Rutile-phase vanadium dioxide film and preparation method thereof

A vanadium dioxide, rutile phase technology, applied in chemical instruments and methods, solid-state chemical plating, metal material coating technology and other directions, can solve problems such as pure rutile phase vanadium dioxide thin films that have not yet been seen, and achieve strong binding force. , good crystallinity, overcoming the effect of complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

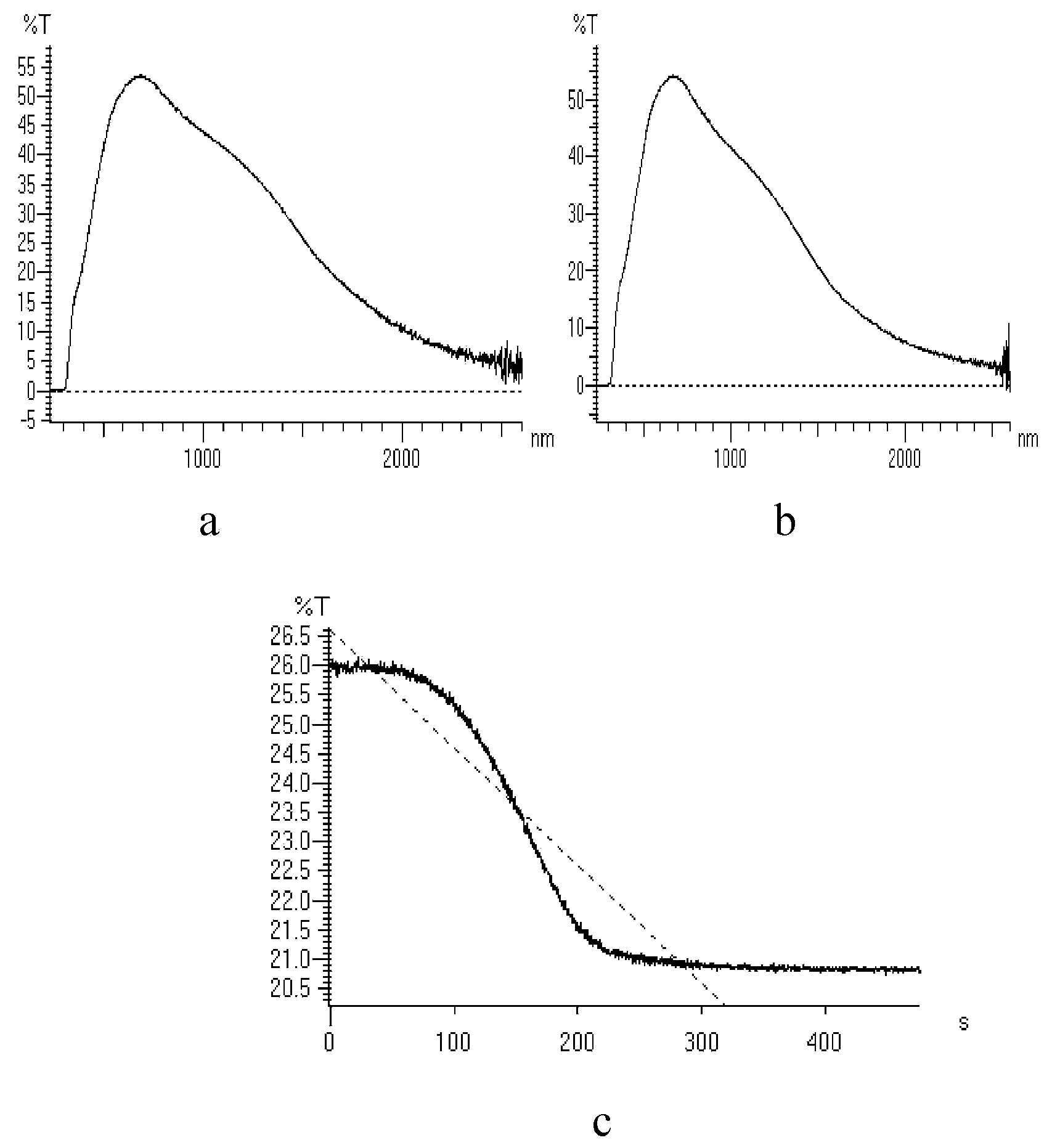

[0048] First prepare 100 ml of alum oxysulfate solution containing 0.001 mol / L, put the cleaned FTO substrate into the reaction kettle, add the above solution and seal it. React at 265°C for 6h and take it out after cooling. Depend on figure 1 It can be seen that the prepared VO 2 The thin film is rutile phase VO with phase change properties 2 , visible light transmittance greater than 50%. The control performance at 2000nm is greater than 5%.

