Acceleration type linear magnetic gear permanent magnet composite motor

A composite motor and permanent magnet motor technology, applied in the direction of belts/chains/gears, electromechanical devices, electrical components, etc., can solve the problems of low wave motion speed, reduced power density, low power density, etc., to achieve high power density, reduce The effect of small size and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

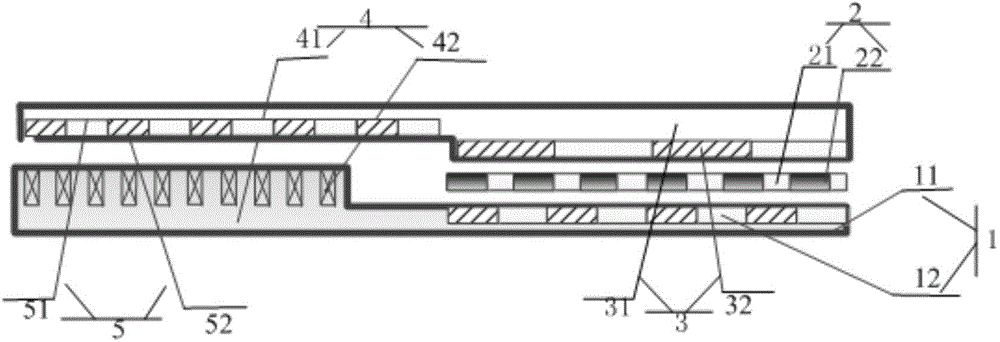

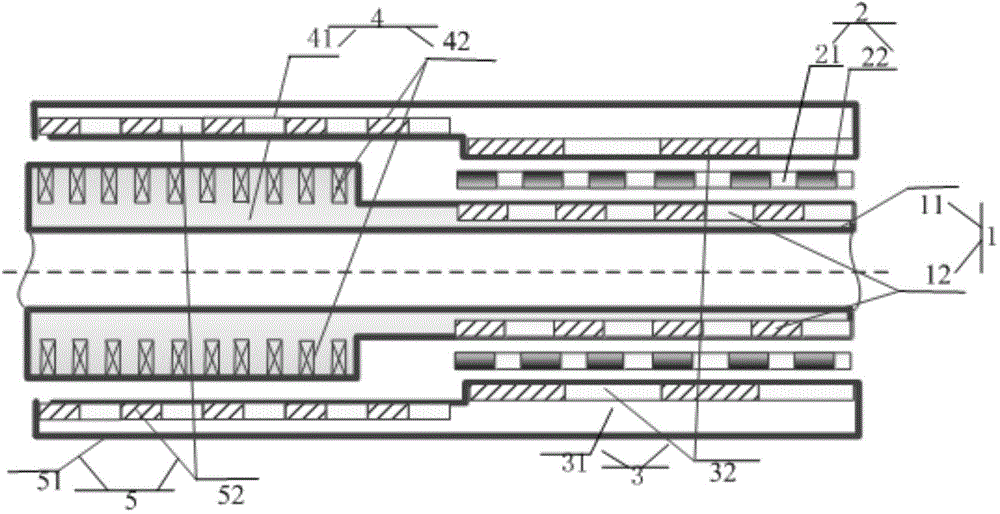

[0022] Such as figure 1 , figure 2 Shown is a speed-increasing linear magnetic gear permanent magnet composite motor, including two parts: a linear magnetic gear and a linear permanent magnet synchronous motor. The two parts are connected along the length direction and coupled in series; the two parts will be described in detail below.

[0023] The linear magnetic gear part includes a magnetic gear stator 1, a magnetic regulating sheet 2 and a magnetic gear high-speed mover 3; the magnetic gear stator 1 includes a magnetic gear stator core 11, and a magnetic gear stator is embedded in the tooth slot of the magnetic gear stator core 11 The permanent magnet 12; the magnetism regulating sheet 2 includes the magnetism regulating sheet non-magnetizer 21 and the magnetism regulating sheet magnetizer 22 arranged at staggered intervals along the length direction; the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com