Slurry pump bracket end bearing oil seat structural combination

A slurry pump and skeleton oil seal technology, which is applied in the field of bearing oil seal structure combination at both ends of the bracket, can solve problems such as oil leakage, bracket oil seal 5 heating, and reduced production efficiency, so as to reduce costs and reduce the frequency of replacement and maintenance , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

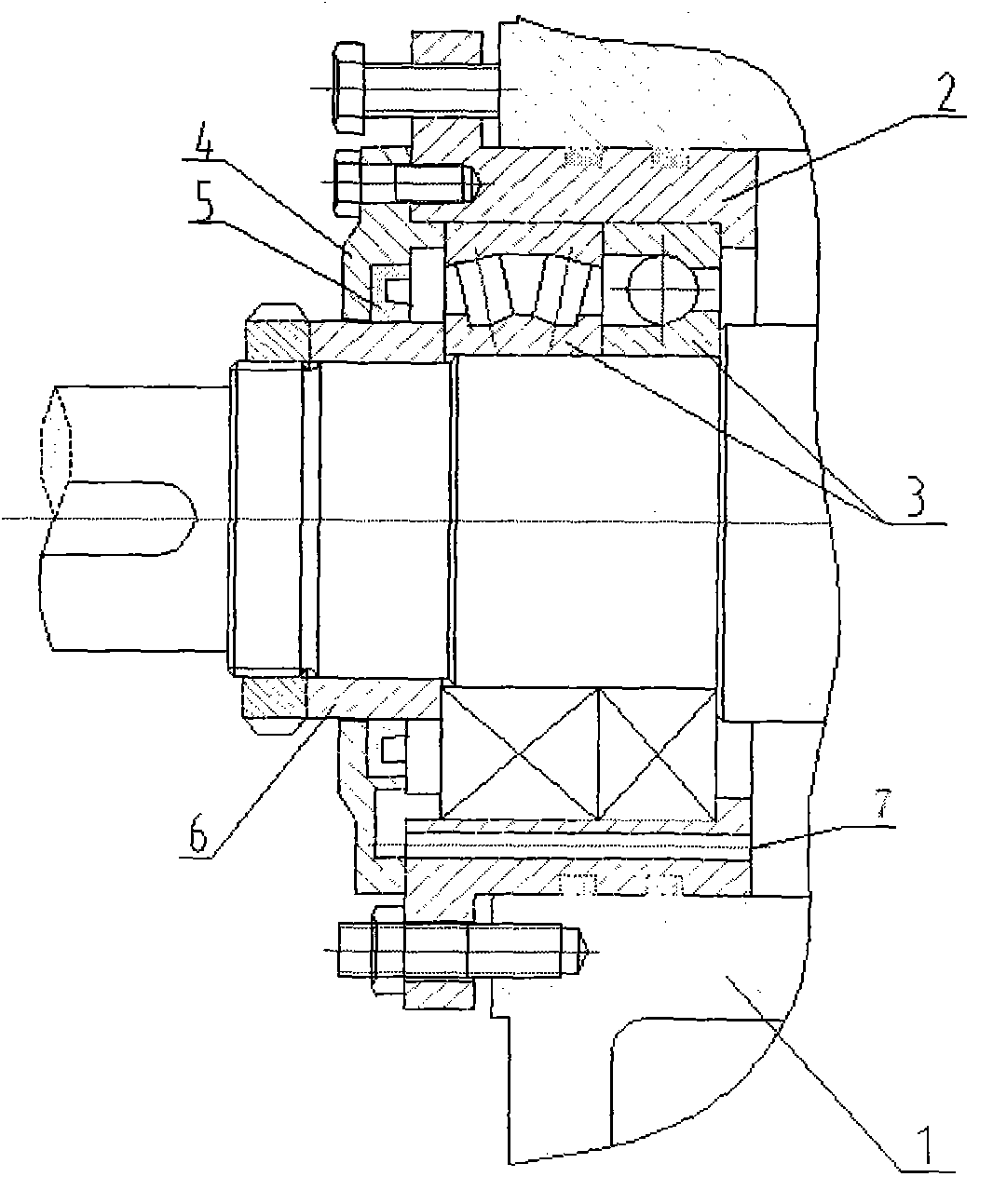

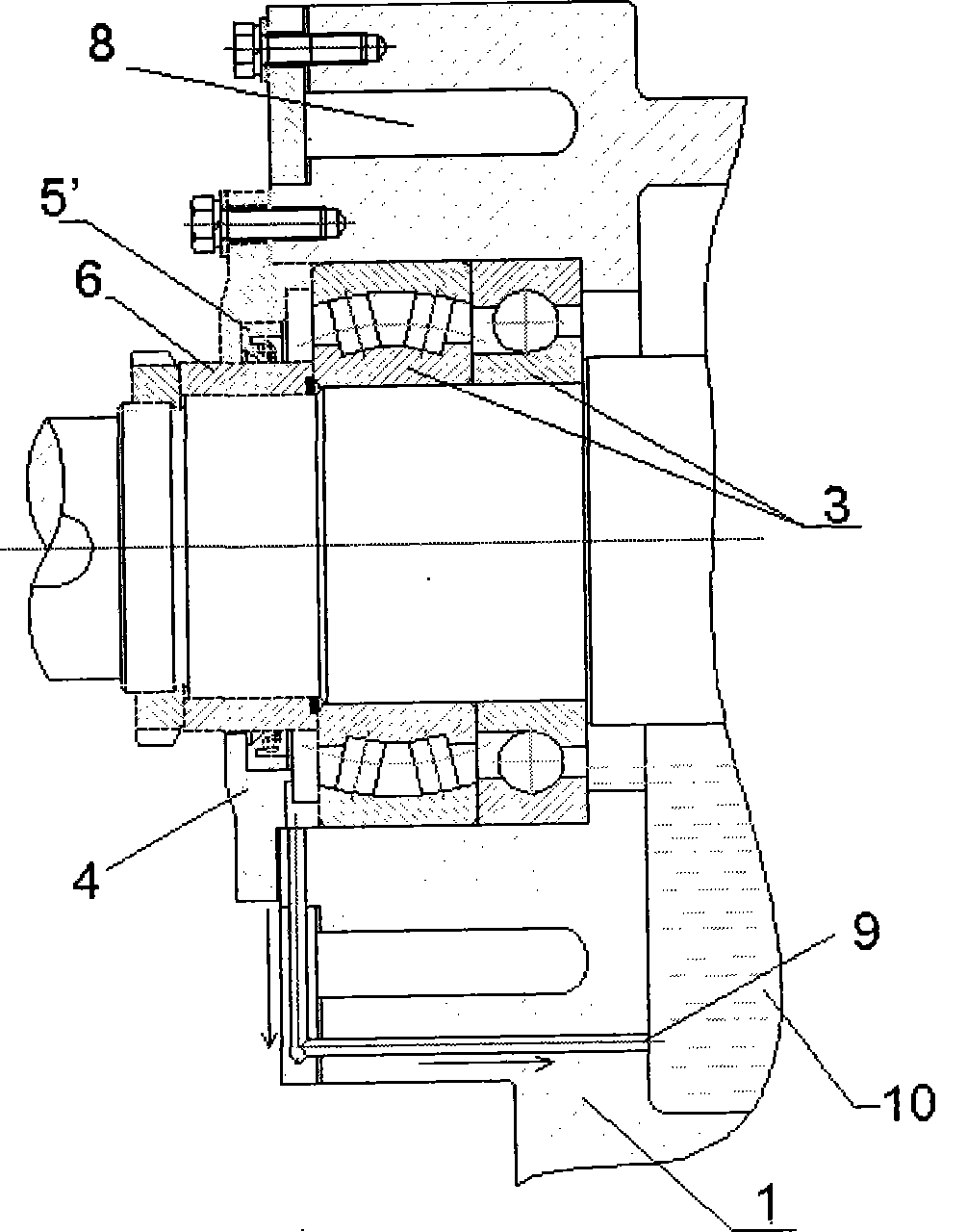

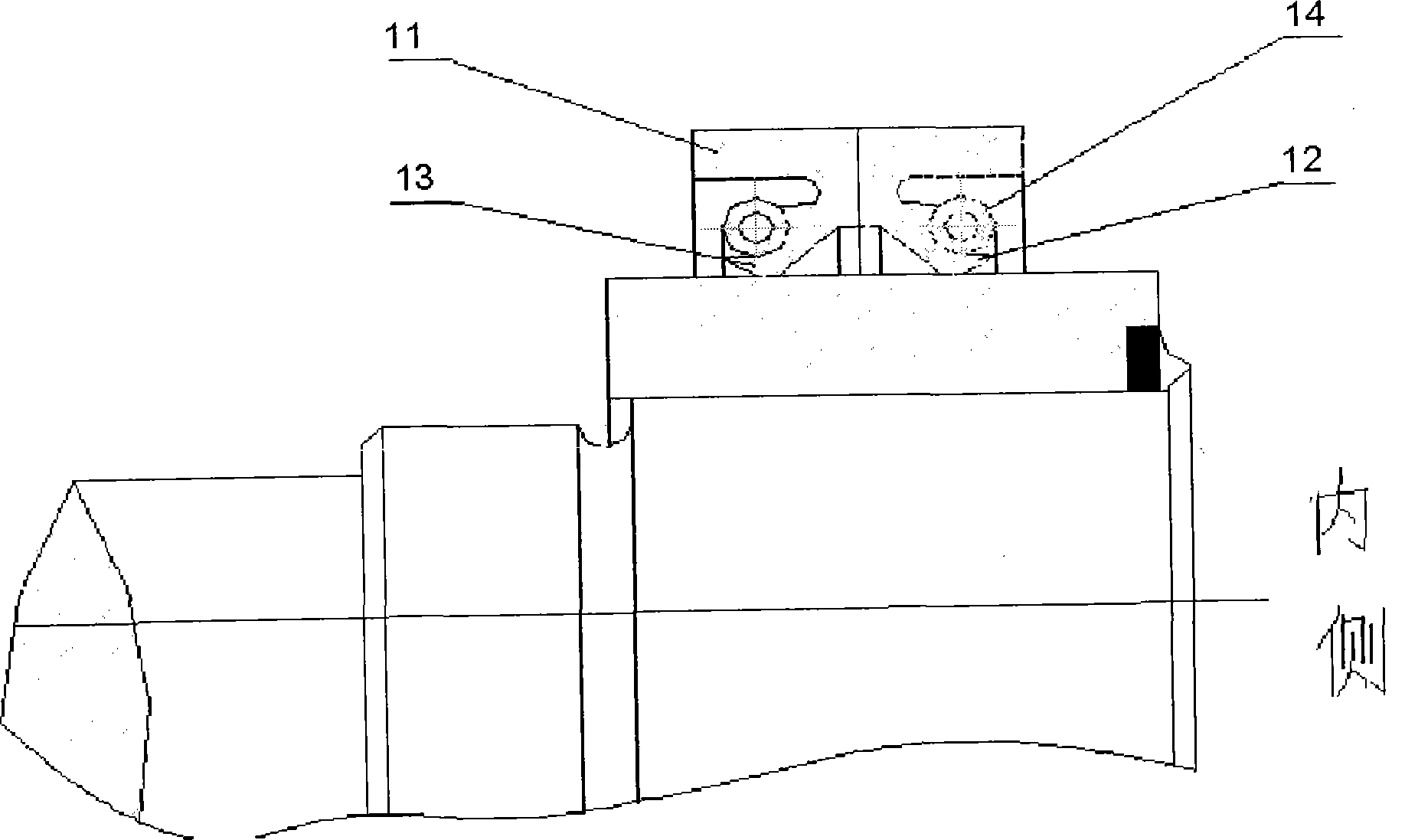

[0018] In order to prevent the oil seal of the bracket of the slurry pump from leaking, to run safely and reliably for a long time, and to ensure the reliability of the whole pump, the following modifications have been made to the oil seals of the end covers on both sides of the bracket, see figure 2 , which shows the oil seal structure combination of the rear bearing end cover of the slurry pump according to the present invention, including the bracket body 1, the bearing 3, the bearing end cover 4, the oil seal 5', and the shaft sleeve which is sleeved on the pump shaft and rotates with the shaft 6. Cooling water channel 8, vertical oil drain channel 9 and engine oil tank 10. The oil seal 5' is installed in the flange of the bearing end cover 4 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com