Energy conservation design method for elevator balance weight

A design method and elevator technology, which can be applied to lifting equipment in mines, sustainable buildings, elevators, etc., can solve problems such as low elevator efficiency and achieve satisfactory energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

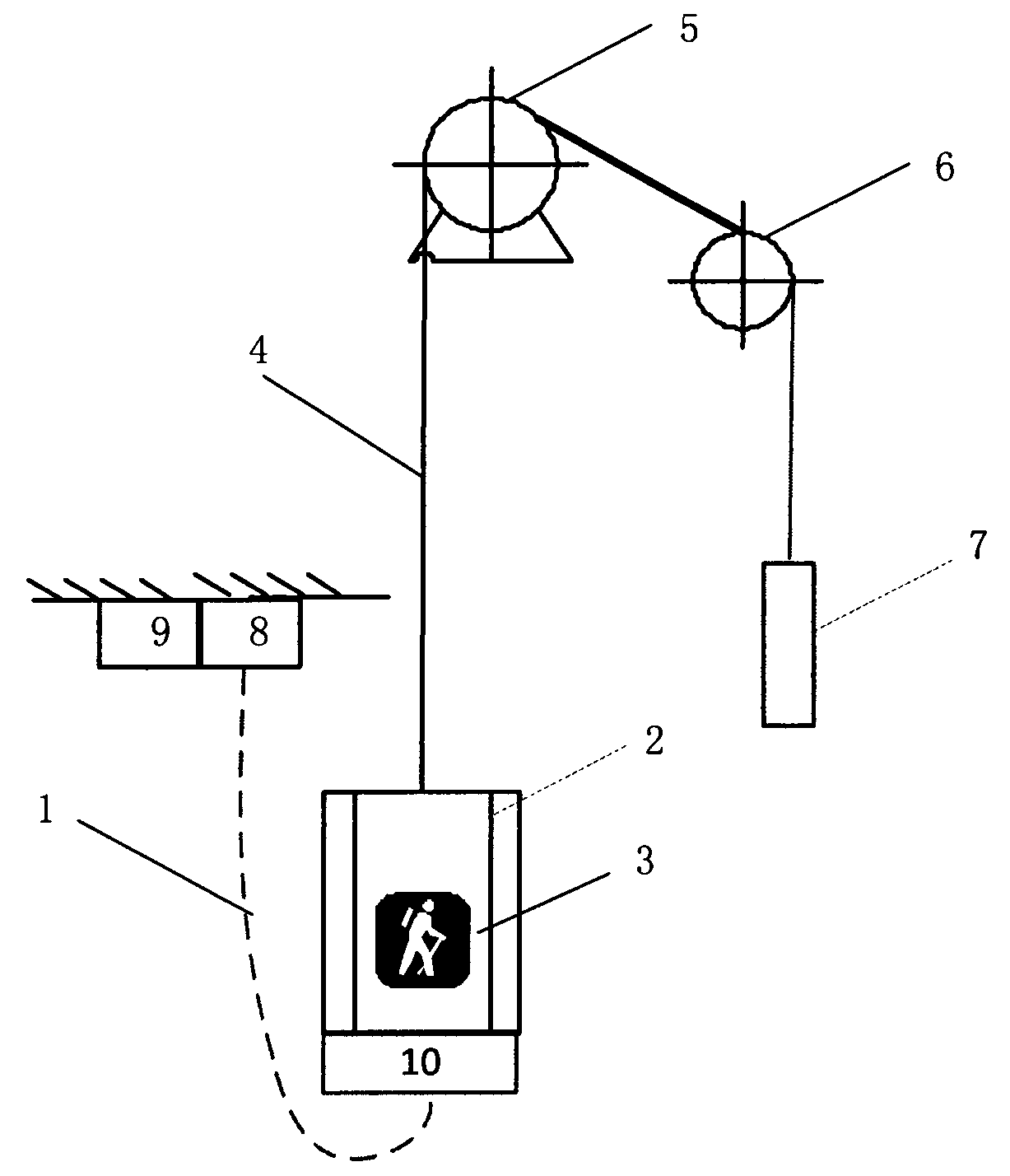

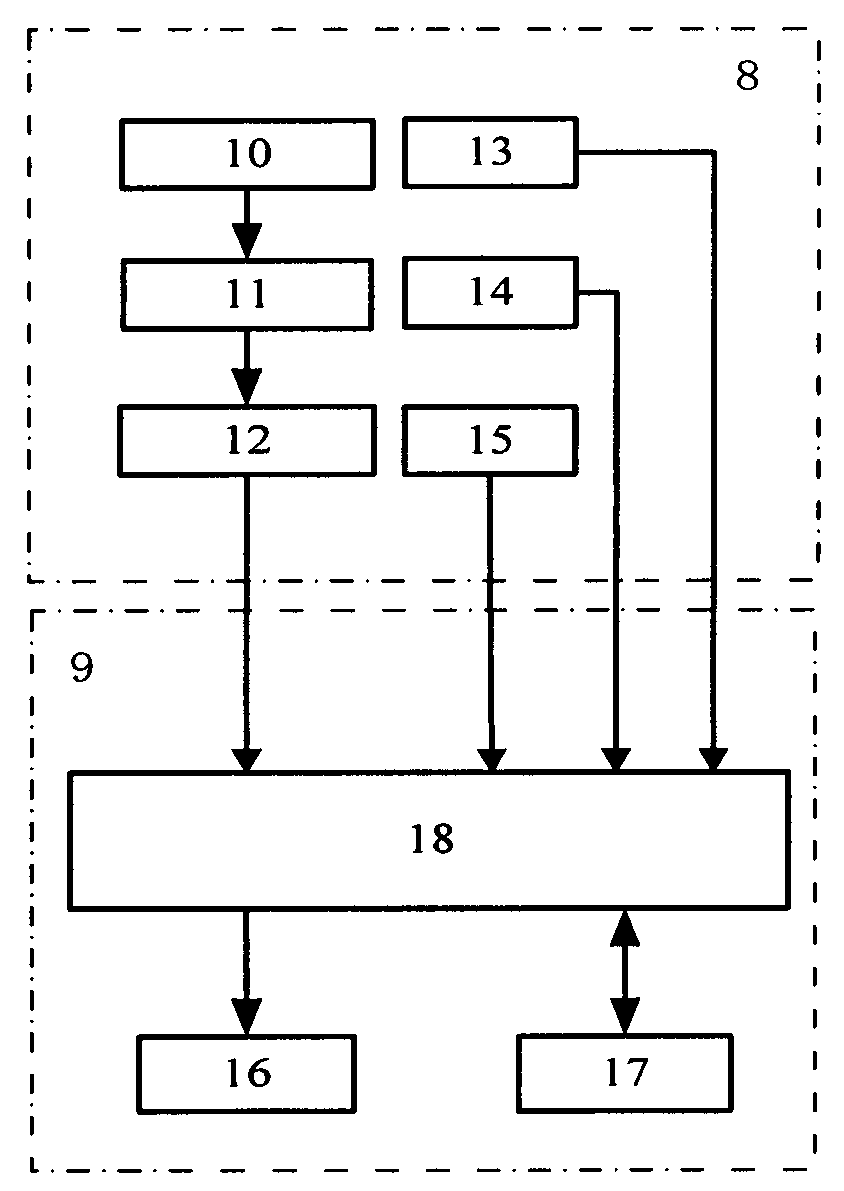

[0018] The following is combined with the specific figure 1, attached figure 2 The present invention is further described.

[0019] Figure 1 is The structural layout system diagram of the elevator in this embodiment.

[0020] figure 2 It is the structural diagram of the elevator load monitoring system.

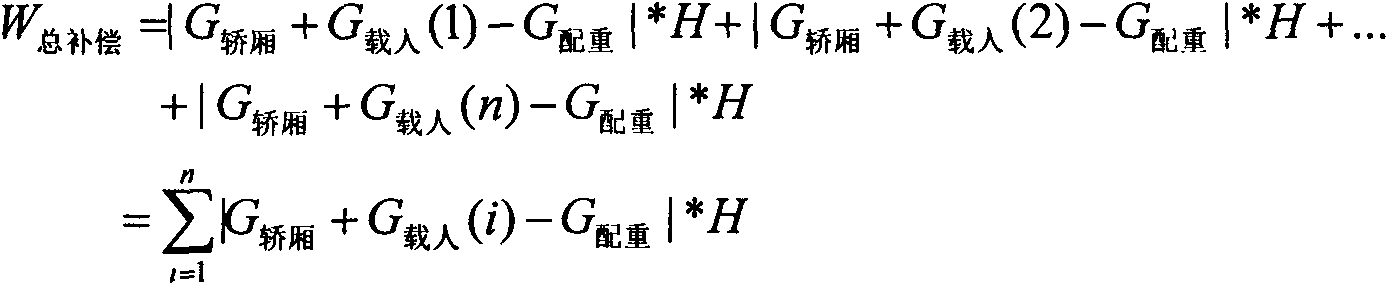

[0021] like Figure 1 Shown: the elevator structural balance system is made up of car 2 and passenger 3, steel cable 4, motor 5, pulley 6 and counterweight 7. During the operation of the elevator, the weight of the car is composed of the weight of the car 2 and the passenger 3 . The weight of the car and the weight of the counterweight 7 form a balance system through the steel cable 4, the motor 5, and the pulley 6; when the weight values of the two are not equal, the difference is performed by the motor 5 to complete the running task; of course, in the actual elevator system The frictional resistance is also overcome by the motor doing work. The accompanying cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com