Method for detecting vertical bearing capacity of pile foundation

A detection method and bearing capacity technology, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of low safety and reliability, high detection cost, large static load counterweight, etc., and achieve high detection accuracy and detection Low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

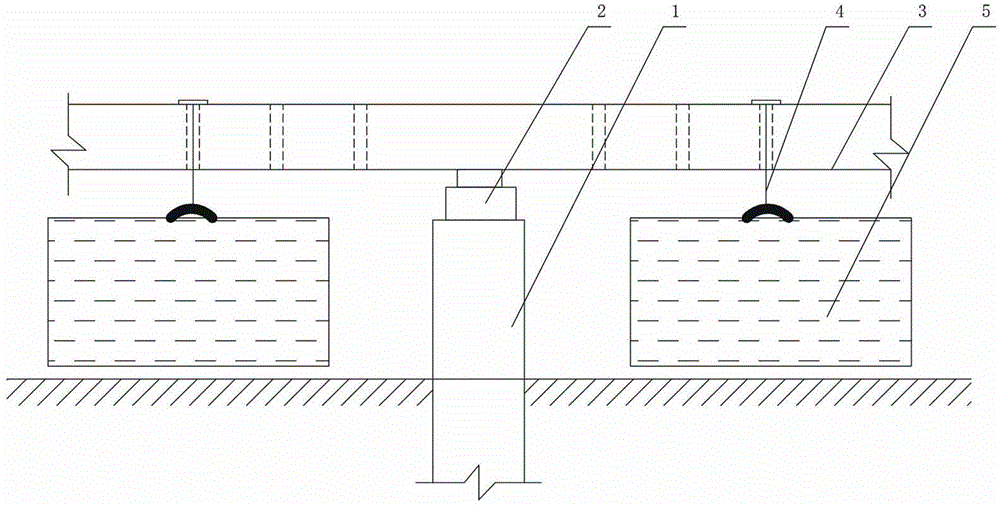

[0034] Embodiment 1: as figure 1 As shown, when the present invention carries out the vertical static load detection in the vertical bearing capacity of the pile foundation, the steps are as follows:

[0035] (1) On the top of the pile foundation 1 to be inspected, install a test piece 2 for testing the bearing capacity. The test piece 2 can use a jack or a load box according to actual needs, as long as the bearing capacity test can be completed.

[0036] (2) Install a detection girder 3 with a certain rigidity and strength on the top of the detection part 2. The detection girder 3 is directly arranged above the jack or the load box 2, and its length and diameter are configured according to actual needs to meet the actual load. The need for detection shall prevail.

[0037] (3) More than one hoisting part 4 is arranged on the girder 3 for testing, and the reusable medium container 5 is hoisted through the hoisting part 4. The medium can be water or sand or other taken media a...

Embodiment 2

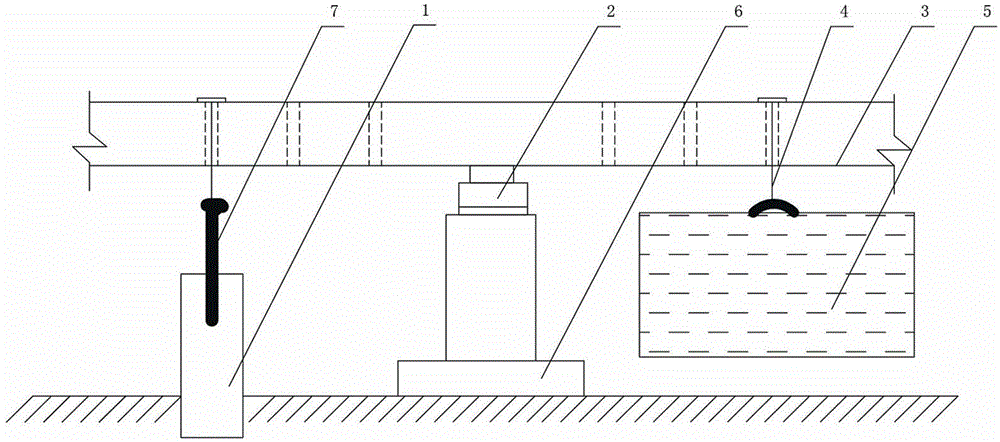

[0041] Embodiment 2: as figure 2 As shown, when the present invention detects the uplift resistance of the pile foundation in the vertical bearing capacity of the pile foundation (taking a pile foundation on land as an example), the steps are as follows:

[0042] (1) Set a support assembly 6 on one side of the pile foundation 1 to be inspected. The support assembly 6 can be a cast-in-place reinforced concrete pier or slab, and the detection part 2 is fixedly installed on the support assembly 6, and it is used as a girder for inspection 3 load-bearing foundation. In actual operation, after the support assembly 6 reaches the design strength, a jack or a load box can be installed at the center of its top, and then the girder 3 for detection can be placed on the top of the jack or load box, so that the two ends or one end of the girder 3 for detection are located at It is to be detected directly above pile 1.

[0043](2) Arrange a hoisting part 4 at both ends of the girder 3 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com