Brake shoe body preparation material for railway high-power locomotive synthetic brake shoes and preparation method thereof

A synthetic brake shoe and high-power technology, which is applied in the field of brake shoe body preparation materials and preparation, can solve the problems that foreign products cannot be widely used, quality control cannot be carried out, and the price is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

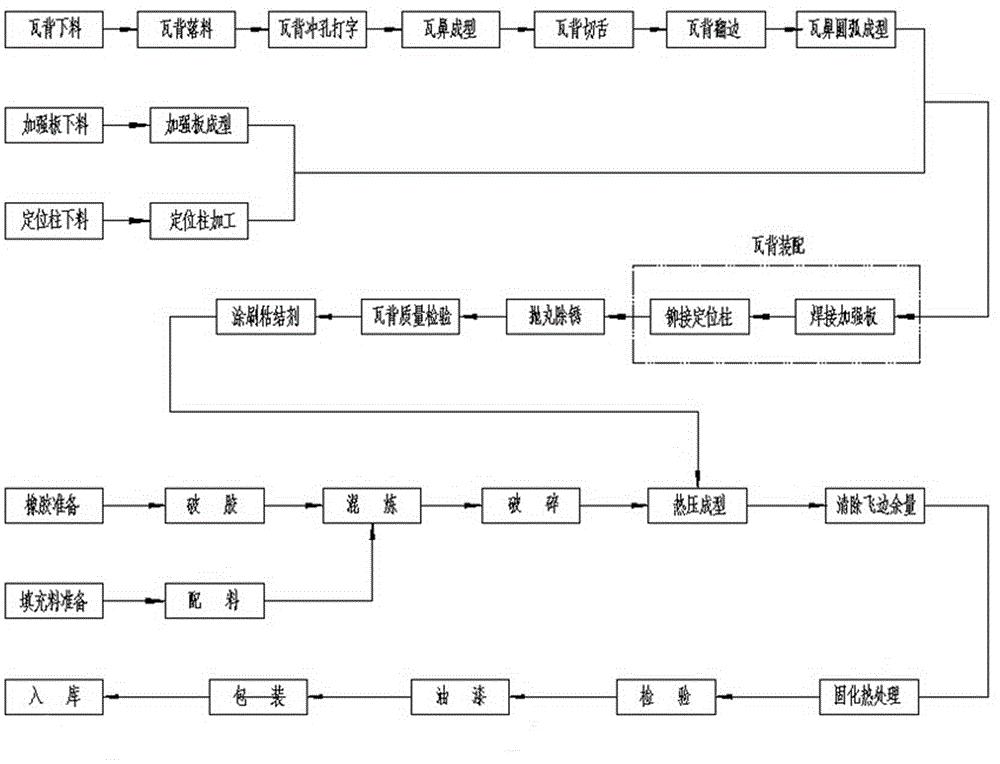

Method used

Image

Examples

Embodiment 1

[0031] A brake shoe body preparation material for a synthetic brake shoe of a high-power railway locomotive, which is composed of components in the following weight ratio: 10g per part

[0032] 9 parts of nitrile rubber, 5 parts of phenolic resin, 8.5 parts of sepiolite, 21 parts of iron powder, 3.5 parts of steel wool fiber, 0.4 part of bauxite, 12 parts of composite fiber, 16.5 parts of barium sulfate, 14 parts of graphite, potassium long 5.5 parts of stone, 0.5 parts of accelerator, 0.4 parts of zinc oxide, 0.4 parts of stearic acid, and 0.8 parts of sulfur.

[0033] The preparation method of the brake shoe body is as follows: Weigh the nitrile rubber of the specified weight, after the rubber is broken, add other ingredients of the specified weight in sequence: phenolic resin, sepiolite, iron powder, steel wool brazing fiber, bauxite, compound Fiber, barium sulfate, graphite, potassium feldspar, accelerator, zinc oxide, stearic acid, sulfur, then kneading, crushing, and fin...

Embodiment 2

[0037] A brake shoe body preparation material for a synthetic brake shoe of a high-power railway locomotive, which is composed of components with the following weight ratios:

[0038] 9.6 parts of nitrile rubber, 4.3 parts of phenolic resin, 9 parts of sepiolite, 22.3 parts of iron powder, 3.7 parts of steel wool fiber, 0.5 part of bauxite, 12.2 parts of composite fiber, 16 parts of barium sulfate, 14.9 parts of graphite, potassium long 5.8 parts of stone, 0.4 parts of accelerator, 0.3 parts of zinc oxide, 0.2 parts of stearic acid, and 0.8 parts of sulfur.

[0039] The preparation method of the brake shoe body is the same as that described in Example 1.

Embodiment 3

[0041] A brake shoe body preparation material for a synthetic brake shoe of a high-power railway locomotive, which is composed of components with the following weight ratios:

[0042] 9.5 parts of nitrile rubber, 4.5 parts of phenolic resin, 8 parts of sepiolite, 21.5 parts of iron powder, 4 parts of steel wool fiber, 0.8 part of bauxite, 12.5 parts of composite fiber, 15 parts of barium sulfate, 14.5 parts of graphite, potassium long 6 parts of stone, 0.7 part of accelerator, 0.1 part of zinc oxide, 0.3 part of stearic acid, and 0.9 part of sulfur.

[0043] The preparation method of the brake shoe body is the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com