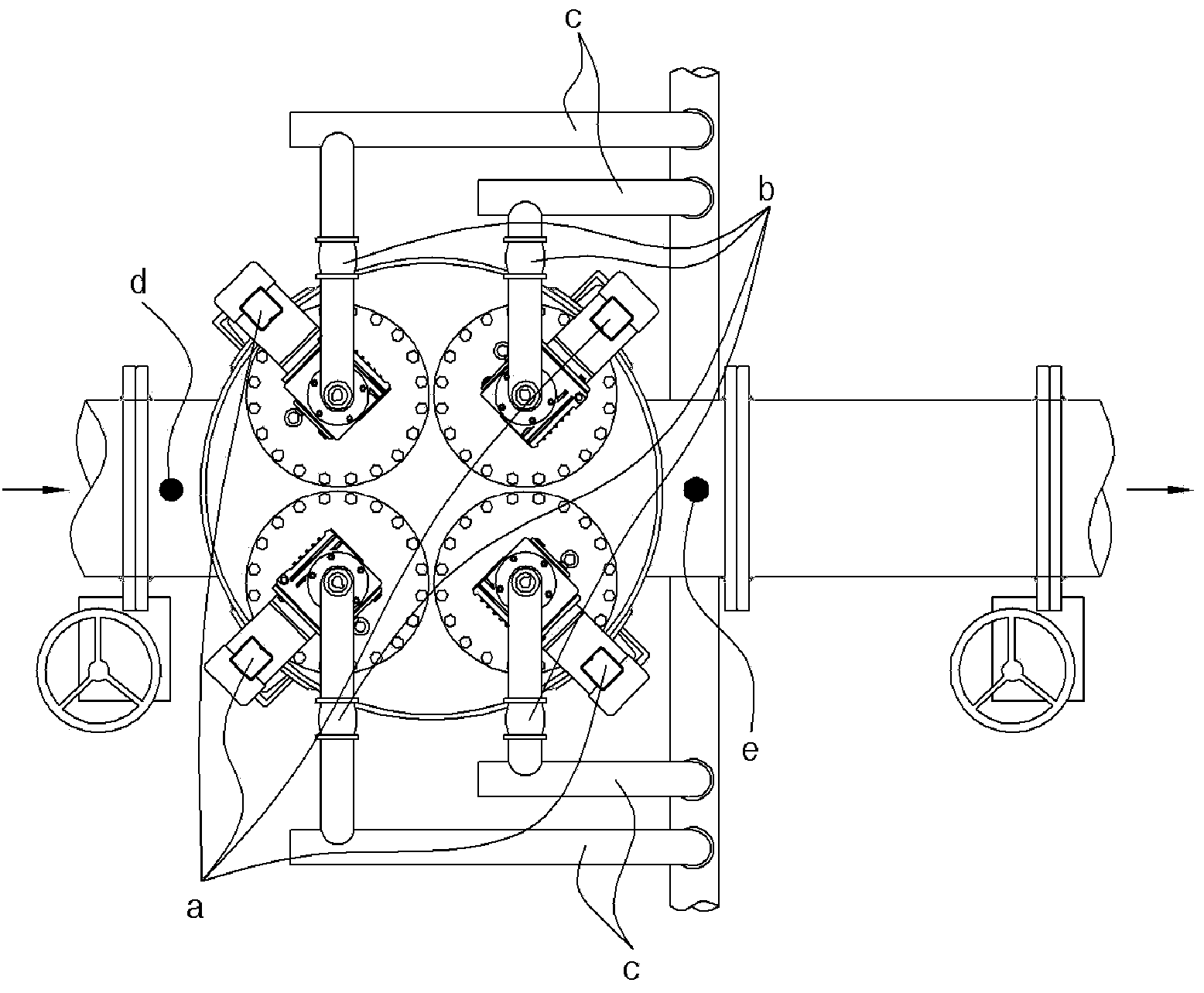

[0064] image 3 It is an exploded oblique view of a multi-cage ballast water filtration device according to an embodiment of the present invention, Figure 4 yes image 3 A cross-sectional view of the filter unit, Figure 5 yes image 3 A top view of the filter unit, Image 6 yes image 3 Bottom view of the filter unit, Figure 7 is a sectional view showing the relationship between the backwash line and the back pressure prevention tank, Figure 8 It shows the relationship between the stopper and the bushing Figure 4 Enlarged view of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com