On-line monitoring method for heat rate of steam turbine on basis of soft measurement technology

A technology of steam turbine and heat consumption rate, applied in the direction of measuring heat, calorimeter, measuring device, etc., can solve problems such as exacerbating the deviation of flow measurement value and actual value, inaccurate flow measurement on site, application limitation, etc., to achieve stable heat consumption rate monitoring results, overcoming heat consumption rate monitoring methods, overcoming technical deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

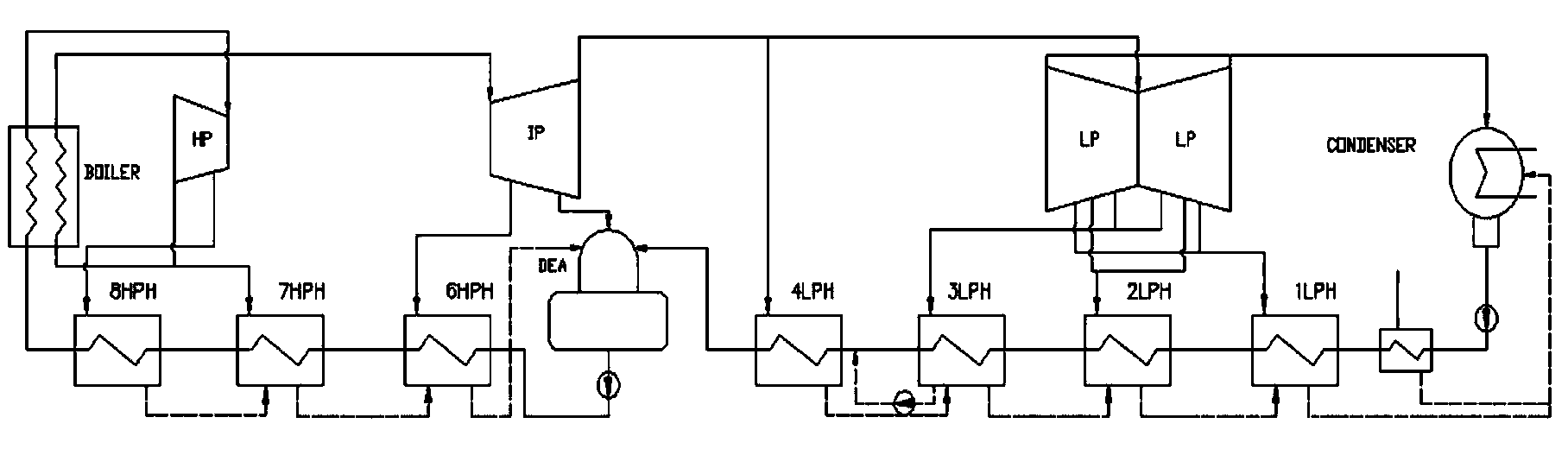

[0103] The present invention is applied to a 660MW primary reheating thermal power generation unit, the steam parameter is 16.7MPa / 560°C / 560°C, and the principle thermal system structure of the steam turbine reheating system is as follows figure 2 .

[0104] According to the specific steps of this method:

