High-dynamic charge type piezoelectric ceramic drive power supply

A piezoelectric ceramic drive, piezoelectric ceramic technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of low output bandwidth, large leakage current, dynamic Poor characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

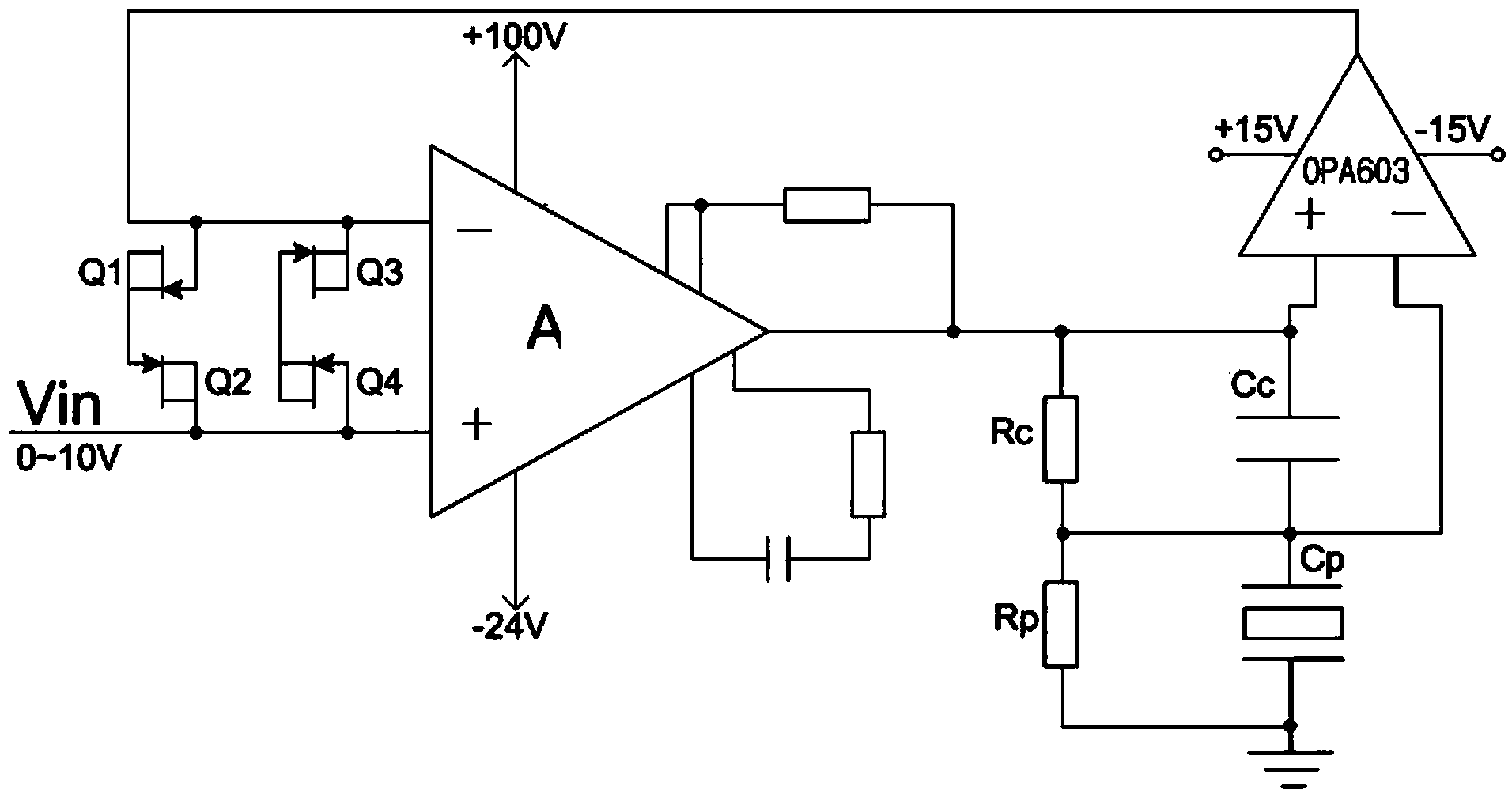

[0031] Such as figure 1 As shown, the signal output terminal VIN of the control module is connected to the positive terminal of the power amplifier A, wherein the control module is composed of a host computer, MCU, and DA converter. This is the prior art, and the power operational amplifier A is a high-voltage MOSFET operational amplifier. The terminals are connected with field effect transistors Q1, Q2, Q3, and Q4, the model is 2N4416, which are used for input protection. The signal output terminal of the power amplifier A is connected to a precision capacitor Cc. The precision capacitor Cc is a metal polycarbonate precision capacitor. The other end of the precision capacitor Cc is connected to a piezoelectric ceramic Cp, and one end of the piezoelectric ceramic Cp is grounded. One end of the precision capacitor Cc and one end of the piezoelectric ceramic Cp are respectively connected to the input end of the error integration operational amplifier. The error integrator is OPA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com