Self-adaptive common-light-path grating interferometer and realizing method thereof

A technology of grating interference and common optical path, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of not adopting a complete common optical path interferometer design and the inability to eliminate the influence of optical path, and achieve the elimination of motion errors, high precision and resolution rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

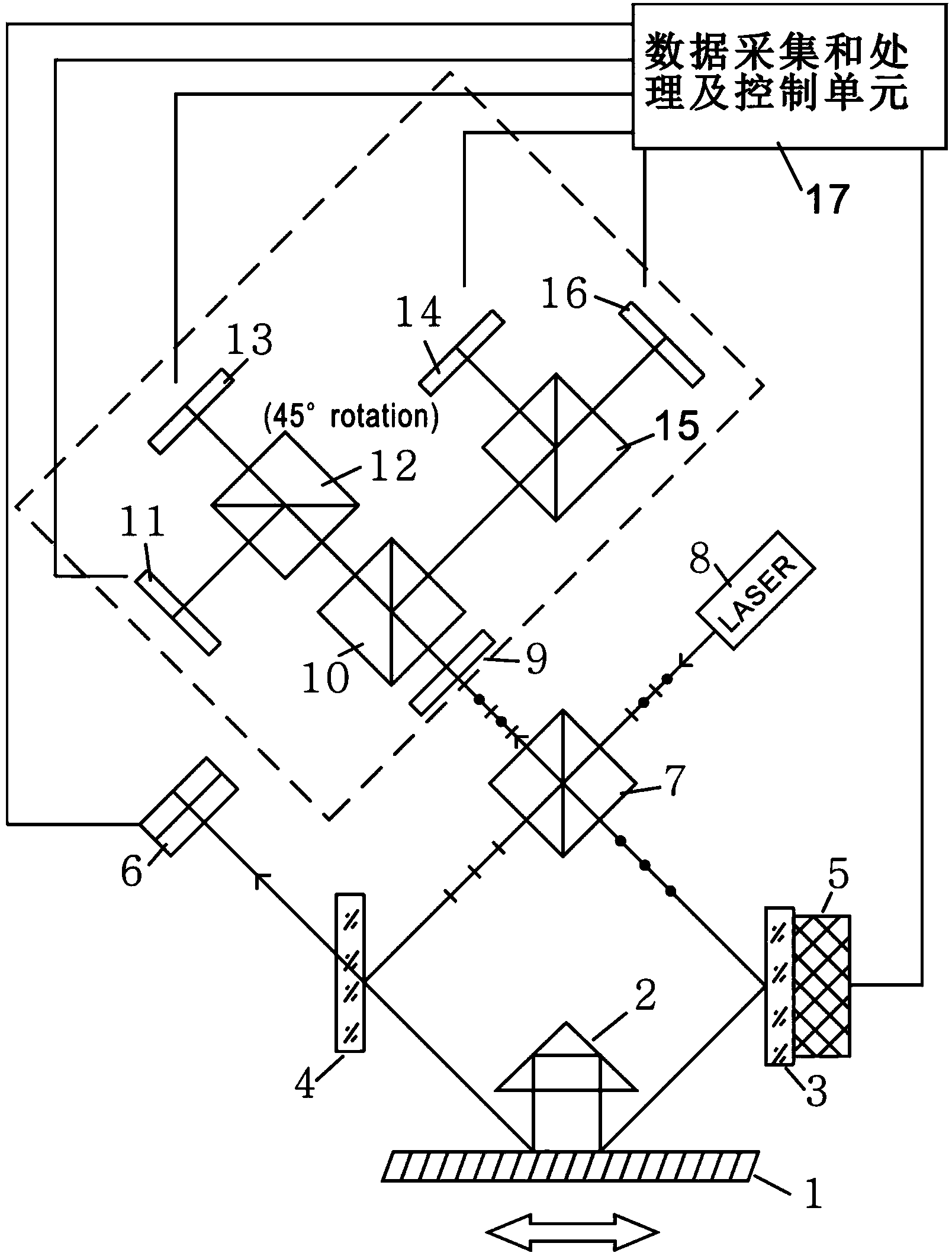

[0032] 1. Embodiment 1. Such as figure 1 .

