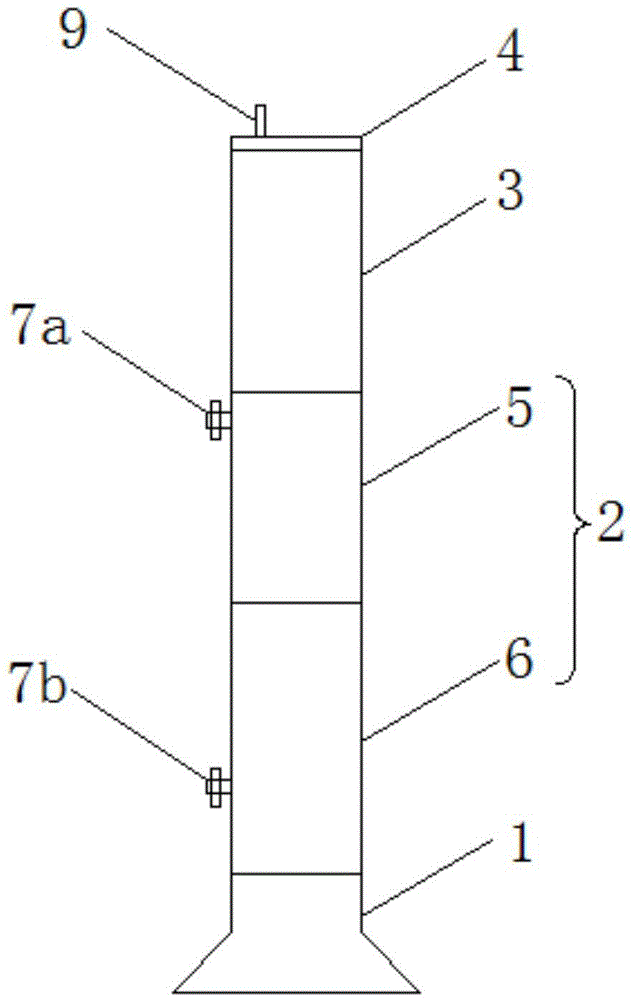

Fine sediment grading device and method

A grading device and fine particle technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problem that the sediment of a certain particle size cannot be directly obtained, the sieve holes of the fine sieve and the filter membrane holes are easily blocked, and cannot Sand sample batch processing and other issues, to achieve the effect of precise control of settling time, easy cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

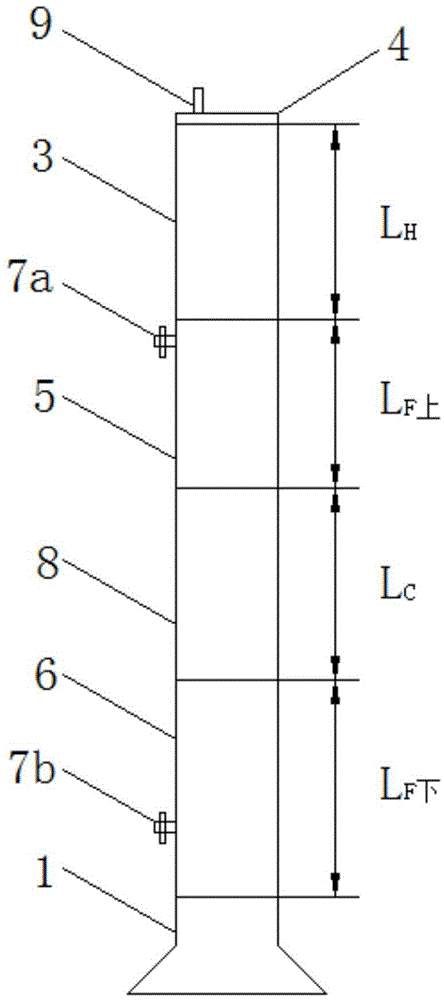

[0072] Taking the sediment in the particle size range of 8-16 μm as an example, the instructions for the use of the sediment particle size classification device are given, and the specific implementation steps are as follows:

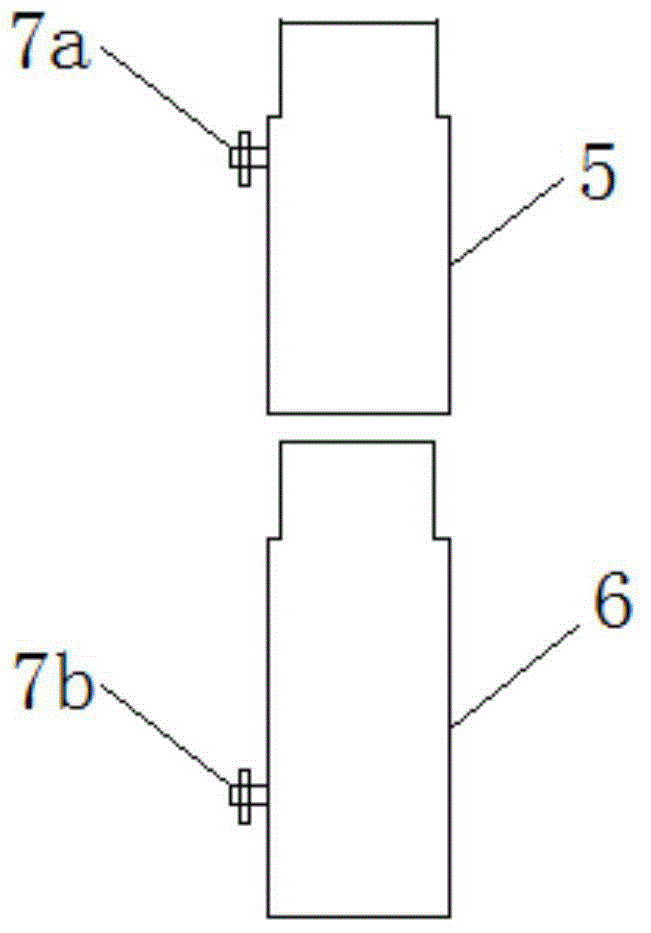

[0073] 1) If there are settling transition barrels, upper barrels and lower barrels with fixed barrel lengths, the effective length of the settling transition barrels is L H =5cm, the effective lengths of the upper and lower cylinders are L respectively F上 = L F下 = 15cm, then the effective length L of the sediment classification cylinder F = 30cm, the closing time t of the upper control valve and the lower control valve of the sediment classification cylinder is obtained from the calculation formula 1 = 14.5min, t 2 =25.4min, if in order to improve efficiency, consider when L F = 3L H At the same time, the upper and lower control valves of the sediment classification cylinder can be closed at the same time, and the effective length L can be added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com