Wired geomagnetic guide while drilling and its measurement method

A measurement-while-drilling and guiding instrument technology, applied in construction and other directions, can solve the problems of shallow penetration depth, inability to meet the construction requirements of long-distance and large-depth guided drilling, and short penetration distance, achieving high measurement accuracy and easy popularization and application. Prospect, good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

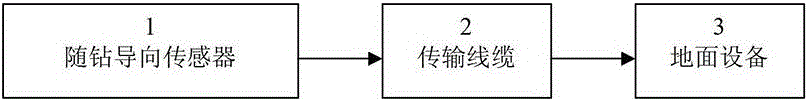

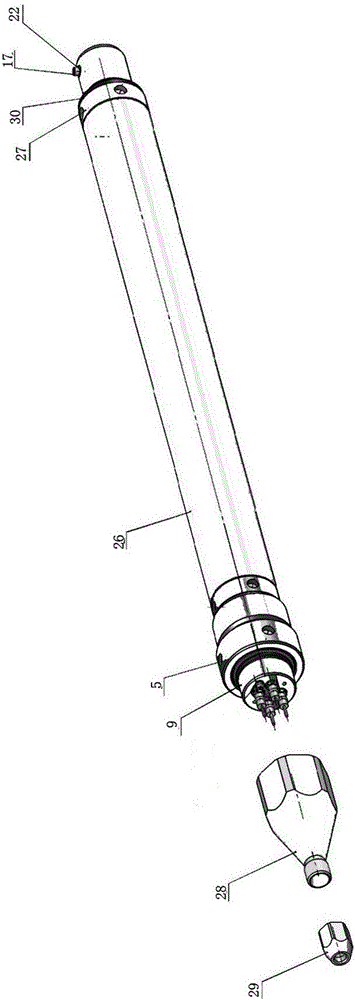

[0041] Embodiment 1: see Figure 1-Figure 7The wired geomagnetic guide while drilling includes two parts: measurement while drilling and ground equipment. The two parts of measurement while drilling and ground equipment communicate through cables. The measurement while drilling part includes the probe of the guide while drilling. The probe of the guide while drilling The upper joint 9 is provided with an inner cavity, and its front end is sealed with a single-core sealing plug 25, and its rear end is connected with a transformer shell, and the cable is connected to the transformer 23 installed in the transformer shell after passing through the upper joint inner cavity from the single-core sealing plug 25; The rear end of the transformer casing is connected with a circuit skeleton 4, and circuit boards 1 and 2 are installed in the connection area between the transformer casing and the circuit skeleton; in the circuit skeleton 4, three directions perpendicular to each other are r...

Embodiment 2

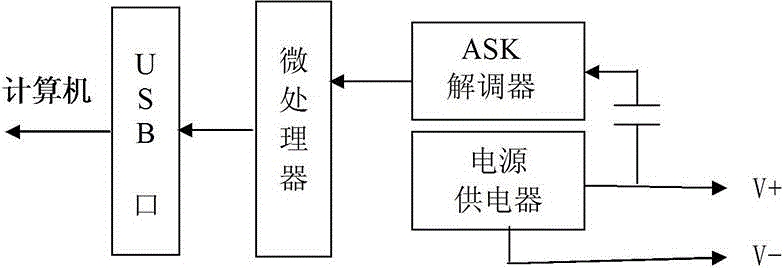

[0042] Example 2: see figure 1 , figure 2 , Figure 8-Figure 11 , The wired geomagnetic guidance-while-drilling measurement method includes two parts: the measurement-while-drilling measurement and the ground equipment, and the communication between the two parts is through a cable, and the communication method is ASK modulation. The measurement while drilling part, that is, the guide probe while drilling, adopts aerospace solid-state inertial navigation technology, and its measurement principle is based on two coordinate systems, namely, the reference coordinate system of the instrument and the measurement coordinate system. The reference coordinate system is established by the gravitational field G of the earth and the geomagnetic field M. The measurement coordinates of the instrument are three sets of sensitive elements installed in the probe of the guide while drilling (each set of sensitive elements contains a magnetic sensor and a gravity accelerometer). Orthogonal mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com