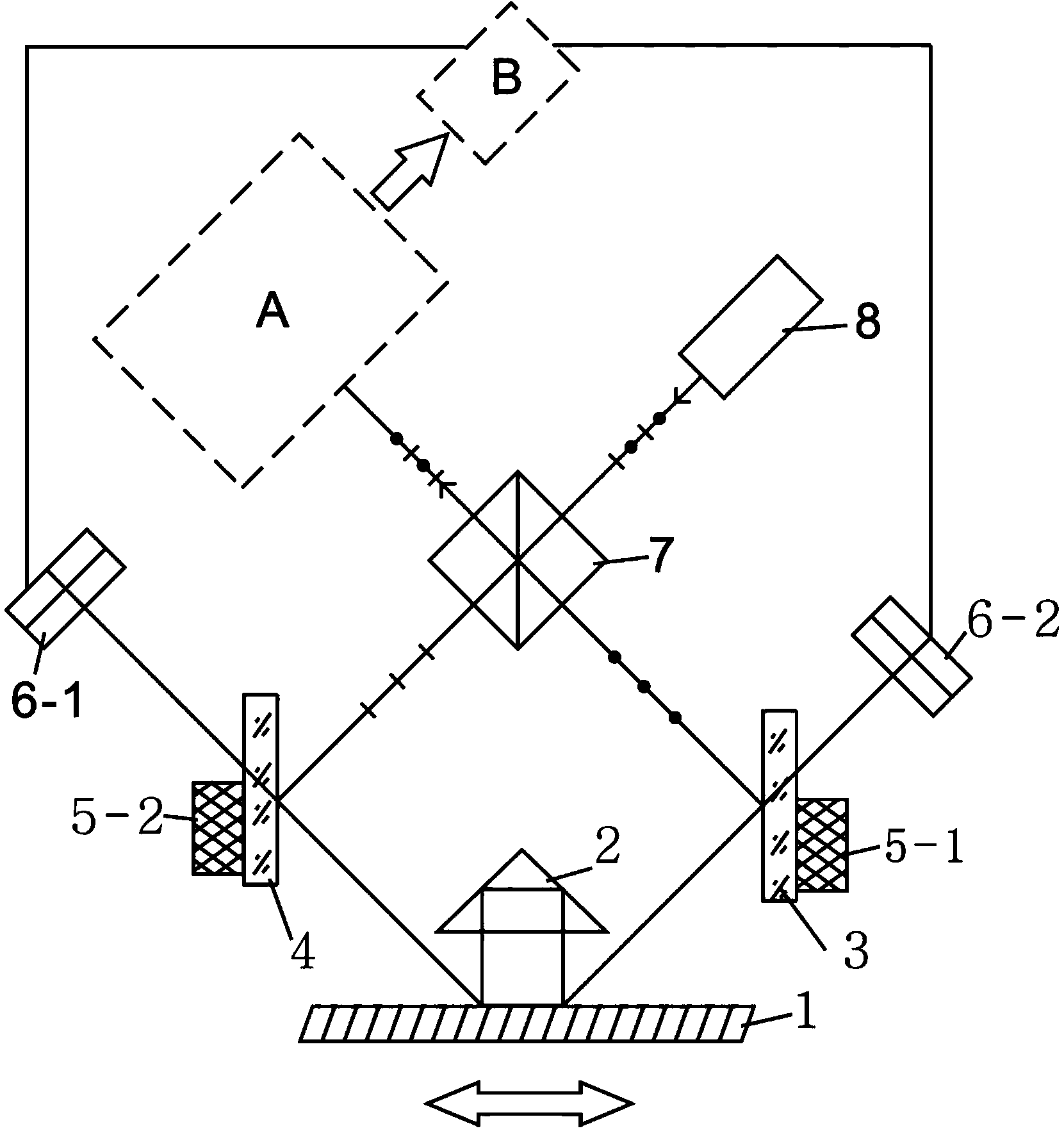

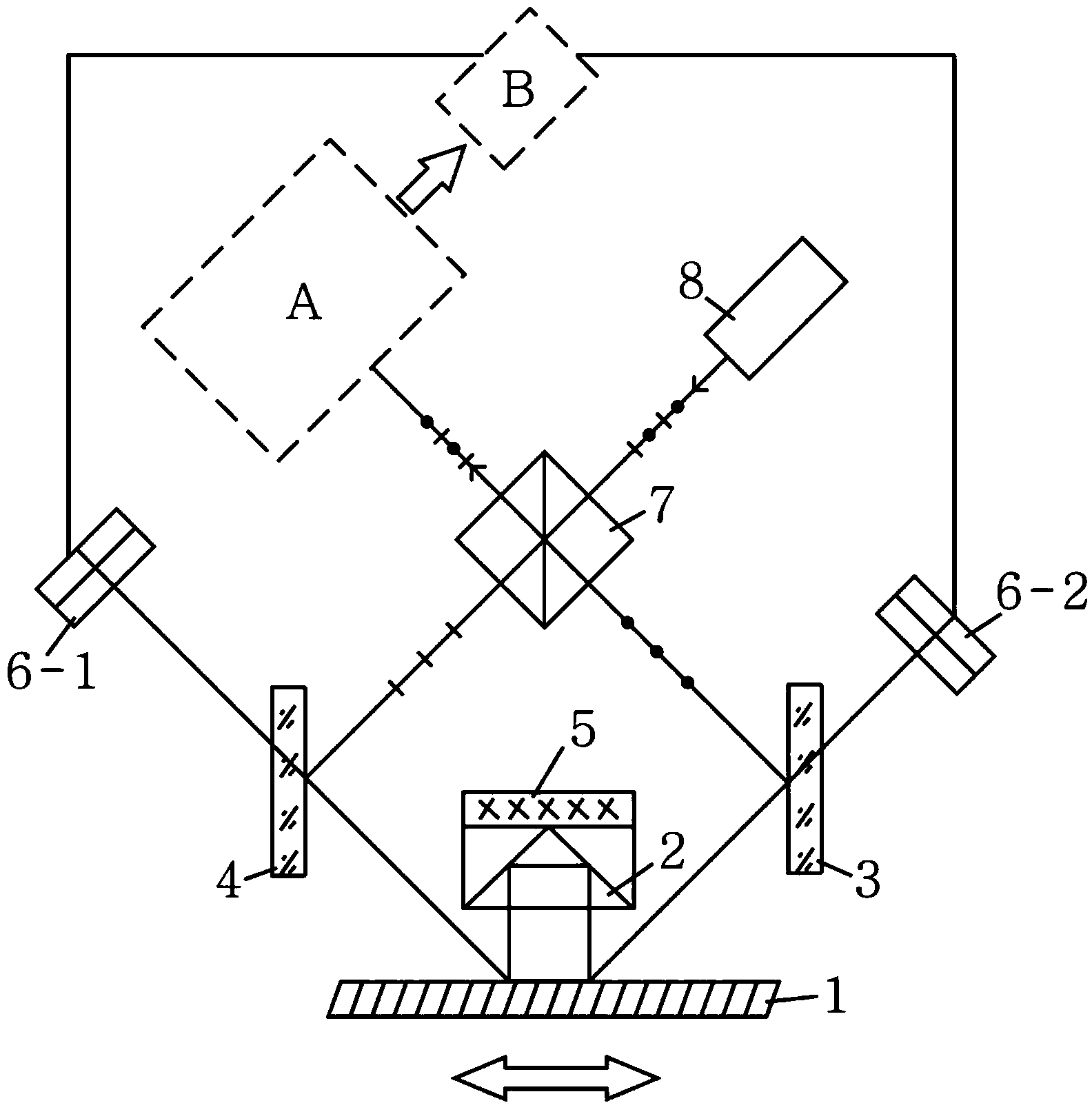

[0033] The laser 8 emits linearly polarized light, which is divided into P light and S light by the first polarizing beam splitter 7, and enters the diffraction grating 1 through the mirror 3 and the mirror 4 respectively, and is diffracted by the diffraction grating 1 (set as ±1-order light The direction of the two diffracted lights of ) is perpendicular to the diffraction grating 1, and after being reflected by the corner cube prism 2, the P light and the S light respectively enter the respective optical paths of the other party (S light and P light), forming a complete common optical path, and then pass through the first polarization Beam splitter 7 emerges as orthogonal linearly polarized light, which enters the dotted line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com