A liquid fuel instant gasification combustion furnace

A technology of liquid fuel and combustion furnace, which is applied in the direction of liquid heating fuel, heating fuel, household stove/stove, etc. It can solve the problems of liquid leakage, high pressure, and failure, and achieve uniform fire dispersion, good heating effect, and improved thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

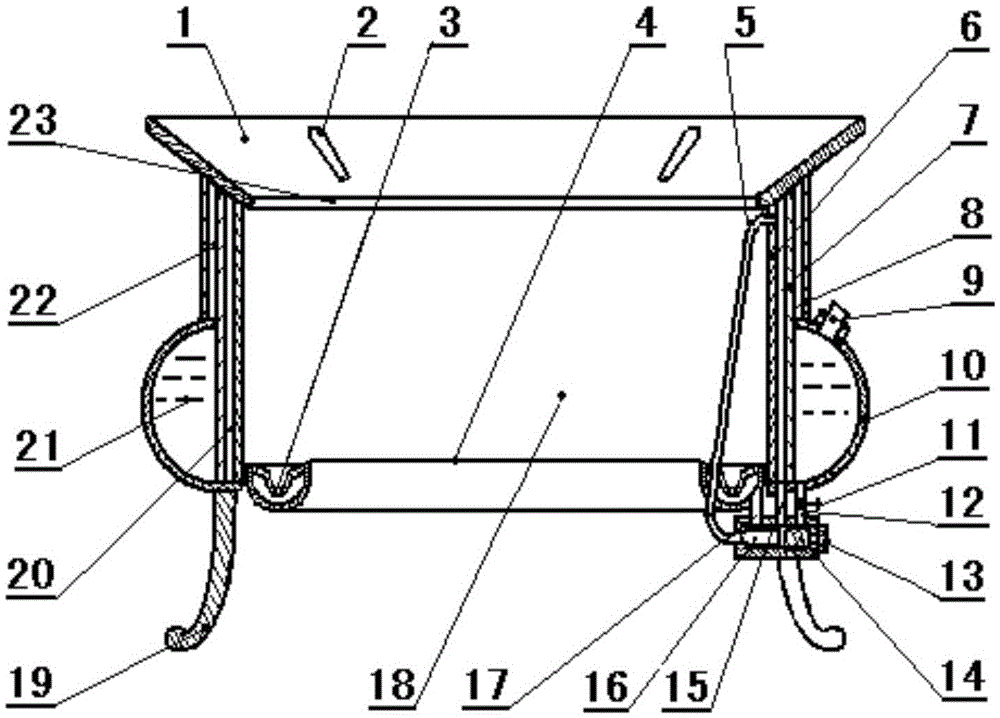

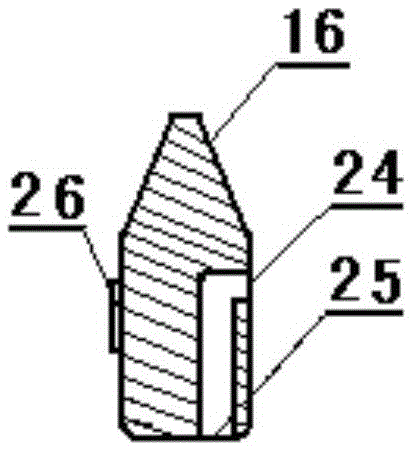

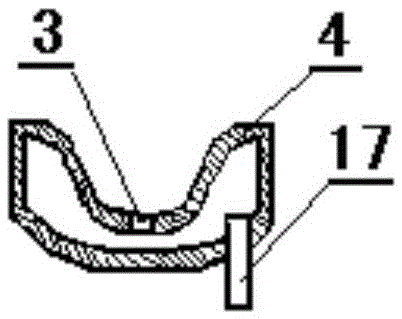

[0029] A small-scale liquid fuel instant gasification combustion furnace, which is characterized in that it is set up to include: a furnace stand 1, a combustion groove ring pipe 4, a gas supply pipe 5, a heat transfer layer 6, a gas-liquid barrier layer 7, an insulation layer 8, and a liquid supply ring groove 10. The liquid-gas control valve 13 and the stove foot 19; the heat transfer layer 6 is the innermost layer of the combustion furnace, and the heat transfer layer 6 is connected with the combustion groove ring pipe 4 to form a combustion chamber 18; The insulation layer 7 is the middle layer of the combustion furnace, and the gas-liquid insulation layer 7 and the heat transfer layer 6 constitute the gasification chamber 20; the insulation layer 8 is the outermost layer of the combustion furnace, and the insulation layer 8 and the gas-liquid insulation layer 7 constitute The gas holding chamber 22; the liquid supply ring groove 10 is provided on the outer wall of the lower...

Embodiment 2

[0038] A medium-sized liquid fuel instant gasification combustion furnace, which is characterized in that it is set up to include: a furnace stand 1, a combustion groove ring pipe 4, a gas supply pipe 5, a heat transfer layer 6, a gas-liquid barrier layer 7, a heat preservation layer 8, and a liquid supply ring groove 10. The liquid-gas control valve 13 and the stove foot 19; the heat transfer layer 6 is the innermost layer of the combustion furnace, and the heat transfer layer 6 is connected with the combustion groove ring pipe 4 to form a combustion chamber 18; The insulation layer 7 is the middle layer of the combustion furnace, and the gas-liquid insulation layer 7 and the heat transfer layer 6 constitute the gasification chamber 20; the insulation layer 8 is the outermost layer of the combustion furnace, and the insulation layer 8 and the gas-liquid insulation layer 7 constitute The gas holding chamber 22; the liquid supply ring groove 10 is provided on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com