Method of fracturing using ultra lightweight proppant suspensions and gaseous streams

A proppant and gaseous fluid technology, used in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve problems such as being unsuitable for generating single-layer fractures, minimize conductivity loss, reduce device requirements, and enhance fluids The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

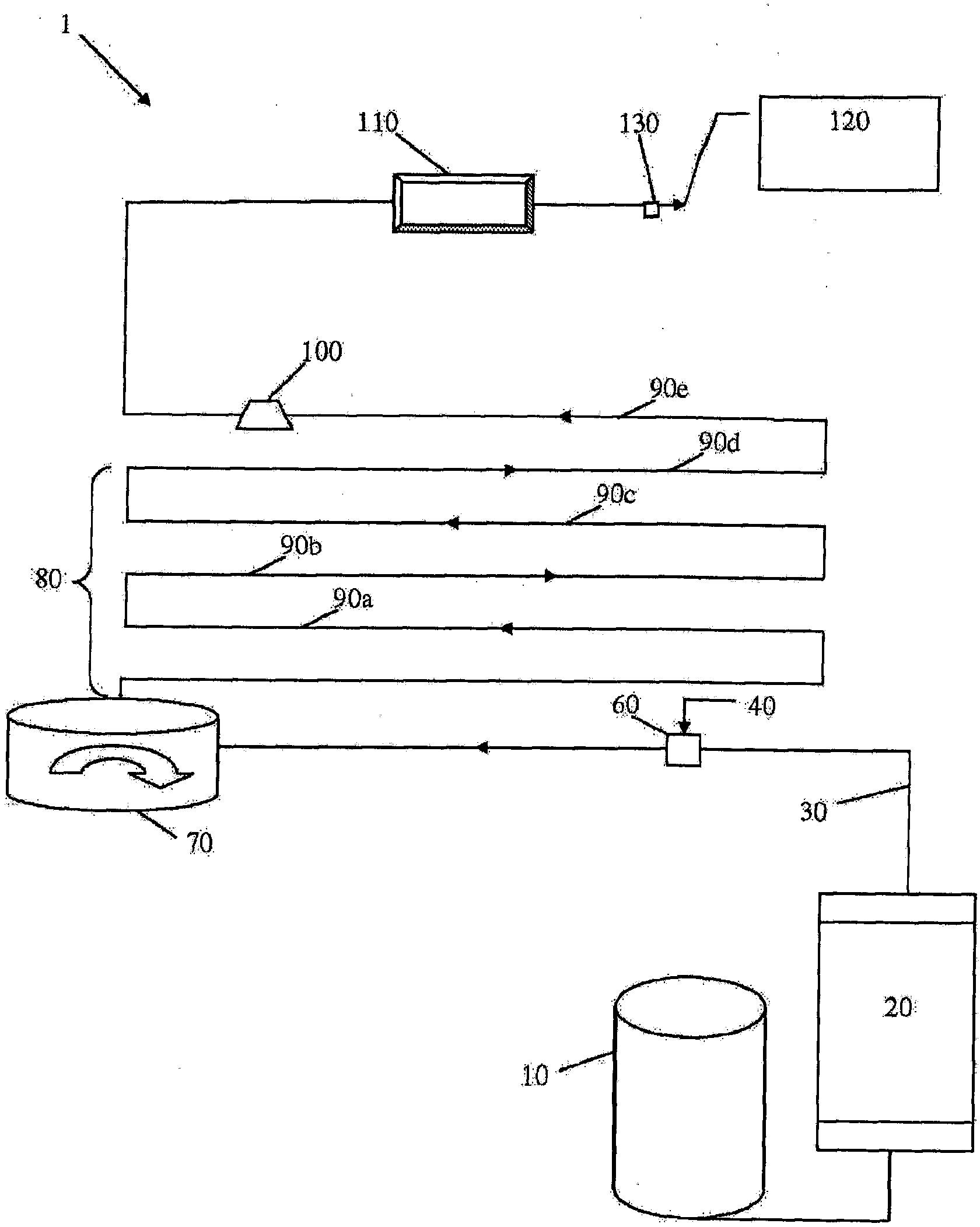

[0055] A stable foam of 95 quality was prepared by adding a viscosifier to the mixing device 10 of the foam flow circuit 1, which circuit further included an aqueous carrier device. The tackifier is added to the mixing device during mixing. The amount of tackifier and added to the mixing device 10 is C 18 Trimethylammonium Chloride [3.5 gal / thousand (gpt)] and 50 / 50 C 18 Blend of trimethylquat ammonium chloride and sodium xylene sulfonate (10.0 gpt). Fluid is then introduced into triplex Cat pump 20 and pumped through mass flow meter 30 . Nitrogen gas 40 is forced through a mass flow meter and into a foam generator 60 . The amount of nitrogen in the froth introduced into the froth flow loop was approximately 95% by volume.

