A kind of zeolite butyric acid powder and its preparation method and application

A zeolite butyric acid powder, zeolite technology, applied in the application, animal feed, additional food elements and other directions, can solve the problems of reducing the intestinal protection effect, failing to reach the latter part of the intestine, reaching butyric acid, etc., to overcome uneven absorption , The effect of reducing the material-to-weight ratio and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A certain amount of zeolite (the content of clinoptilolite in the zeolite is 86%) was weighed and activated in a 350° C. Maof furnace for 3 hours, and then placed in a thermostat for use.

[0027] Prepare 4mol / L butyric acid solution, mix zeolite and butyric acid according to the ratio of 1:14 (the percentage of 4mol / L butyric acid solution is 93.3%, the percentage of zeolite is 6.67%) and place in a magnetic stirrer to heat and stir (The temperature is controlled at about 60°C), the rotating speed is 120 rpm, and the heating and stirring time is 4 hours. After the reaction, let it stand, wash off the unloaded acid ions with distilled water, and filter the solution until the filtrate is neutral. The separated solid material is dried at 90-105° C., and the dried solid material is input into a pulverizer for pulverization, and the particle fineness after pulverization is ≤0.074 mm to obtain zeolite butyric acid powder. ZRY-2P comprehensive thermal analysis instrument was...

Embodiment 2

[0028] The animal test of embodiment 2 zeolite butyric acid powder

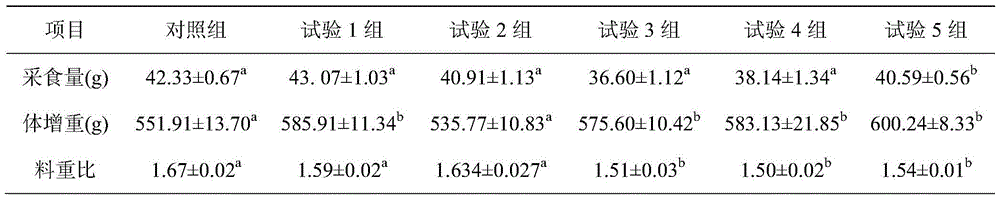

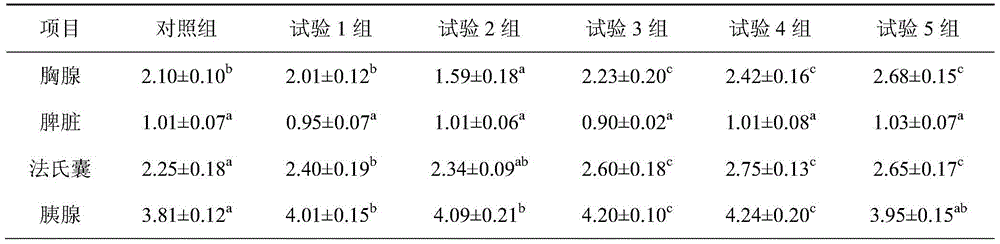

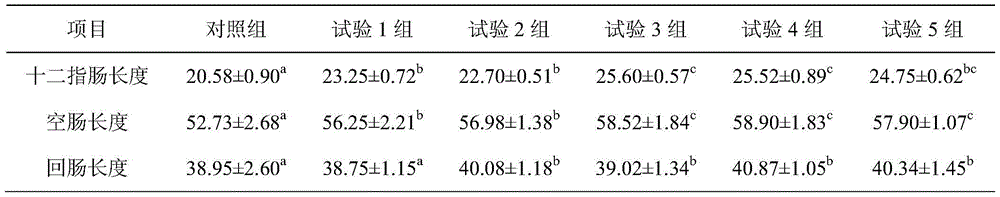

[0029]In order to verify the application effect of sustained-release butyric acid in broiler chicken production, the zeolite butyric acid powder prepared according to the method in Example 2 was subjected to a broiler chicken feeding test. 288 AA broilers of the same breed were randomly divided into 6 groups, with 6 repetitions in each group and 8 chickens in each repetition: the first group was the control group, fed the basal diet; the second group added 0.05 % sodium butyrate, the third group added 1% clinoptilolite on the basis of the basic diet, and the fourth to sixth groups added 0.5%, 1%, and 2% zeolite butyric acid powder on the basis of the basic diet , the test period is 21d. The chicken coop was thoroughly cleaned and disinfected before the experiment. Feeds were fed regularly, twice a day. During the test, the mental state of the flock was observed, and the daily feed intake of the test chicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com