Method for controlling cutting knife of tea-leaf picker based on visual inspection

A technology of visual detection and control methods, applied in the direction of non-electric variable control, position/direction control, control/regulation system, etc., can solve problems affecting tea picking quality and picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1. A tea picking machine cutter control system based on visual detection

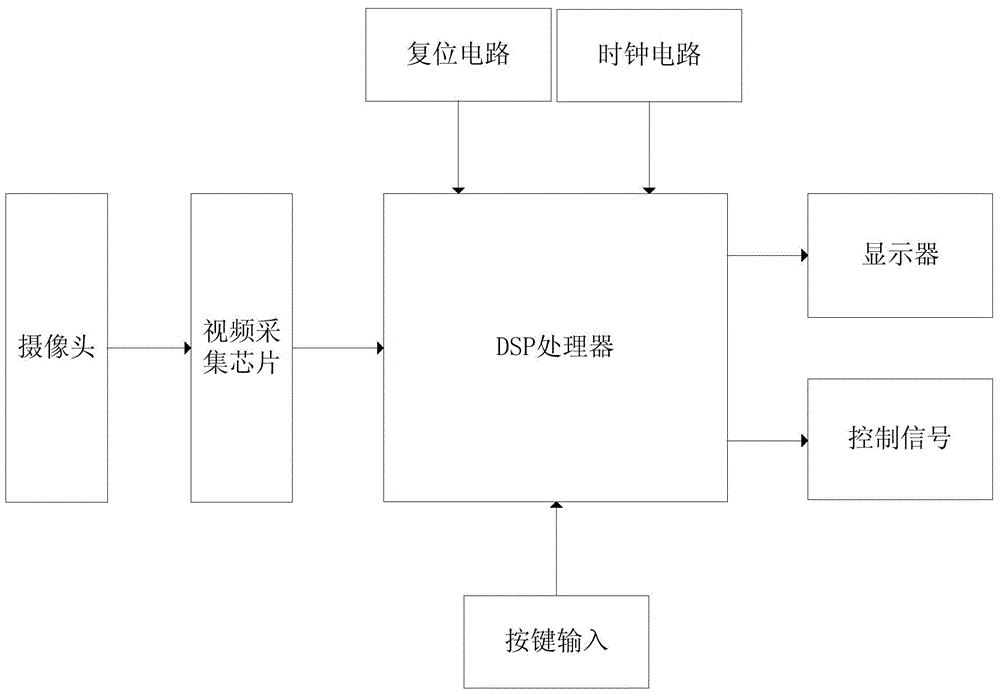

[0064] Such as figure 1 As shown, a tea picking machine cutter control system based on visual detection mainly includes:

[0065] Image acquisition unit:

[0066] It mainly includes CMOS camera and TVP5150 video decoder. The function of TVP5150 is to organize the video signal into BT656 video stream and directly transmit it to the video processing front-end VPFE of DM6437 processor. There is a light directly below the camera to make the picking machine adapt to picking at night and in rainy weather.

[0067] Image processing unit:

[0068] The main processor that completes image processing is DM6437, its main frequency is 600MHZ, the secondary cache includes L1P of 32KB RAM / Cache, L1D of 48KB RAM+32KB RAM / Cache, and L2 of 128KB RAM / Cache. The DM6437 processor has a 64-channel enhanced DMA controller EDMA3, which supports DMA transmission of various data types; it has an on-chip video...

Embodiment 2

[0083] Embodiment 2. A method for controlling the cutter of a tea picking machine based on visual detection

[0084] A method for controlling the knife of a tea picking machine based on visual detection. The processing of each tea long is mainly divided into the following steps:

