A resin polishing disc

A polishing disc, resin technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., to achieve the effect of reducing processing costs, convenient production, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

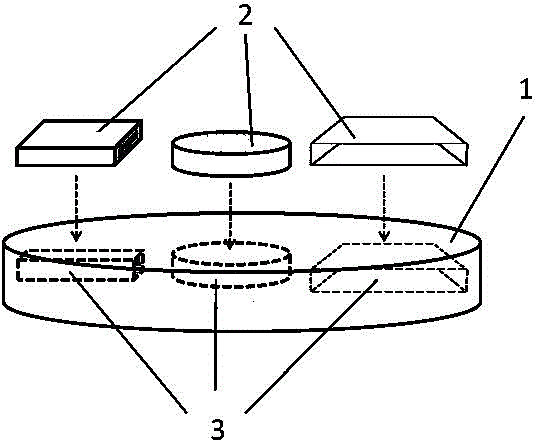

[0019] Such as figure 1 As shown, the resin polishing disc used for processing sapphire wafers according to the present invention includes a resin grinding tool 1 and a ceramic grinding disc 2 .

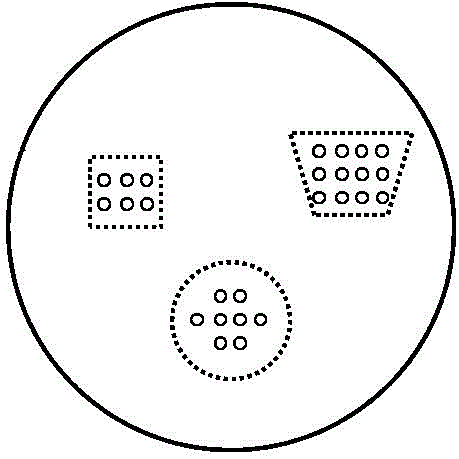

[0020] After artificially digging out a square, a circle and a trapezoidal hole 3 on the resin abrasive tool 1, add a small amount of glue or paste wax into the hole 3, and combine the sticking technology to make the ceramic abrasive disc 2 flat and It is bonded so that the ceramic grinding disc and the resin grinding tool are closely matched and bonded together.

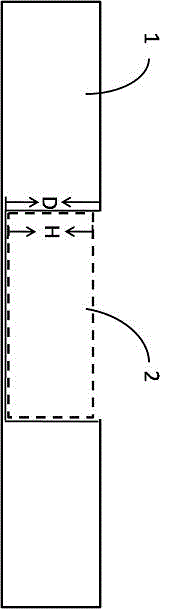

[0021] Such as image 3 As shown, there are several glue storage chambers on the bottom surface of the hole of the resin abrasive tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com