Recycling method of solid waste

A technology of solid waste and grinding material, which is applied in the field of reuse of MnZn soft magnetic waste, can solve the problems of difficulty in obtaining good benefits and inefficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

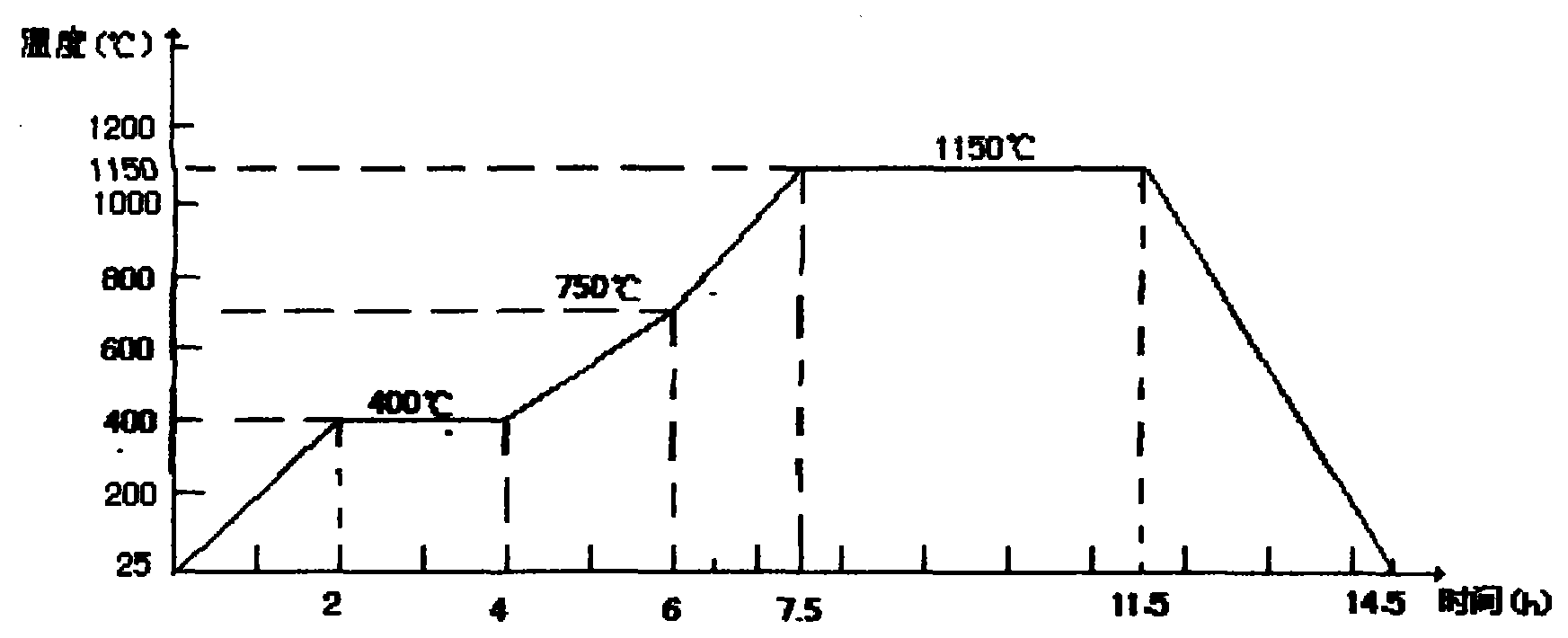

[0025] According to the invention figure 1 The shown sintering temperature curves embody the present invention, but the present invention is not limited to these examples.

[0026] (1) Grinding material pulping: According to the ratio of material: water = 1:1, the grinding material is dispersed in a ball mill to make a diluted slurry.

[0027] (2) Screening: Use a 40-mesh screen to remove impurities in the abrasive slurry.

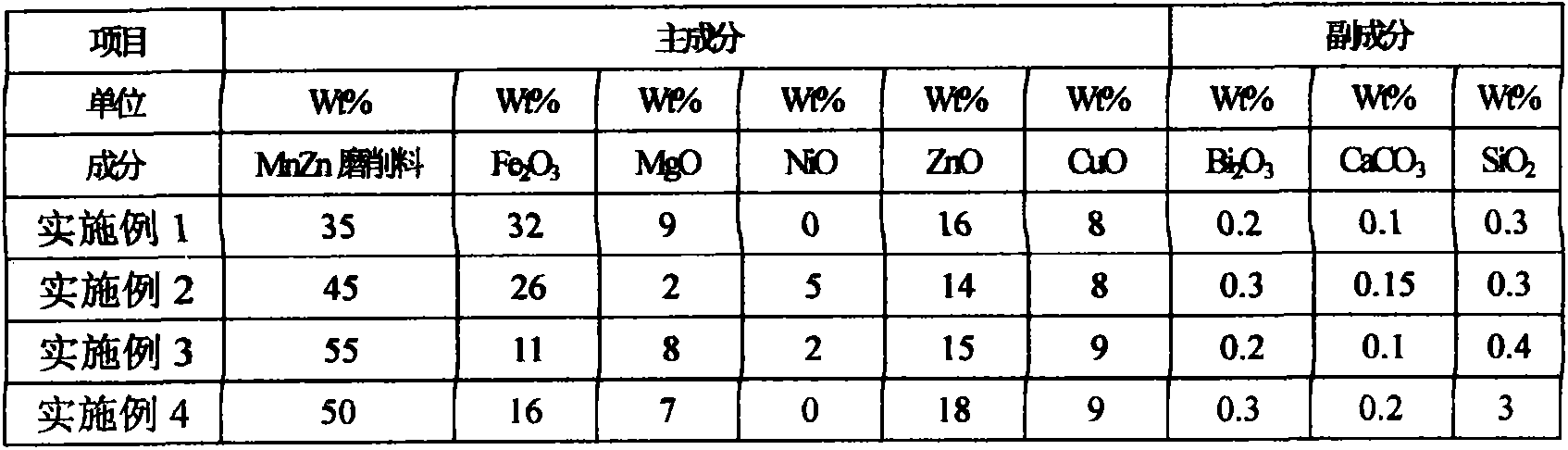

[0028] (3) Ingredients: According to the solid content of the grinding slurry, according to the ratio of the embodiment in Table 1, add other main components: nickelous oxide, zinc oxide, copper oxide, magnesium oxide, ferric oxide, etc., or add at the same time Subcomponents such as bismuth oxide, calcium carbonate, and silicon dioxide.

[0029] (4) Ball mill: Mix the materials evenly with a ball mill.

[0030] (5) Circular sand mill: Circular sand mill for 1 to 6 hours, and the particle size of the slurry is controlled at 0.9 to 1.5 μm.

[0031] (6) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com