Pressed powder and production process thereof

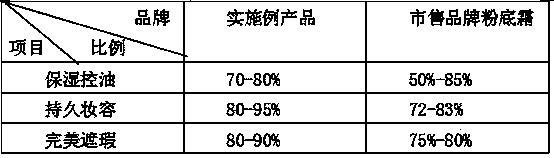

A production process and technology of powder cakes, which are applied in the directions of body powder, cosmetics, preparations for skin care, etc., can solve problems such as inability to ensure hygiene, difficulty in protecting skin care and curing skin problems, and decrease in skin moisture content. Reduces the production of cyclobutane pyrimidine dimers, excellent antioxidant stability, and reduces fine lines and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

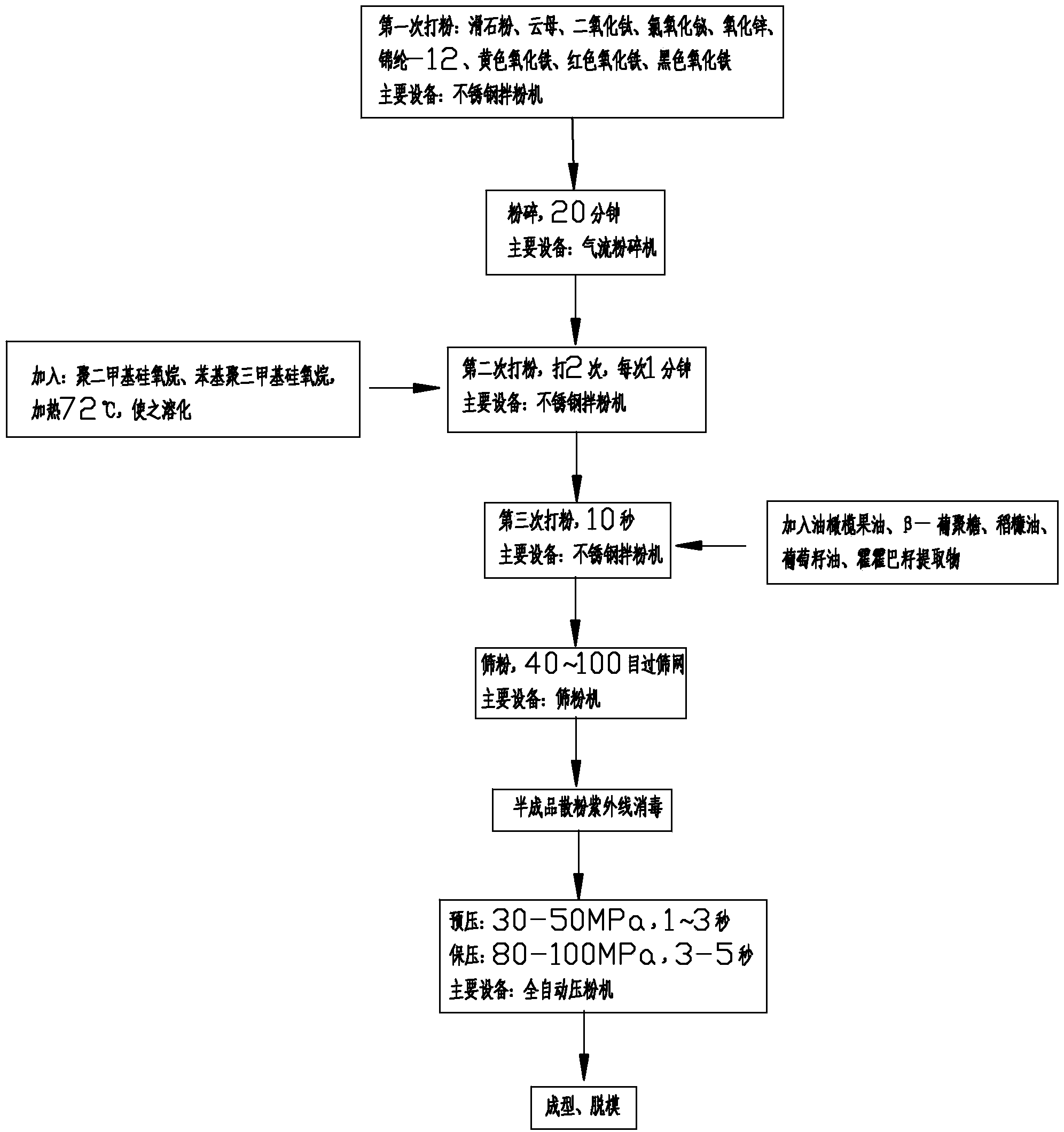

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 of powder cake: a kind of powder cake, including the preparation of uniformly mixed briquetting of the following ingredients: mass percentage selection, talcum powder is 20%, mica is 30%, bismuth oxychloride is 5%, zinc oxide is 8%, Nylon-12 is 8.4%, polydimethylsiloxane is 8%, phenyl polytrimethicone is 2.5%, titanium dioxide is 10%, yellow iron oxide is 1%, red iron oxide is 0.8%, Black Iron Oxide 0.8%, Rice Bran Oil 1%, Beta-Glucan 1.5%, Olive Fruit Oil 1%, Grape Seed Oil 1%, Jojoba Seed Extract 1%.

Embodiment 2

[0044] Embodiment 2 of powder cake: a kind of powder cake is prepared by uniformly mixing and briquetting the following ingredients: mass percentage selection, talcum powder is 30%, mica is 20%, bismuth oxychloride is 8%, zinc oxide is 5%, Nylon-12 is 12%, polydimethylsiloxane is 4%, phenyl polytrimethicone is 1.6%, titanium dioxide is 5%, yellow iron oxide is 5%, red iron oxide is 0.2%, Black Iron Oxide 0.2%, Rice Bran Oil 2%, Beta-Glucan 1%, Olive Fruit Oil 2%, Grape Seed Oil 2%, Jojoba Seed Extract 2%.

Embodiment 3

[0045] Embodiment 3 of powder cake: a kind of powder cake is prepared by uniformly mixing and briquetting the following ingredients: the mass percentage is selected, talcum powder is 40%, mica is 10%, bismuth oxychloride is 12%, zinc oxide is 2%, Nylon-12 is 6%, polydimethylsiloxane is 12%, phenyl polytrimethicone is 0.7%, titanium dioxide is 2%, yellow iron oxide is 2%, red iron oxide is 0.4%, Black Iron Oxide 0.4%, Rice Bran Oil 3%, Beta-Glucan 0.5%, Olive Fruit Oil 3%, Grape Seed Oil 3%, Jojoba Seed Extract 3%.

[0046] In the present invention, the yellow iron oxide is CI77492; the red iron oxide is CI77491; and the black iron oxide is CI77499.

[0047] By adopting the above-mentioned technical scheme, natural plant ingredients such as rice bran oil, β-glucan, olive fruit oil, grape seed oil, and jojoba seed extract are added to the traditional formula of the pressed powder.

[0048] Rice bran oil is rich in vitamin E (tocopherol), ferulic acid ester (oryzanol), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com