Rear-mounted stress-type glaucoma drainage valve

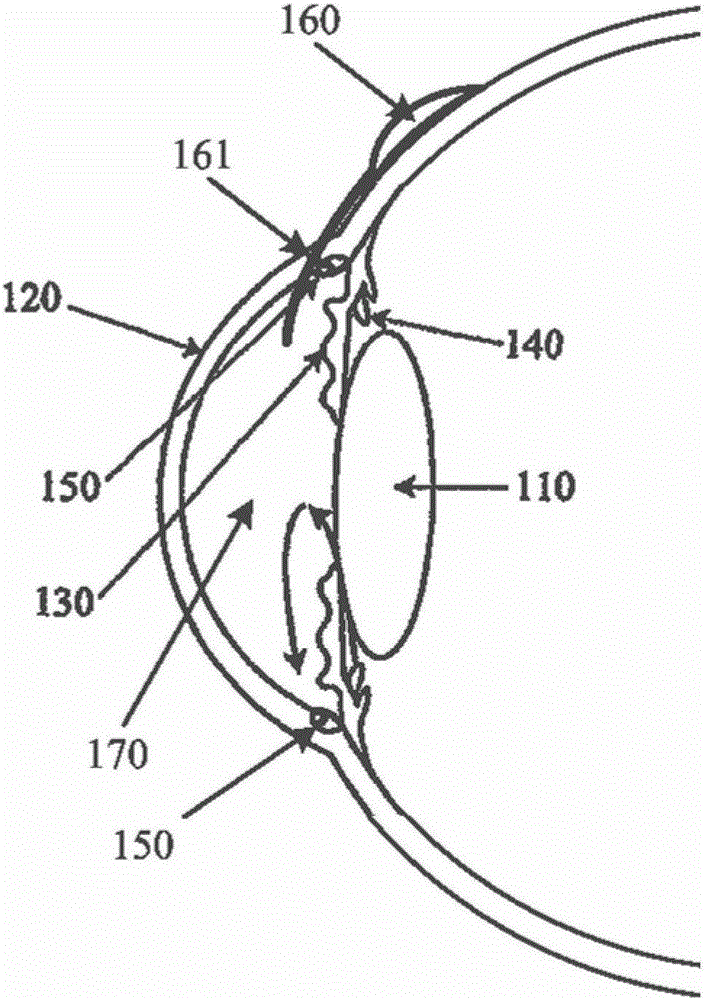

A posterior type, glaucoma technology, applied in the field of ophthalmic surgery, can solve the problems of high cost and complicated structure of the drainage device, and achieve the effect of not easy to block, control the damage of optic nerve and optic function, and easy to insert and replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

