Method for measuring contents of octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene ether in paper

A technology of octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene ether is applied in the field of physical and chemical inspection of paper materials, which can solve problems such as significant NPnEO content, and achieve short detection time, simple operation and high recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

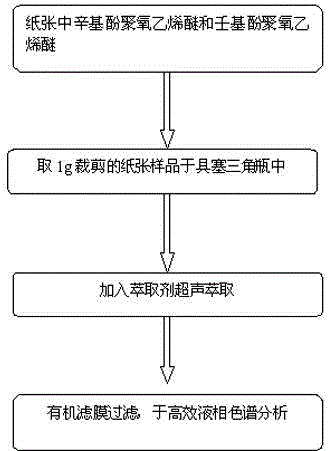

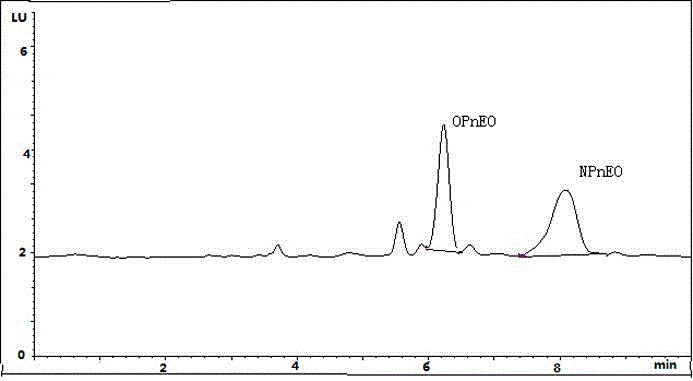

[0027] In this embodiment, the determination method for the content of octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene ether in paper is as follows (the flow chart of the detection method is as follows figure 1 shown)

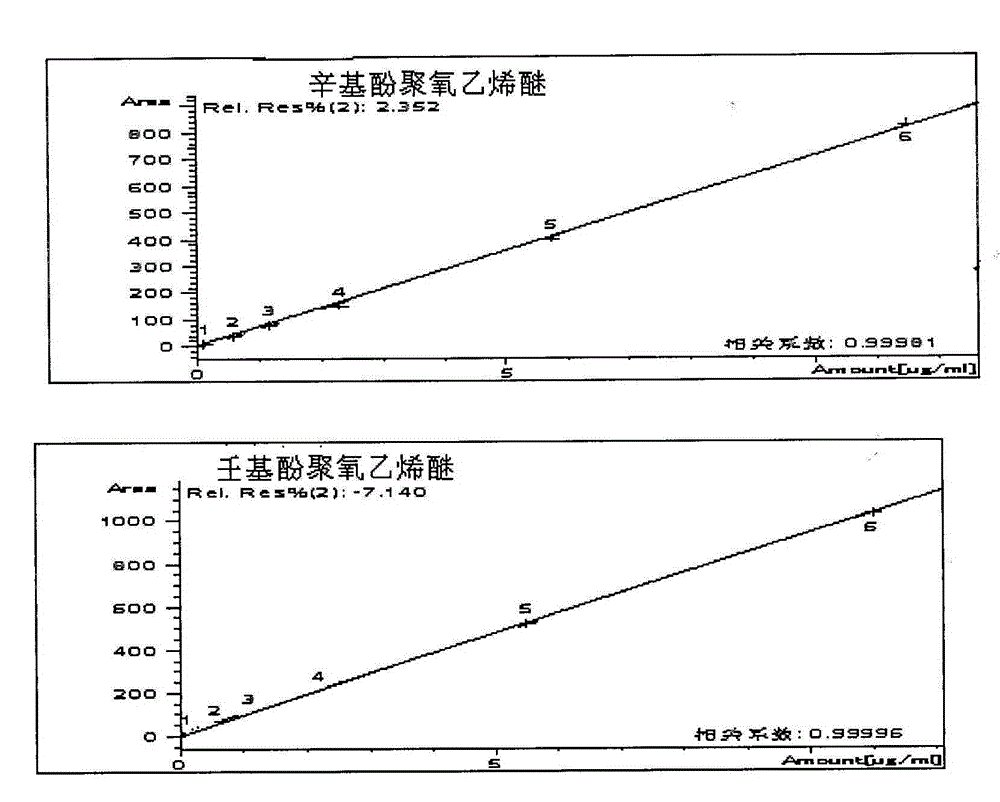

[0028](1) Preparation of standard solution: Accurately weigh 0.0100 g of octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene ether standard products, dissolve them in a 100 mL volumetric flask with methanol, and prepare a compound with a concentration of 100 mg / L. Mix standard stock solutions. Pipette 0.01mL, 0.05mL, 0.1mL, 0.25mL, 0.50mL, and 1mL of the mixed standard stock solution into a 10mL volumetric flask, dilute to volume with methanol, and prepare octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene The concentrations of the vinyl ether series standard solutions are: 0.10μg / mL, 0.50μg / mL, 1.00μg / mL, 2.50μg / mL, 5.00μg / mL and 10.00μg / mL to obtain a series of standard working solutions, which are stored at 2°C...

Embodiment 2

[0049] In this embodiment, the detection method for the repeatability and standard addition recovery of the method of the present invention is as follows.

[0050] Adopt the sample standard addition recovery rate test, add the standard solution of three different concentrations of low, medium and high respectively in the sample and carry out standard addition rate test, each sample measures 5 times respectively, the condition of chromatographic analysis is the same as embodiment 1, calculates according to analysis result The standard addition recovery of octylphenol polyoxyethylene ether and nonylphenol polyoxyethylene ether in the paper of this method and the relative standard deviation of measured value after the standard addition, the results are shown in table 2;

[0051] Table 2 Recovery and repeatability of octylphenol ethoxylates and nonylphenol ethoxylates in paper (n=5)

[0052]

[0053] As can be seen from Table 2, on the three spiked levels, the average recoverie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com