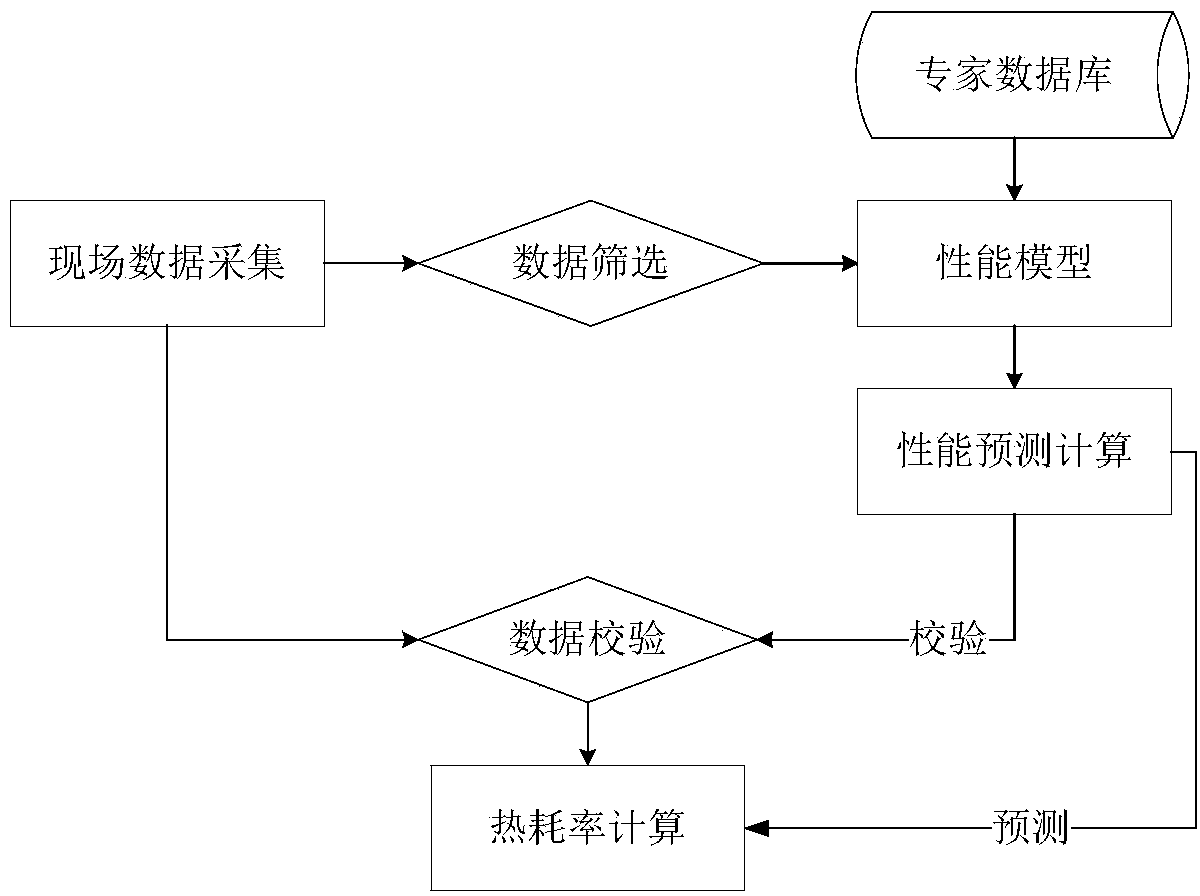

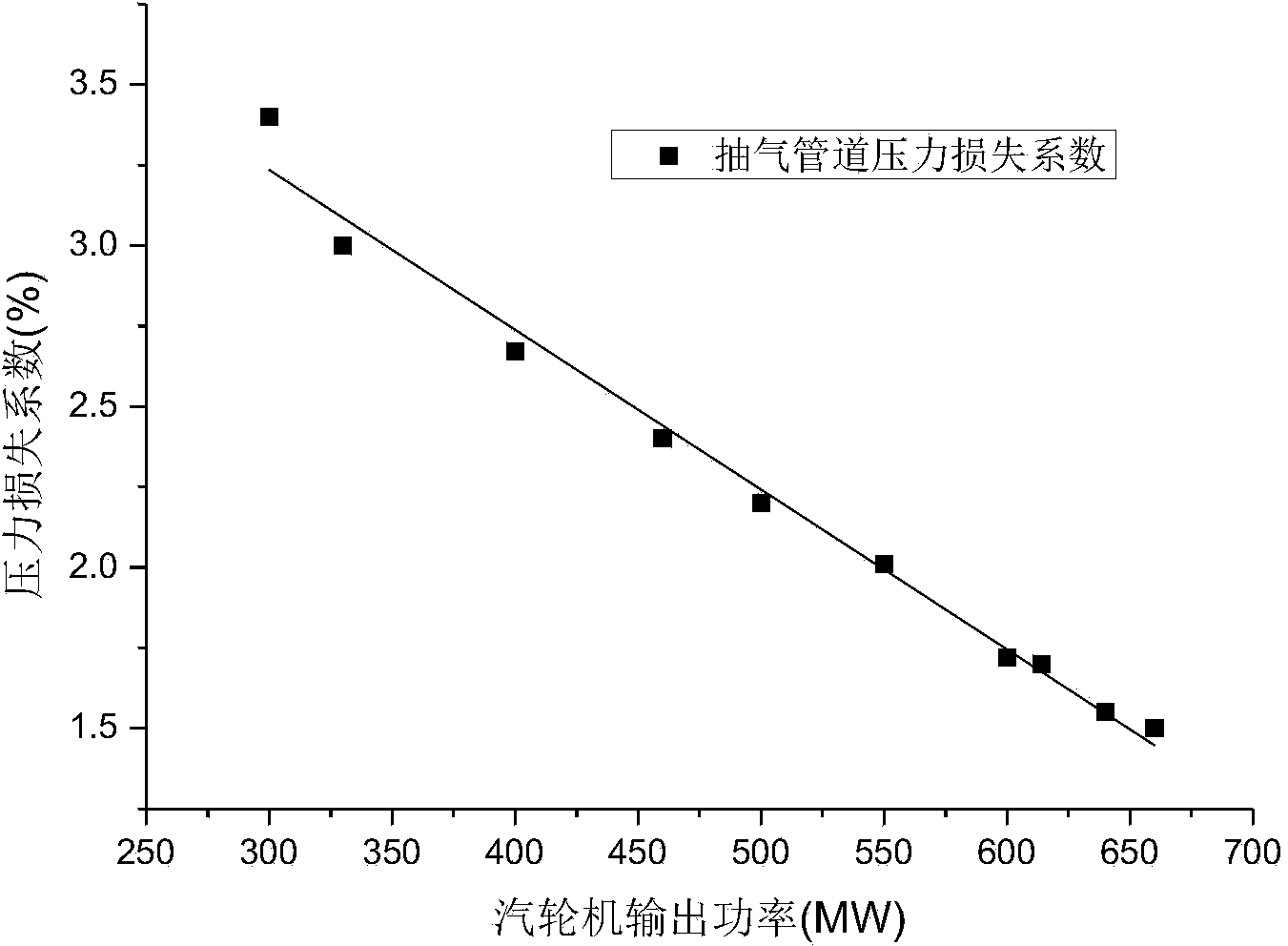

[0105] According to the thermodynamic principle diagram of the steam turbine recuperation system, the historical operation data of the steam turbine recuperation system, and the thermal performance test conclusions of the steam turbine recuperation system, determine the pressure level inlet and outlet pressure ratio, the suction pipe pressure loss coefficient, the heater Expressions for end differential and low-pressure cylinder efficiency. according to figure 2 , and formula (2) to formula (22), and the undetermined coefficient function in the expert knowledge base, establish the performance prediction model of the steam turbine recuperator system, and select the undet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com