Making method of hollow fiber membrane filter element sealing layer with three-dimensional structure

A technology of three-dimensional structure and production method, which is applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven distribution of hollow fiber membrane tubes, waste of materials, and many manual operations, etc., to facilitate scale Production, avoiding defective products, and reducing labor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

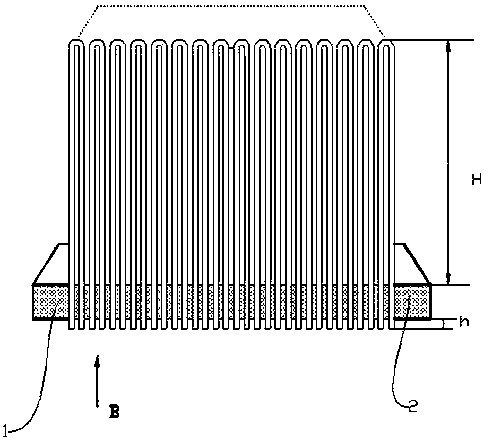

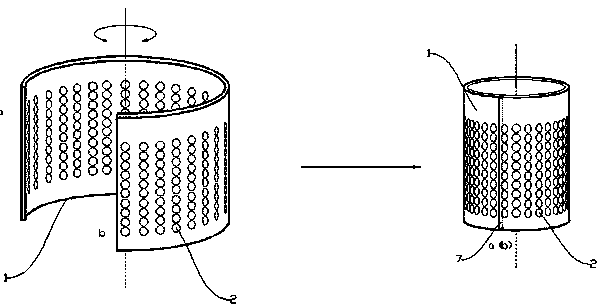

[0028] A method for manufacturing a sealing layer of a hollow fiber membrane filter element with a three-dimensional structure, the sealing layer (1) is cast from an adhesive material, and the opening ends of a plurality of hollow fiber membranes (2) pass through the sealing layer from the outer surface of the sealing layer To its inner surface, take the manufacture of a cylindrical three-dimensional sealing layer as an example, including the following steps:

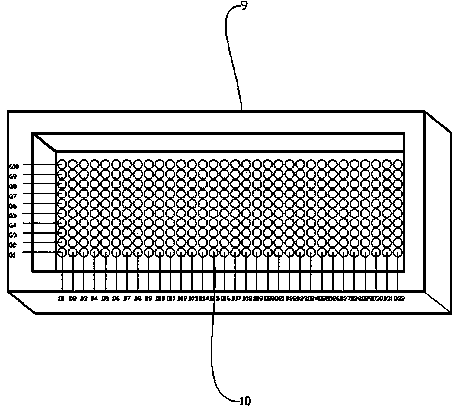

[0029] (1) Make a casting mold. First make a mold (9) whose inner cavity is a cuboid, such as image 3 As shown, the length of the inner hollow cuboid is the perimeter of the cylindrical sealing layer, the width is the height of the sealing layer, and the height is the thickness of the sealing layer. Several through holes (10) are evenly distributed on the bottom of the mold. The horizontal serial number of the through holes is Dn, and the vertical serial number is Gn. The diameter of the through hole is smaller than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com