Optimization connecting structure of metal pipe fittings and implementation method thereof

A technology for connection structures and metal pipe fittings, which is applied in the connection of rods, connection components, metal processing equipment, etc., can solve the problems of small connection volume, connection strength and toughness decline, and achieve good toughness, increased safety, and comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

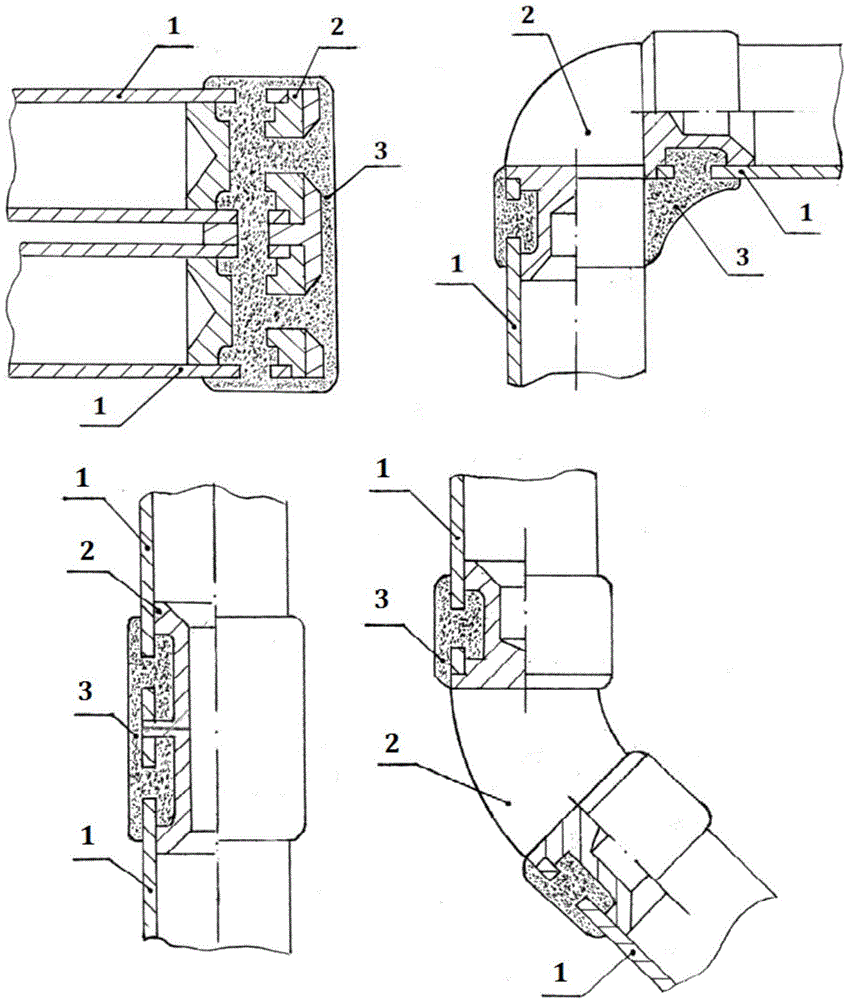

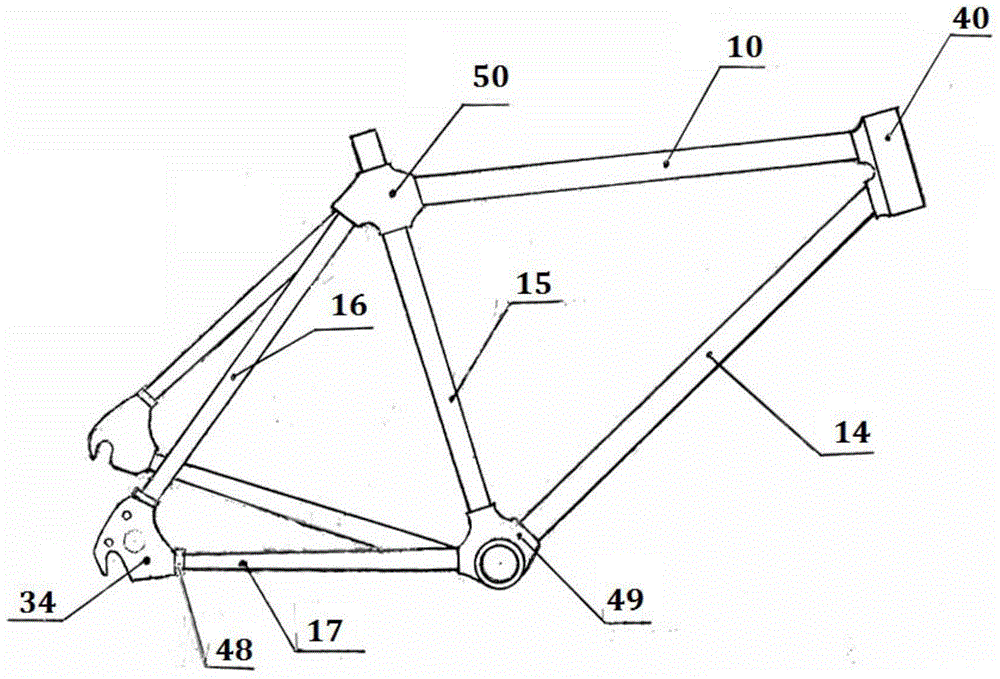

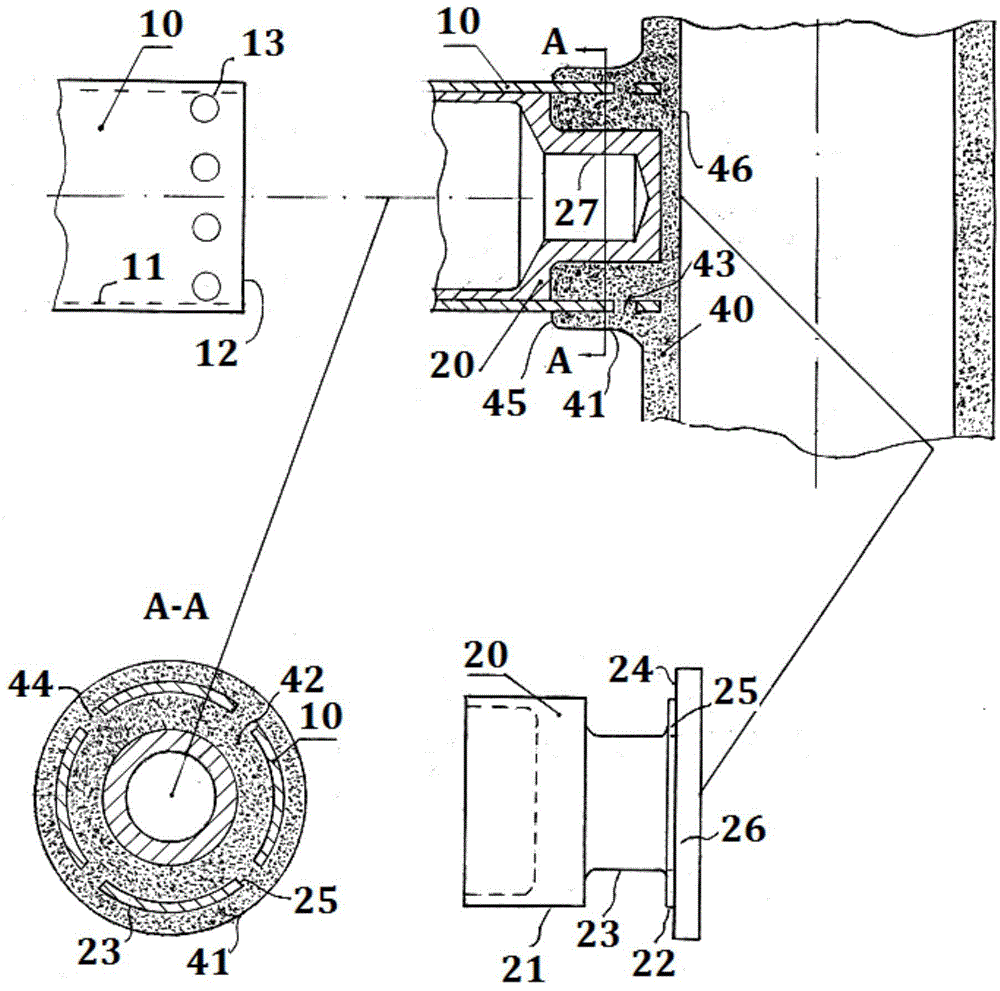

[0059] Example 1. See figure 2 , image 3 , Figure 4 , the high-strength connection between the front tube 40 of the frame and the upper tube 10 and the lower tube 14 and the combined configuration of the tube material:

[0060] 1.1) The upper tube 10 and the lower tube 14 adopt Ti3AL2.5V titanium alloy seamless round tube, the wall thickness = 0.8mm, the inner hole = 30.0mm; the peripheral through hole of the connecting end of the upper tube 10 and the lower tube 14 is processed by mechanical or laser = 7.0mm, quantity = 6 pieces; the front pipe 40, plugs 20 and 28 are made of AZ80A‐T4 and T6 magnesium ingots and rods respectively, the former is processed by casting and forging composite machine, and the latter is processed by lathe.