[0056]On leaving the foam generator, the foam enters 1000 feet of coiled 316SS pipe immersed in an oil bath 70 for approximately 25-30 minutes. The oil bath temperature is about 100°F. The foam then enters the capillary viscometer 80 after passing th...

Embodiment 2

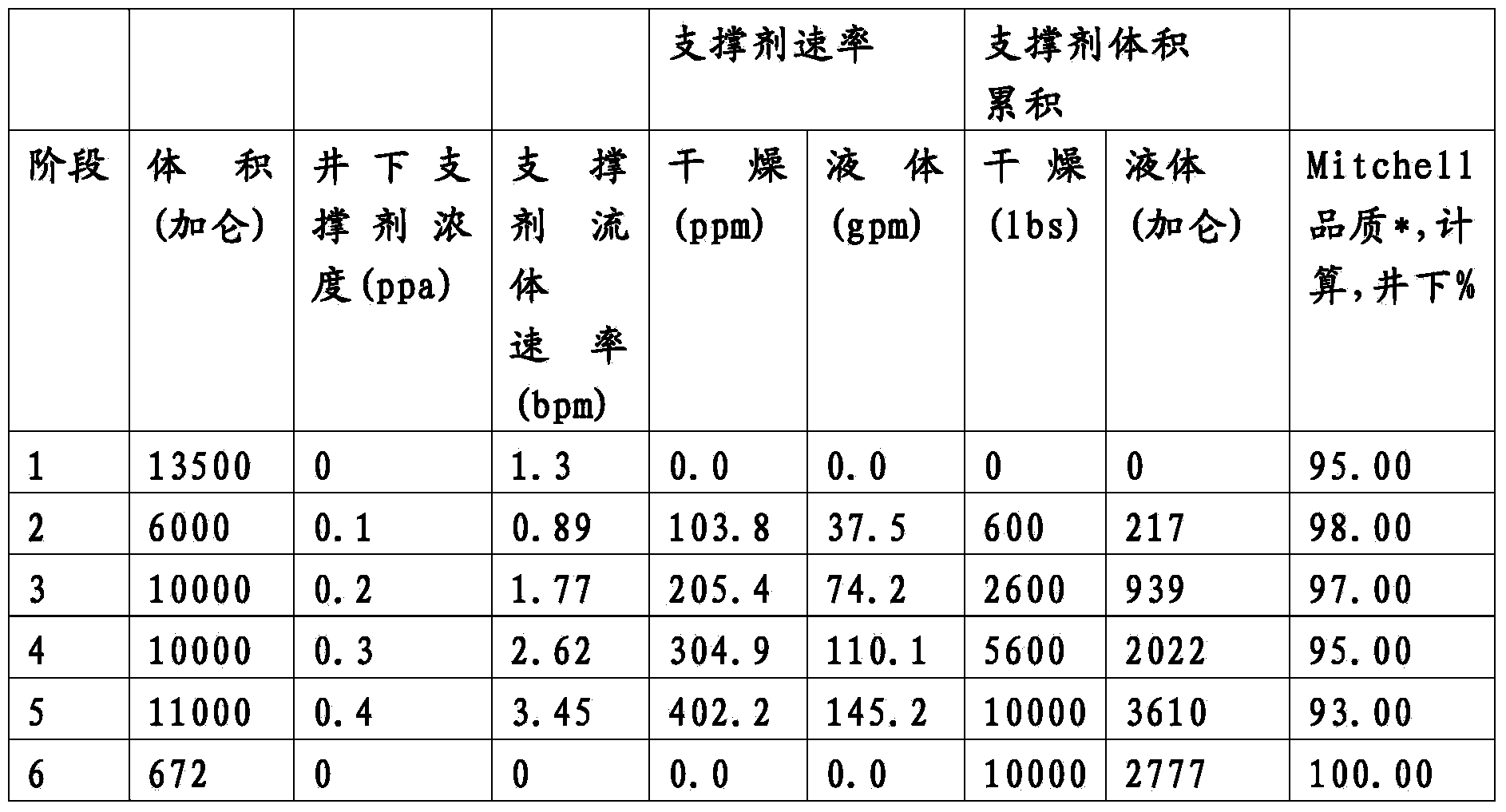

[0058] A fracturing treatment is proposed for the Niobrara Chalk formation with a depth to the middle perforation of 1034 feet; bottom hole static temperature is about 73°F, bottom hole fracture pressure is about 724 psi; surface treatment pressure (maximum) is about 751 psi; and the fracture gradient is about 0.70 psi / ft. The desired result is the distribution of a partial monolayer of proppant upon fracture closure. It has been determined that the frac treatment will require approximately 10,000 pounds of ultra-light weight proppant. The ULW proppant selected was LiteProp 108, a 14 / 40 mesh thermoplastic ultra-lightweight proppant with an apparent specific gravity of approximately 1.05, a product of BJ Services Company. The evaluated liquid proppant concentration was estimated to add approximately 4 pounds of proppant per gallon of liquid (ppa). This represents the estimated concentration of proppant required to accommodate the flow rate of the pump. Additionally, the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com