Simple combined gear

A combined and simple technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of high equipment use and maintenance costs, not in line with the maximization of corporate interests, and small transmission power, etc. problems, to achieve the effect of saving production time, low professional level requirements, and simple machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

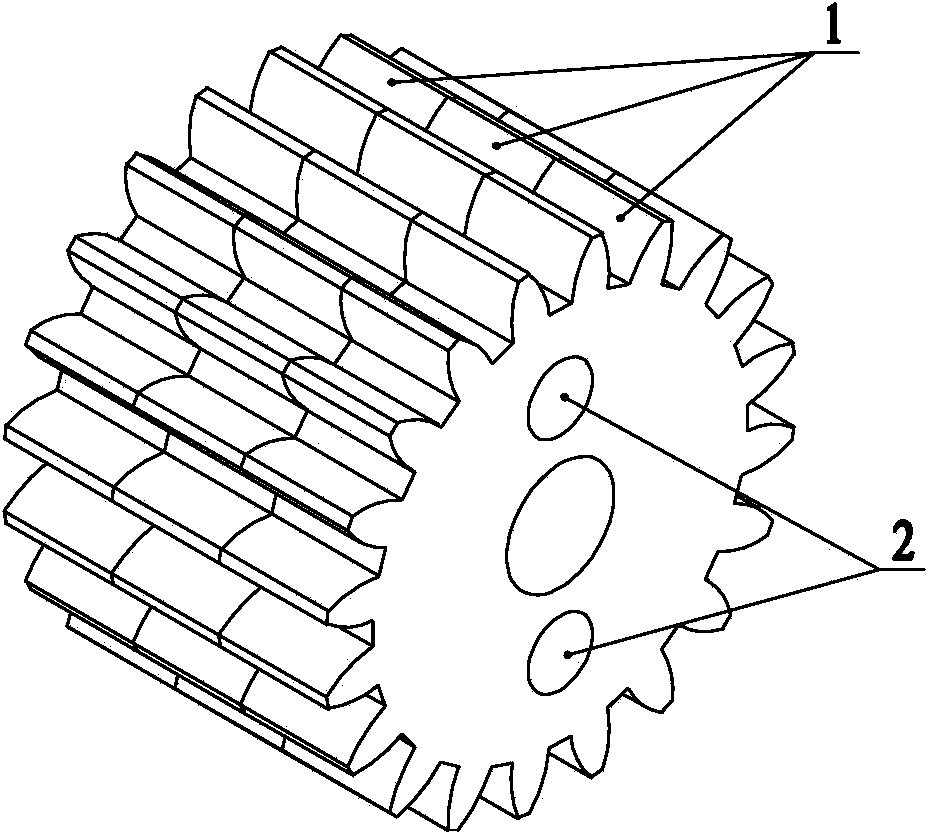

[0014] like figure 1 As shown, the simple combined gear in the embodiment is mainly composed of three single-piece gears 1 of the same specification, and the three single-piece gears 1 are stacked in sequence and connected by riveting through cylindrical pins 2 .

[0015] like figure 1 As shown, the monolithic gear 1 in the present invention is a monolithic gear 1 obtained by a cold stamping die, and the disc surface of the monolithic gear 1 is provided with through holes uniformly arranged along the circumferential direction, and cylindrical pins 2 are arranged in the through holes. The three single-piece gears 1 are riveted together by a riveting machine. It is required that the height of the two ends of the riveted cylindrical pin 2 higher than the end face of the gear does not exceed 1mm.

[0016] The simple combined style gear of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com