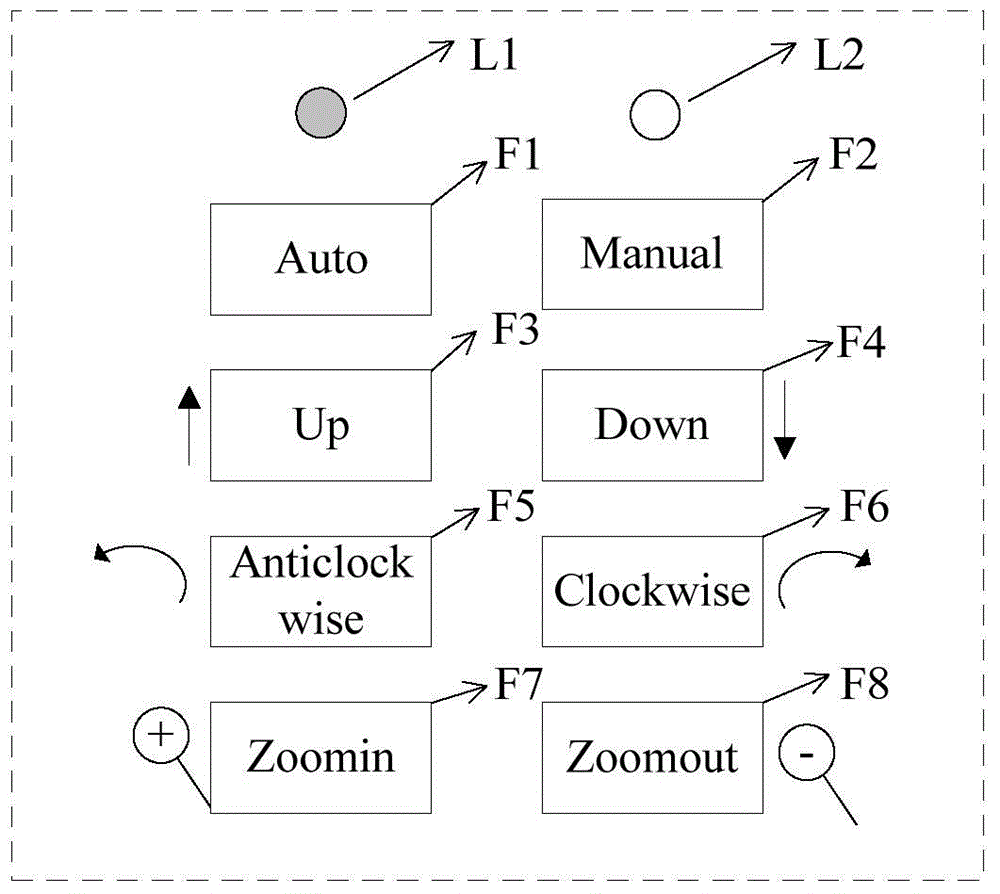

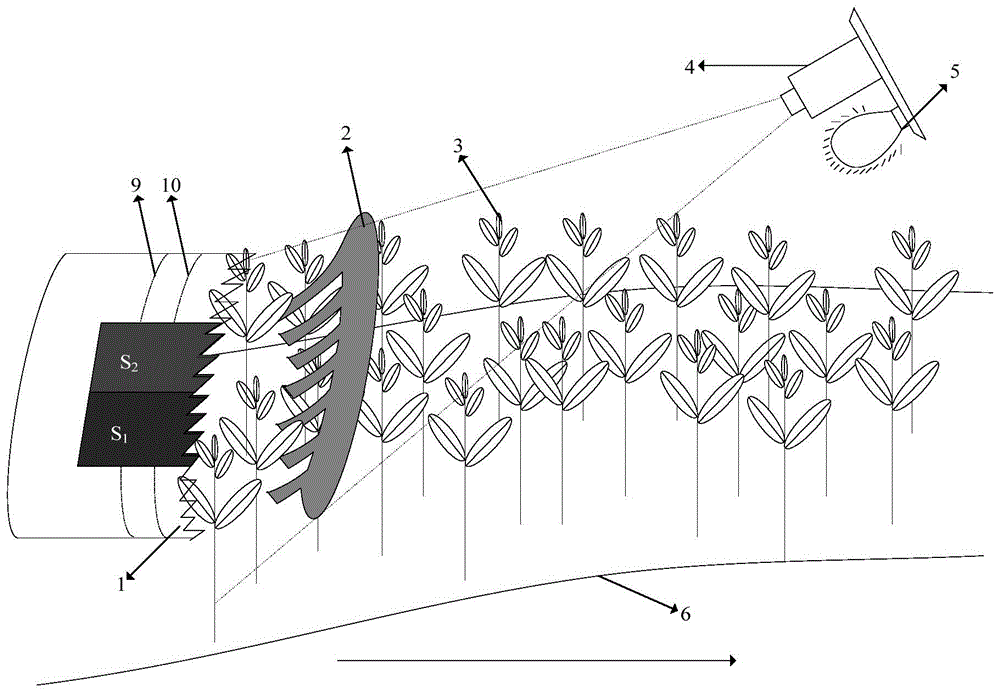

[0085] Step 1: Adjust the initial position and angle of the cutter and the camera, and obtain the threshold value of whether the height and angle of the cutter need to be adjusted. Before picking each tea long, you need to manually adjust the height and angle of the cutter, and then adjust the angle and focus of the camera according to the position of the displayed image. Such as Figure 5 As shown, adjust the height and angle of the cutting knife so that the cutting blade is at the same height as the root of the bud, and the angle of the cutting knife is consistent with the growth of the crown of the tea tree. Adjust the camera angle and focal length so that the collected images meet the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com