MIL-53 needle tube-type solid phase microextraction probe and preparation method thereof

A MIL-53, needle tube technology, applied in chemical instruments and methods, material separation, instruments, etc., can solve the problems of fragile SPME silica matrix probes, poor coating stability, short service life, etc., and achieve thermal stability Good resistance and chemical stability, solvent washing resistance, easy material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

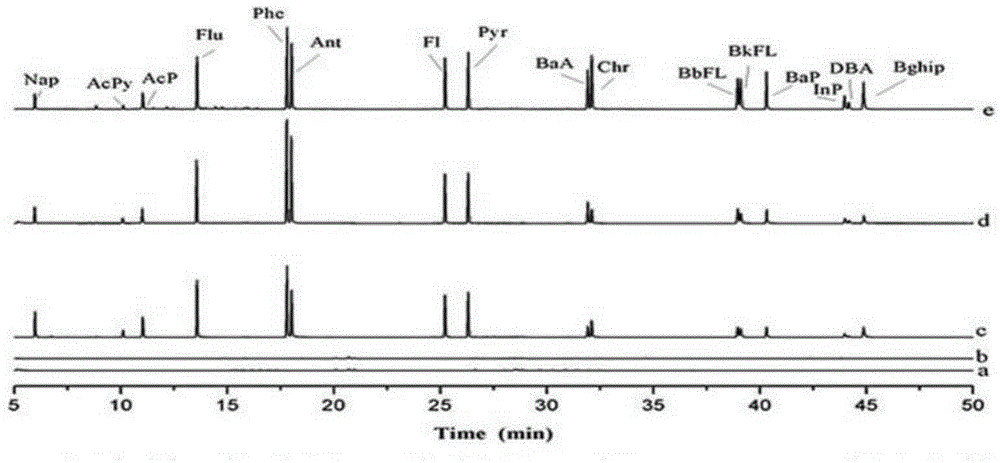

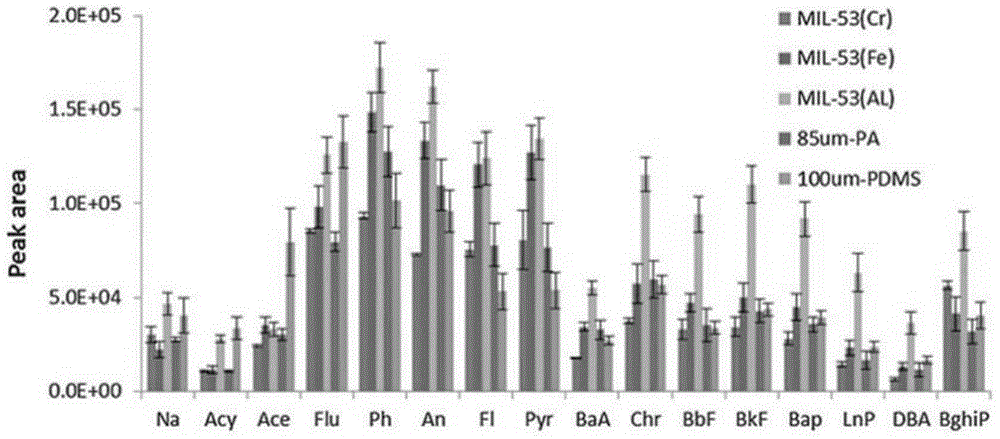

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

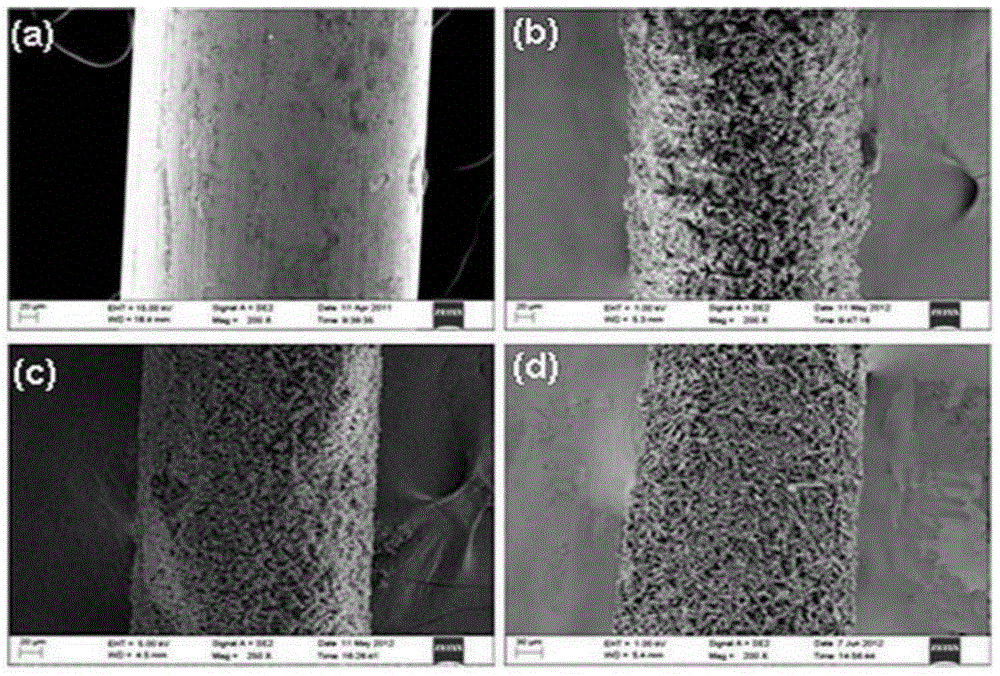

[0022] The MIL-53 needle-tube solid-phase microextraction probe of the present invention includes a probe substrate and a coating material, and is characterized in that the substrate of the probe is made of tubular stainless steel, and the coating material is a porous metal organic framework material. A kind of solid-phase microextraction probe based on MIL-53 (Al) coating material is prepared by following steps:

[0023] ① Mix aluminum nitrate, terephthalic acid and deionized water evenly according to the molar ratio of 1:0.5:80, then put them into a 100ml polytetrafluoroethylene reactor and react at 220°C for 3 days. After cooling, filter and wash with distilled water four times, then reheat to 280 ° C for 1 hour to remove unreacted terephthalic acid, and prepare MIL-53 (Al) powder for later use;

[0024] ②Cut off 5 μl of gas-phase micro-sampling nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com