Drilling pressure relief type drilling tool jamming accident fishing tool and method

A salvage tool and accident technology, which are applied in the field of salvage tools for near-horizontal borehole sticking accidents and accident drilling tool salvage, can solve problems such as low salvage efficiency, salvage drilling tool stuck accidents, and narrow application range, and achieve salvage drilling. High efficiency, low salvage cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

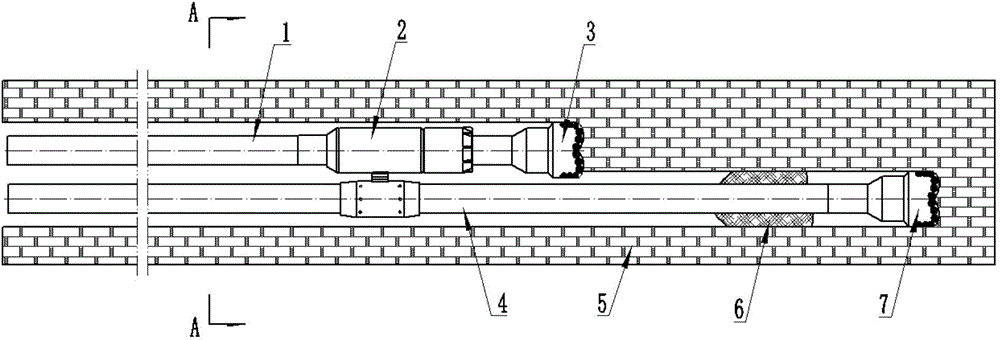

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

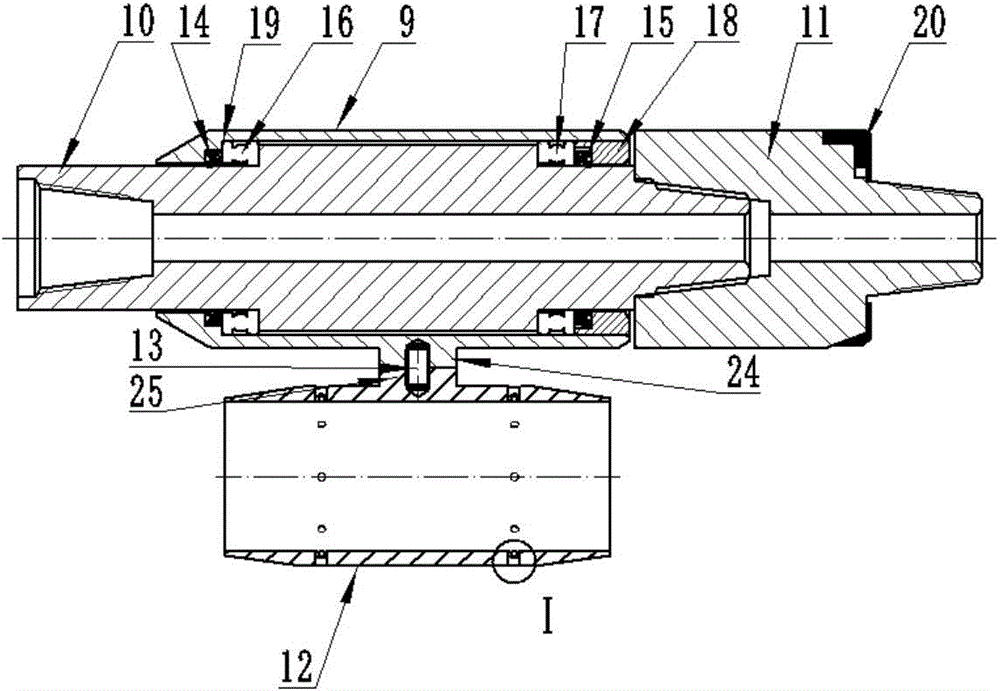

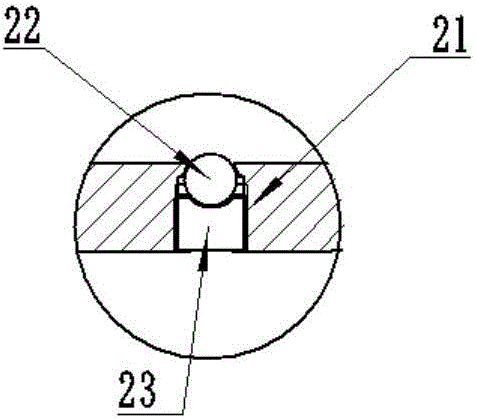

[0032] figure 1 , 2 One embodiment of the fishing tool for drill hole pressure relief type sticking accident of the present invention is described, the fishing tool 2 includes a cylindrical shell 9, and a transmission shaft 10 passing through the shell 9 is arranged inside the shell 9, Wherein, the middle part of the transmission shaft 10 is provided with a raised portion located in the casing 9, and one end of the casing 9 extends inwardly with a shoulder 19, between the shoulder 19 and the raised portion of the transmission shaft 10 There is a first seal 14 and a first bearing 16 between them, so as to prevent the transmission shaft 10 from coming out of one end of the housing 9, and the other end of the housing 9 is provided with an end cover 18, and the end cover 18 is preferably passed through The thread is connected with the housing 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com