[0061] 1.2) Chamfer, deburr, clean and dry the sharp edges of pipe fittings and plugs.

[0062] 1.3) Carry out micro-arc oxidation insulation treatment on the surface of the plug.

[0063] 1.4) Plug the plugs 20 and 28 into the inner hole...

Embodiment 2

[0066] see figure 2 , image 3 , Figure 5 , the high-strength connection between the frame riser joint 50, the upper tube 10 and the upper fork 16, and the material combination configuration of the pipe fittings:

[0067]2.1) In the inner hole of the connection part at the upper end of the standpipe 15, the axial length = 50.0mm, the pipe thickness increased = 1.0mm, and the local diameter expansion process was increased by 8.0mm: Then connect the upper pipe 10 and the upper fork 16 At the center position, the through-holes 51 and 52 through which the upper tube 10 and the upper fork 16 can enter are oppositely processed; the width of the inner hole of the upper fork 16 is 12.1 mm, and the thickness 30 of the plug body at the end of the flat corner joint 29 is 12.0 mm. mm, the sliding fit clearance between the two is 0.1mm, and the thickness of the middle end and the top end is 7.0mm. Except that the upper pipe 10 is made of Ti3AL2.5V titanium alloy seamless pipe, the res...

Embodiment 3

[0073] see Figure 7 , Figure 9 , the high-strength connection of the shoulder cover joint 58 and the front fork vertical tube 60 and two left and right front fork tubes 62 and the combined configuration of the pipe fitting material:

[0074] 3.1) The two front fork tubes 61 are made of Ti3AL2.5V titanium alloy seamless pipe, and the rest of the vertical pipe 60, plug head 20, shoulder cap double plug head 38 and shoulder cap joint 58 are respectively made of 7050-T4 and T6 aluminum alloy seamless pipes , bars and ingots.

[0075] 3.2) Chamfer, deburr, clean and dry the sharp edges of pipe fittings and plugs.

[0076] 3.3) Perform micro-arc oxidation insulation treatment on the surface of pipe fittings and plugs.

[0077] 3.4) Insert the plug head 20 into the inner hole of the connecting end of the vertical pipe 60, then place it in the positioning circular groove 35 of the double plug head 38 of the shoulder cover, and connect the axial through hole 25 of the plug head wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com