Structure for fixing stainless steel tubes in waste gas treatment tube

A fixed structure, exhaust gas treatment technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of stainless steel pipes such as difficulty, high cost, secondary pollution, etc., to save space, compact distance, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

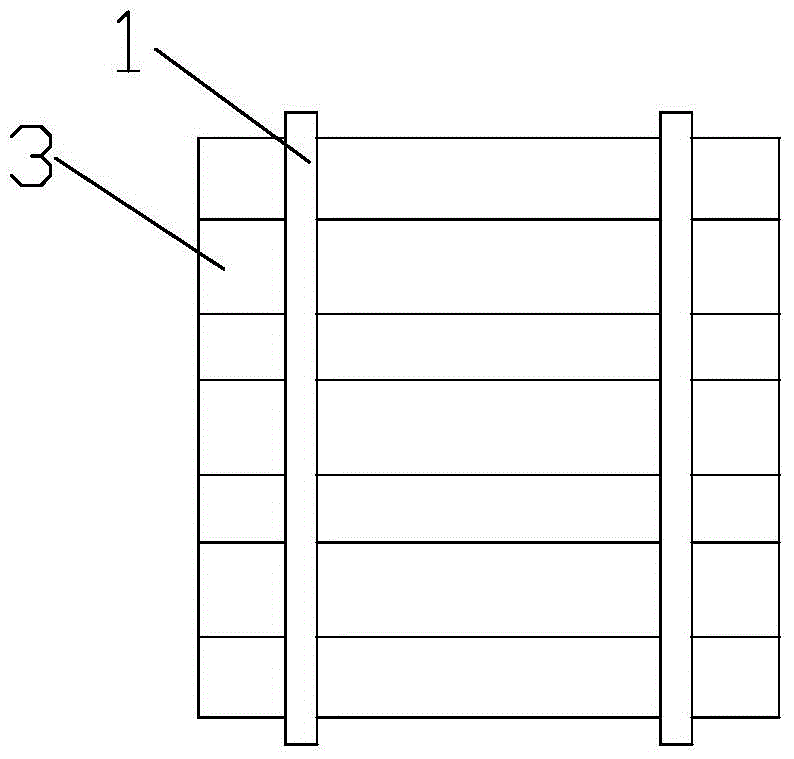

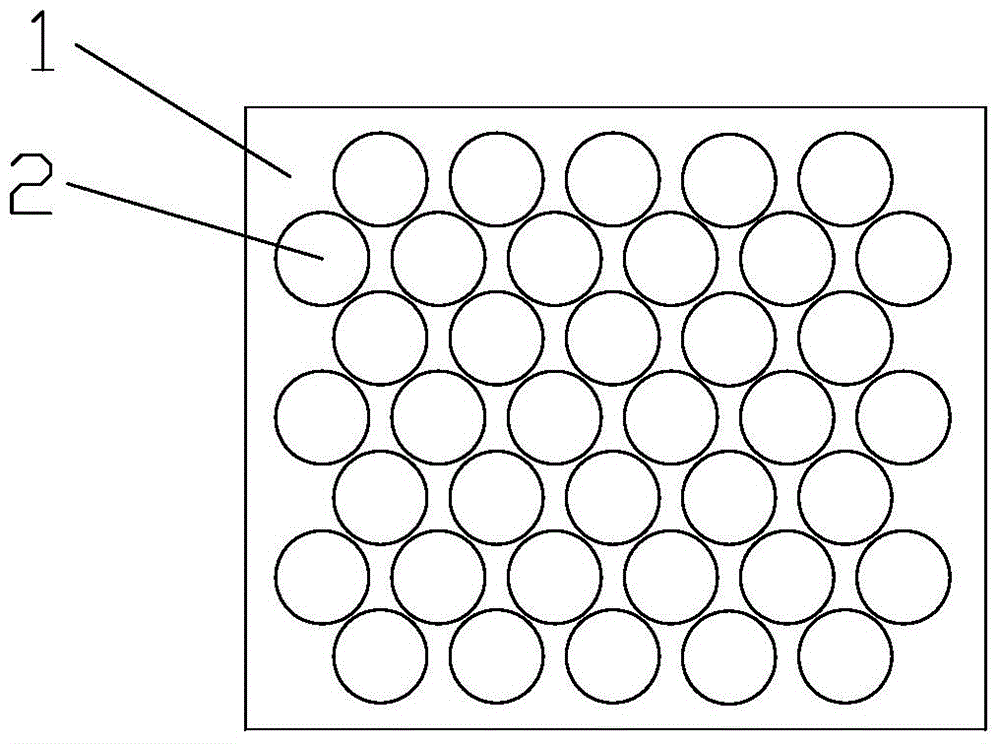

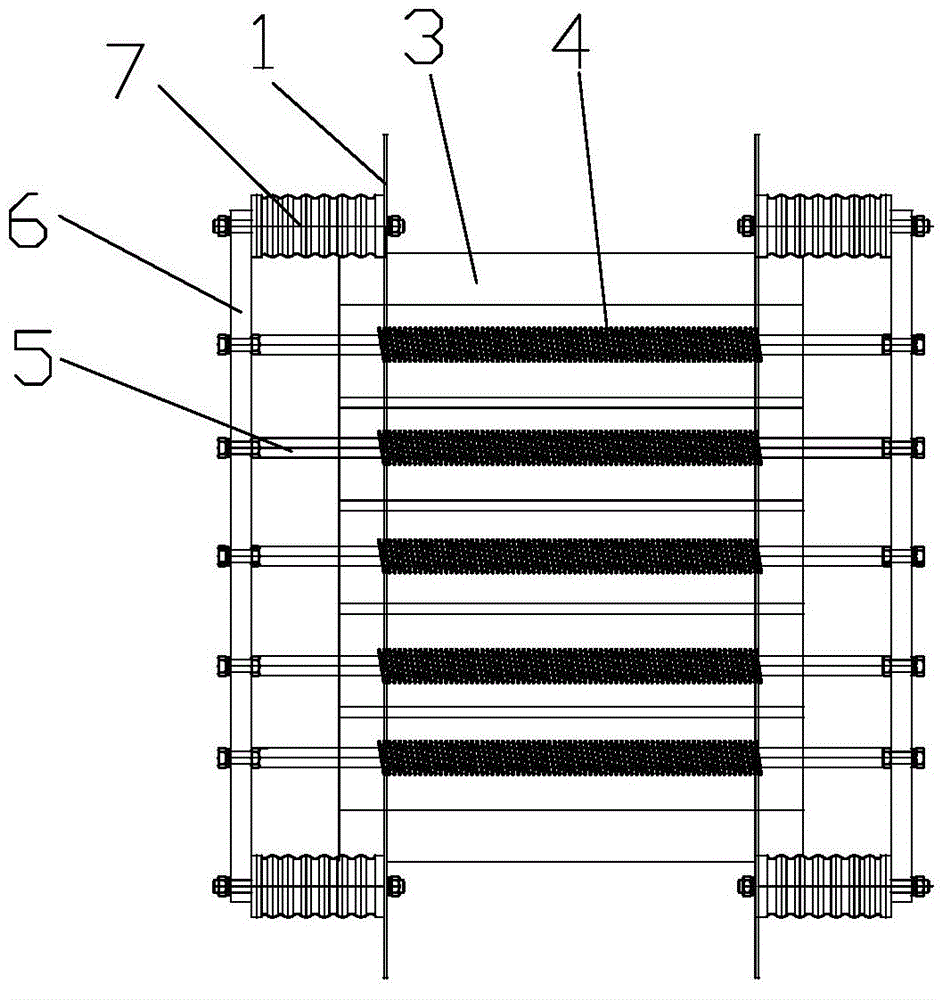

[0016] Embodiment: a kind of fixed structure of stainless steel pipe in exhaust gas treatment pipe, as figure 1 As shown, it includes two parallel and symmetrical stainless steel plates 1, and there are many pairs of identical and corresponding round holes 2 on the two sides of the stainless steel plates 1; a stainless steel pipe 3 is pierced in each pair of corresponding round holes 2 to make the stainless steel The steel pipe 3 is perpendicular to the stainless steel plate 1. Specifically, as figure 2 As shown, the circular holes 2 are arranged in multiple rows arranged horizontally, and the distance between adjacent circular holes in each row is equal; the upper middle or lower middle of a pair of adjacent circular holes in each row is one of the adjacent rows. Round holes, the centers of the three round holes are connected to form an isosceles triangle; the contact part of the stainless steel pipe 3 and the stainless steel plate 1 is fixed by welding.

[0017] In specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com