Blast furnace smoke recycling device

A flue gas recovery and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of increasing project investment, large layout space, etc., and achieve the effect of reducing project investment and floor space, and achieving good dehydration and water sealing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the blast furnace flue gas recovery and utilization device of the present invention will be described in detail in conjunction with exemplary embodiments.

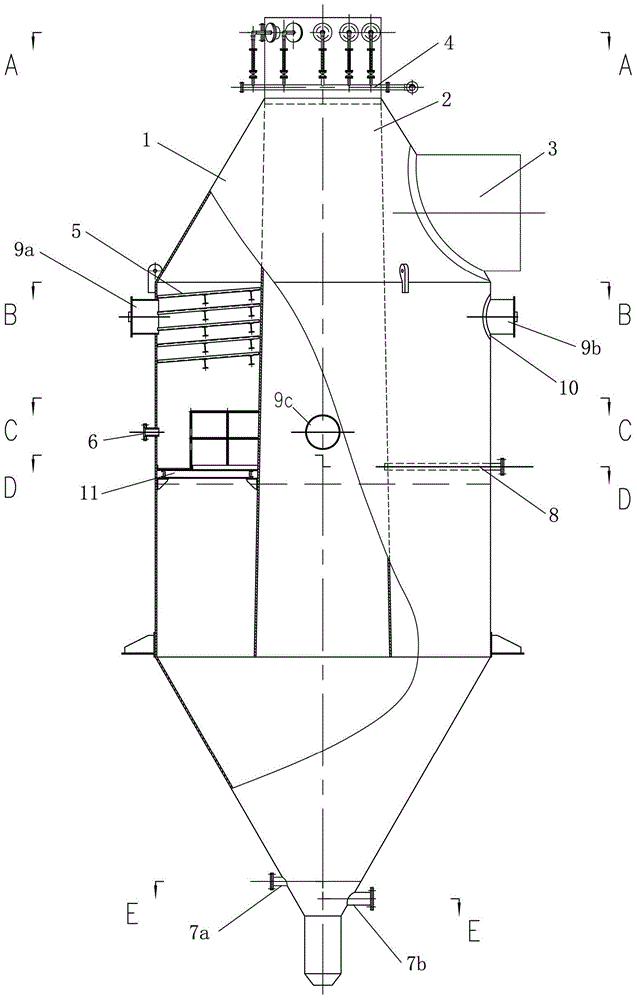

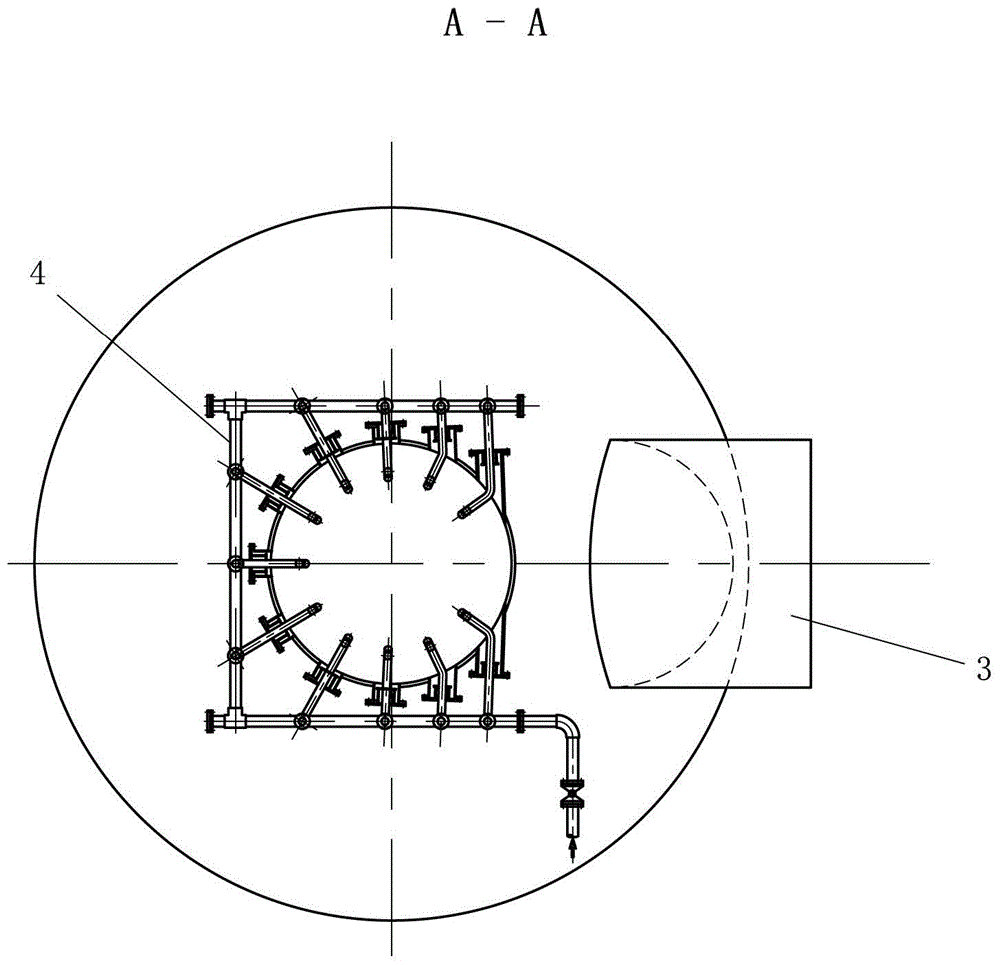

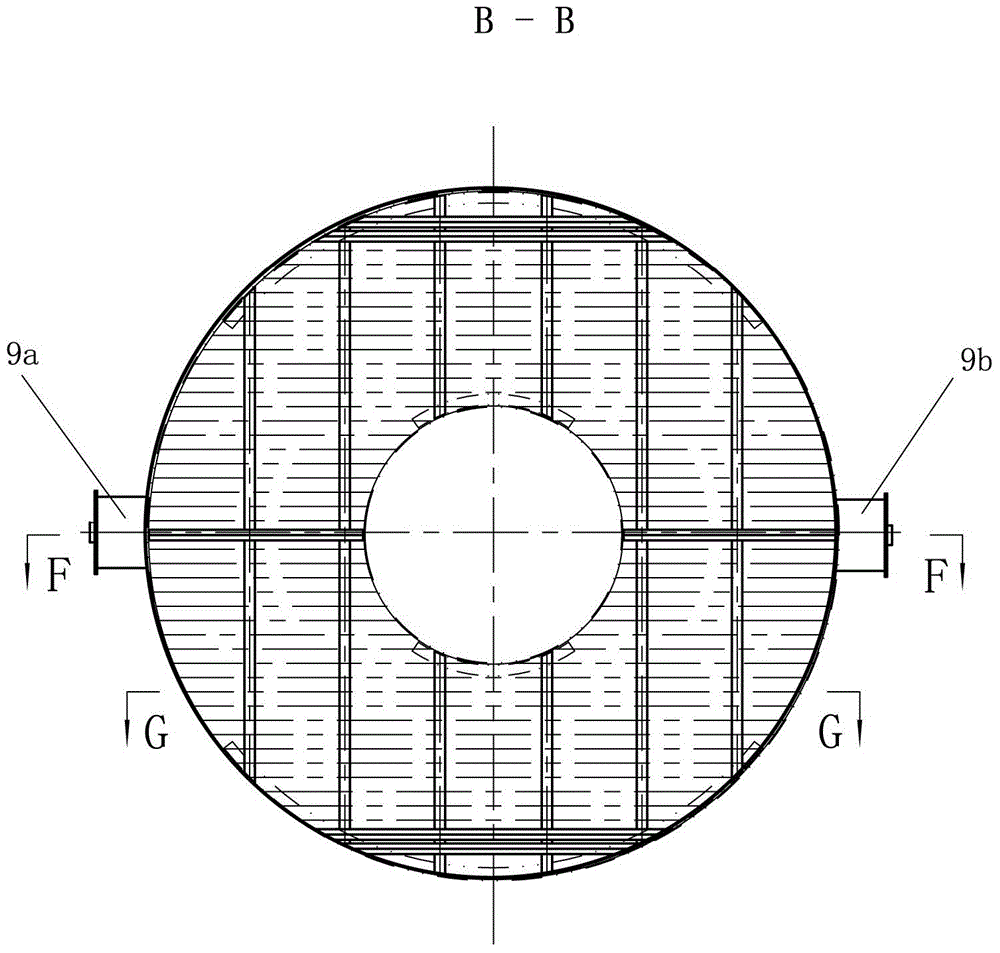

[0016] The blast furnace flue gas recovery and utilization device according to the present invention includes: a tower body, a horn tube, an air outlet pipe, a spray component, a dehydration component and a water injection pipe, wherein the tower body is surrounded by the tower wall and has a closed cavity; the horn tube is arranged In the inner cavity of the tower, the small end of the horn tube protrudes from the top of the tower body, a predetermined space is left between the large end of the horn tube and the bottom of the tower body, and the spray member is arranged above the horn tube to direct the small end from the horn tube. The blast furnace flue gas entering at the end is sprayed with cooling water; the dehydration component is arranged between the outer surface of the horn tube and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com