Method for achieving bisphenol A steam extraction unit vacuum through steam jetting and liquid ring vacuum pump

A technology of liquid ring vacuum pump and jet pump, which is applied in the vacuum field of bisphenol A stripping unit, which can solve the problems of Roots seizure, inability to entrain liquid, and failure of Roots pump to work normally, so as to achieve simple operation and ensure long-term operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

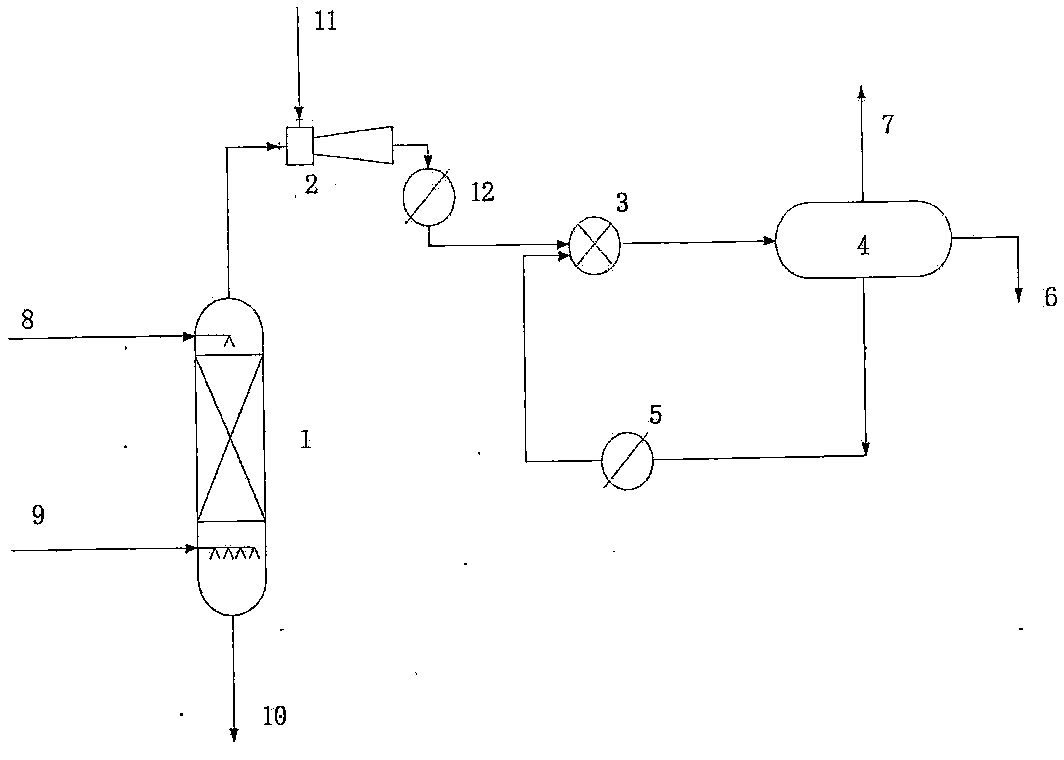

[0012] A method for realizing the vacuum of the bisphenol A stripping unit by combining steam injection + liquid ring vacuum pump, sending the bisphenol A molten liquid containing a small amount of phenol into the stripping tower 1 through the feed line 8, and passing the steam at the bottom of the stripping tower Line 9 feeds stripping steam into stripping tower 1, and under vacuum conditions, phenol is vaporized and comes out from the top of stripping tower 1 and enters steam jet pump 2, and steam jet pump forms vacuum under the injection effect of jet steam 11, from The gaseous phenol and jet steam of the steam jet pump 2 are cooled by the cooler 12 and sent to the liquid ring vacuum pump 3. The working fluid of the liquid ring vacuum pump 3 is the circulating phenol-containing water from the cooler 5, and the phenol-containing water from the liquid ring vacuum pump 3 Water and non-condensable gas are sent into the gas-liquid separation tank 4, and the non-condensable gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com