Embodiment 2

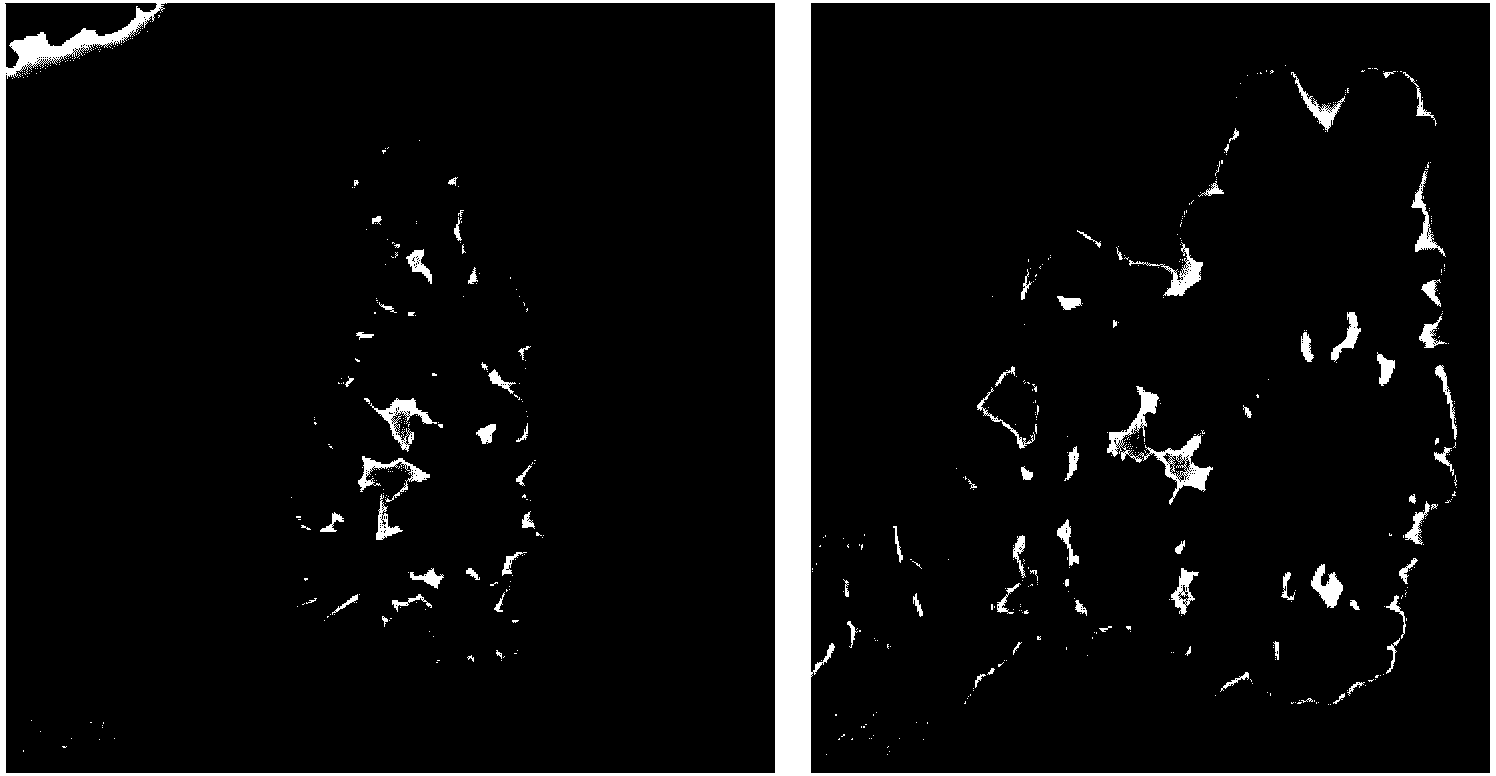

[0050] First prepare 100 ml of alum oxysulfate solution containing 0.005 mol / L, put the cleaned FTO substrate into the reaction kettle, add the above solution and seal it. React at 275°C for 10 hours and take it out after cooling; by figure 2 It can be seen that the powder particles scraped off by the prepared nano-VO2 film can be flower-shaped or needle-shaped. And the prepared VO 2 For the rutile phase.

Embodiment 3

[0052] First prepare 100 ml of vanadyl vanadyl chloride solution containing 0.008 mol / L, and titrate with potassium hydroxide to prepare a suspension. The cloudy solution prepared was then stirred for 30 minutes. Put the cleaned FTO substrate into the reaction kettle, add the above solution and seal it. React at 268°C for 16h and take it out after cooling. Depend on image 3 It can be seen that the prepared VO2 film is a nano-array form with rod-shaped VO 2 exist. At the same time by Figure 5 It can be seen that the film thickness of the prepared nano-vanadium dioxide film is between 300nm and 400nm, and the thickness of the film can be adjusted by adding the amount of vanadium. The prepared VO2 is in the rutile phase. According to calculations, the visible light integral transmittance of the film at high and low temperatures can be adjusted between 40% and 85%, and the phase change control performance can be adjusted between high and low temperature integral differences...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com