Preparation method for toddalolactone

A technology of double-faced needle and aluminum oxide, which is applied in the biological field and can solve the problems of complex preparation methods, few disclosures, and low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

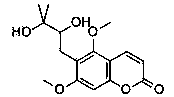

Image

Examples

Embodiment 1

[0013] Take Feilongzhang blood and crush it through an 80-mesh sieve, take 5kg and place it in a CO2 supercritical extraction tank for extraction, feed liquid CO2 with a flow rate of 3ml / min / g raw material, and simultaneously feed anhydrous methanol solution with a flow rate of 0.3ml / min / g raw material, extraction pressure 25Mpa, extraction temperature 45°C, extraction 90min, the extract obtained by analysis was dissolved in 85% methanol solution, added 400g basic aluminum alumina to dry and packed, followed by 10 times of column volume petroleum ether, 10 times of column volume Elute with volumetric ethanol solution, collect the ethanol solution to recover to 100ml, add 100ml chloroform, refrigerate and crystallize, filter out the crystals and recrystallize with absolute ethanol solution, dry to obtain 3.5g of ethanol with a content of 98.2%.

Embodiment 2

[0015] Take Feilongzhang blood and crush it through a 60-mesh sieve, take 5kg and place it in a CO2 supercritical extraction tank for extraction, feed liquid CO2 with a flow rate of 4ml / min / g raw material, and simultaneously feed anhydrous methanol solution with a flow rate of 0.2ml / min / g raw material, extraction pressure 18Mpa, extraction temperature 40°C, extraction 60min, the extract obtained by analysis was dissolved in 90% methanol solution, added 300g basic aluminum alumina to dry and packed, followed by 15 times of column volume petroleum ether, 10 times of column volume Elute with volumetric ethanol solution, collect the ethanol solution and recover to 80ml, add 50ml of chloroform, refrigerate and crystallize, filter out the crystals and recrystallize with absolute ethanol solution, dry to obtain 3.8g of staurein with a content of 98.2%.

Embodiment 3

[0017] Take Feilongzhang blood and crush it through a 40-mesh sieve, take 5kg and place it in a CO2 supercritical extraction tank for extraction, feed liquid CO2 at a flow rate of 1ml / min / g of raw materials, and simultaneously feed anhydrous methanol solution at a flow rate of 0.3ml / min / g raw material, extraction pressure 30Mpa, extraction temperature 50°C, extraction 120min, the extracted extract was dissolved with 90% methanol solution, added 350g basic aluminum alumina, dried and loaded into the column, followed by 10 times the column volume of petroleum ether, 10 times the column volume Elute with volumetric ethanol solution, collect the ethanol solution and recover to 80ml, add 80ml of chloroform, refrigerate and crystallize, filter out the crystals and recrystallize with absolute ethanol solution, dry to obtain 3.5g of staurein with a content of 98.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com