Post evaluation system for polluted soil remediation

A post-evaluation and soil technology, applied in the field of post-evaluation systems for contaminated soil remediation, can solve the problems of long test period, high cost consumption, and difficult operation, so as to improve the utilization rate of equipment space, improve the accuracy of measurement, and facilitate accurate measurement. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific working method of a post-remediation evaluation system for contaminated soil is described in detail in conjunction with the accompanying drawings:

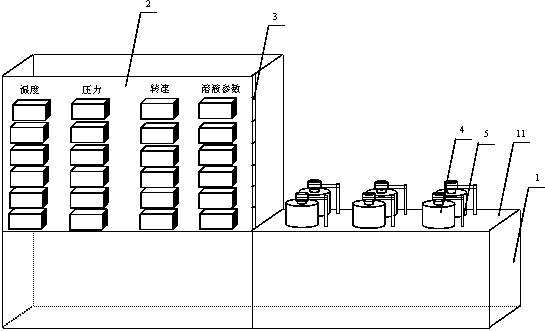

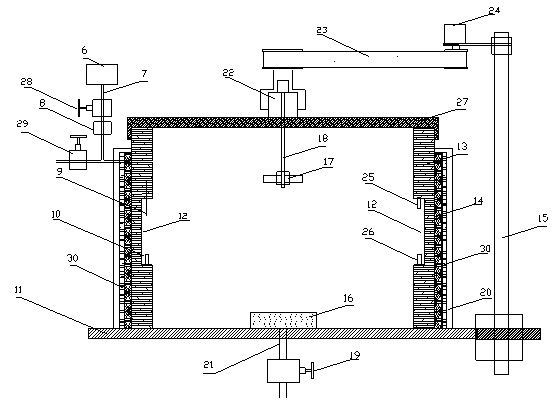

[0017] An evaluation system for post-remediation of polluted soil, including a bracket 1, a control and display panel 2, a signal acquisition and conversion system 3, a reactor 4, and a stirring system 5. There are six reactors 4, and the reactor 4 can be Haian The reaction kettle produced by County Petroleum Research Instrument Co., Ltd. is divided into two rows and distributed on the instrument table 11 of the support 1 at equal intervals. Six reaction kettles controlled by an independent control system are composed of two rows of parallel and equal intervals. The structure is compact. It is easy to operate and improves the utilization rate of equipment space. The inner wall 13 of the reaction kettle 4 is provided with two symmetrical grooves 12, the temperature sensor 9 and the conductivity electrode 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com