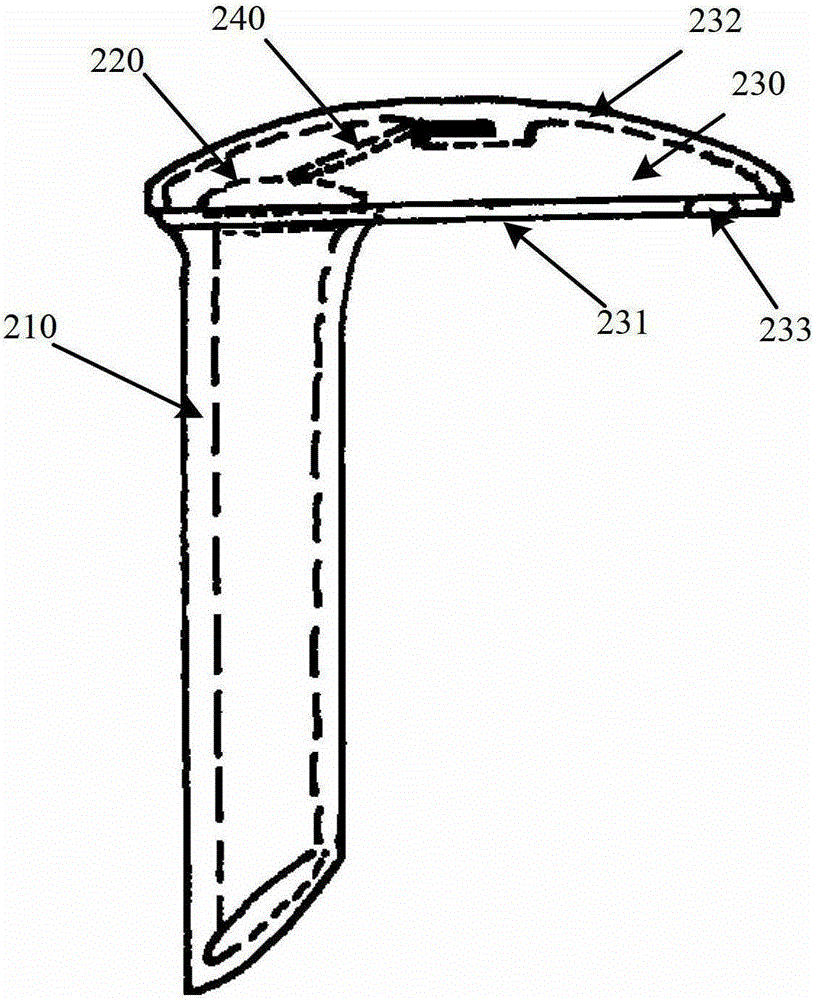

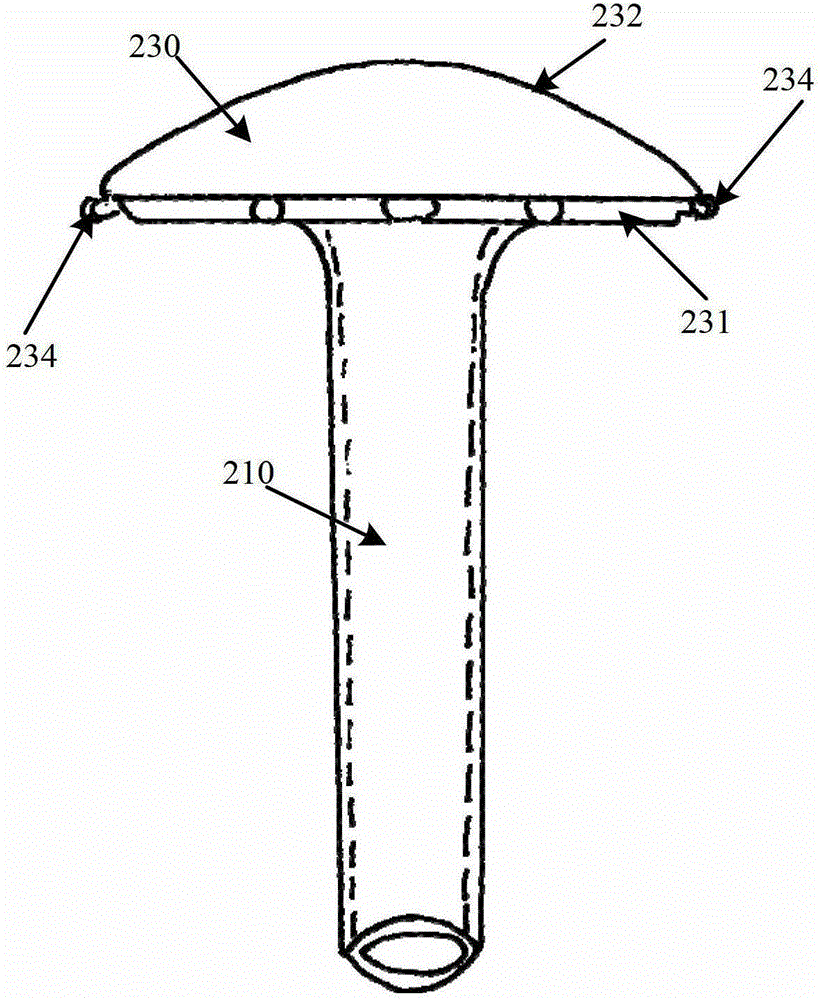

[0041] An embodiment of the post-type stress glaucoma drainage valve of the present invention is as follows Figure 2-4 As shown in the figure, it includes a hollow drainage pipe 210 and a valve cover 220 for controlling the opening and closing of the drainage pipe, and is characterized in that:

[0042] The drainage pipe 210 is embedded in an openable casing 230, the casing 230 is composed of a drainage plate 231 and a casing cover 232. The guide groove 235 on the edge of the plate 231, see Figure 8 with Figure 9 .

[0043] The outlet end of the drainage pipe 210 is embedded in the drainage plate 231 , and the inlet end of the drainage pipe 210 is perpendicular to the lower surface of the drainage plate 231 and protrudes downward from the lower surface of the drainage plate 231 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com