Device and method for four-tower dehydration and heavy hydrocarbon removal of natural gas

A natural gas and heavy hydrocarbon removal technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of long-term normal and stable operation of unfavorable devices, discontinuous operation of heating furnace, frequent ignition and shutdown of furnace, etc., to improve regeneration effect, simplification of operation, and effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

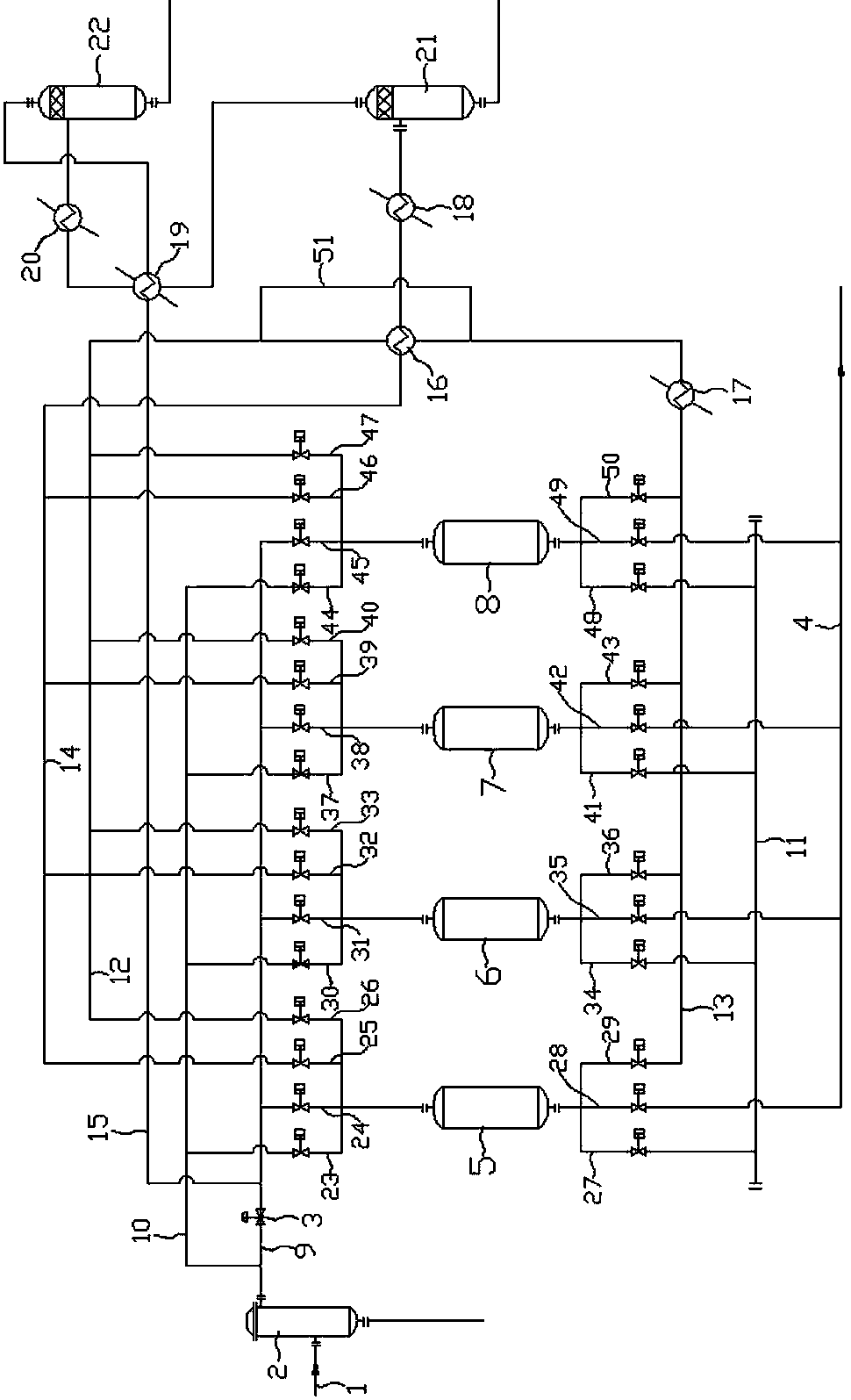

[0045] figure 1 It is a schematic diagram of the structure of the present invention, and this embodiment takes 6 hours of adsorption drying time as an example.

[0046] The device of this embodiment is shown in the figure.

[0047] The device comprises an inlet pipe 1, a coalescing filter 2 connected to the inlet pipe 1, a throttle valve 3, an air outlet pipe 4, a first fixed bed adsorption tower 5, a second fixed bed adsorption tower 6, and a third fixed bed adsorption tower 7. The fourth fixed bed adsorption tower 8, the first pipeline 9, the second pipeline 10, the third pipeline 11, the fourth pipeline 12, the fifth pipeline 13, the sixth pipeline 14, the seventh pipeline 15, the first heat exchanger 16. Second heat exchanger 17, third heat exchanger 18, fourth heat exchanger 19, fifth heat exchanger 20, first gas-liquid separator 21, second gas-liquid separator 22, tower one first Feed pipe 23, tower-second feed pipe 24, tower-third feed pipe 25, tower-fourth feed pipe ...

Embodiment 2

[0068] The first wet natural gas passing through the fourth pipeline 12 is heated to 200° C. after passing through the first heat exchanger 16 and the second heat exchanger 17 in sequence. The first wet natural gas in the sixth pipeline 14 also contains water and heavy hydrocarbons. The first wet natural gas passes through the first heat exchanger 16 and the third heat exchanger 18, and after being cooled to 25°C, it enters the first gas-liquid In the separator 21, the moisture in the first wet natural gas is removed. The first wet natural gas after dehydration passes through the fourth heat exchanger 19 and the fifth heat exchanger 20, and after being cooled to 5°C, enters the second gas-liquid separator 22 to remove the heavy hydrocarbons therein. Dry natural gas is obtained, and the removed heavy hydrocarbons are discharged.

[0069] Others are the same as in Example 1.

Embodiment 3

[0071] The first wet natural gas passing through the fourth pipeline 12 is heated to 300° C. after passing through the first heat exchanger 16 and the second heat exchanger 17 in sequence. The first wet natural gas in the sixth pipeline 14 also contains water and heavy hydrocarbons. After being cooled to 35°C through the first heat exchanger 16 and the third heat exchanger 18, the first wet natural gas enters the first gas-liquid In the separator 21, the moisture in the first wet natural gas is removed. The first wet natural gas after dehydration passes through the fourth heat exchanger 19 and the fifth heat exchanger 20, and after being cooled to 15°C, enters the second gas-liquid separator 22 to remove the heavy hydrocarbons therein. Dry natural gas is obtained, and the removed heavy hydrocarbons are discharged.

[0072] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com