Thermosetting phenolic resin used for environment-friendly type phenolic aldehyde electronic encapsulating material

A technology of phenolic resin and encapsulating material, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problem that heat resistance and breakdown strength cannot meet the requirements of electronic components, the manufacturability of phenolic electronic encapsulating material, production Efficiency cannot meet the problems of electronic components and other problems, and achieve the effects of good breakdown strength, fast drying speed and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

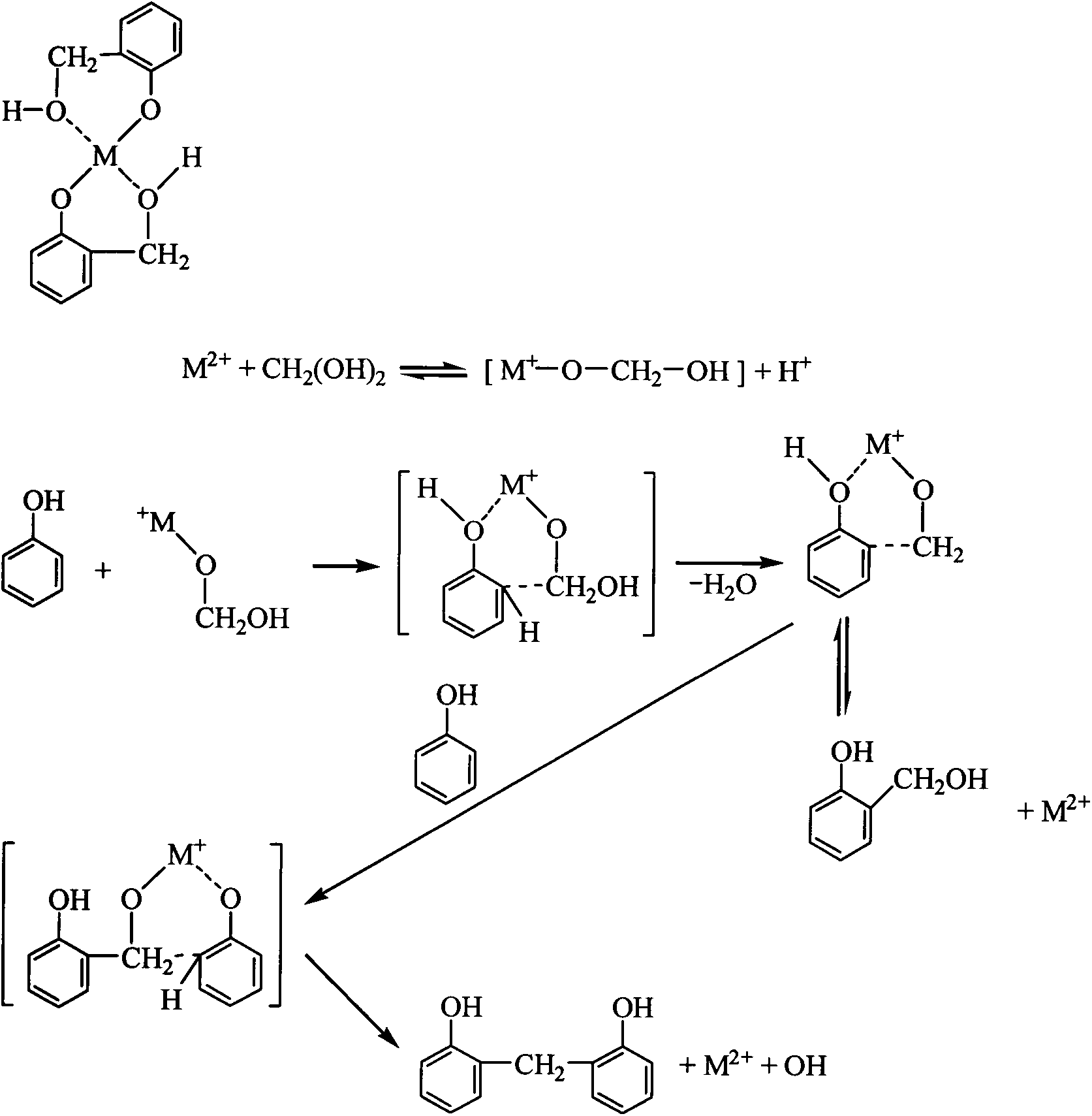

Method used

Image

Examples

Embodiment Construction

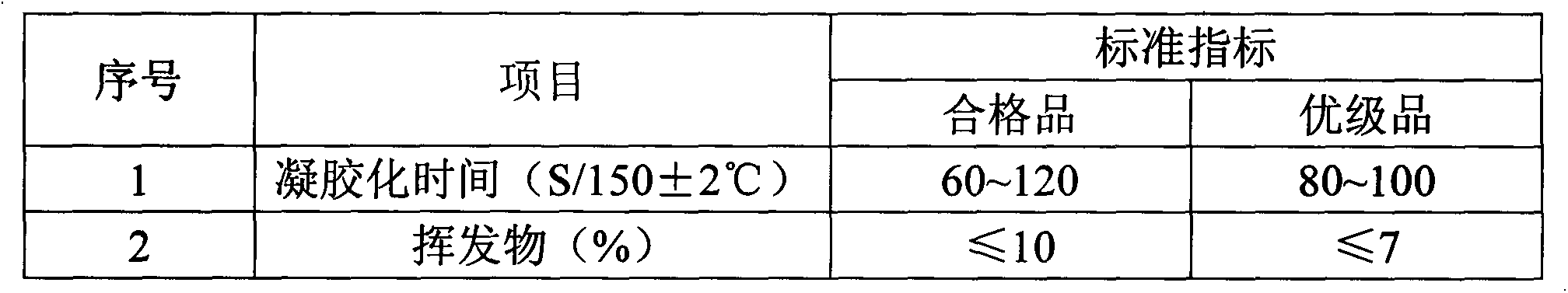

[0022] The present invention is achieved like this: it is raw material with phenol, aniline, paraformaldehyde, and light magnesium oxide is made catalyst, and the weight percentage of raw material is: phenol: paraformaldehyde: aniline: light magnesium oxide=63: 29: 6.3 : 1.7, using light magnesium oxide as a catalyst, reacting phenol, aniline and paraformaldehyde as raw materials under normal pressure, then dehydrating under negative pressure until the control index is reached, and then breaking the package after cooling.

[0023] The production method of the thermosetting phenolic resin for environment-friendly phenolic electronic encapsulation material is:

[0024] 1. Raw material ratio and standard:

[0025] material name

Specification

% by weight

standard

phenol

Superior product

63

GB / T339-2001

96±1%

29

Q / 321100ABJ001-2011

aniline

qualified

6.3

GB / T2961-2006

Light magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com