Chip with micro-electromechanical structure and covering element, and method for the production of same

A technology of micro-electromechanical chips and micro-electro-mechanical structures, which is applied in the field of manufacturing chips with micro-electro-mechanical structures, especially for micro-electro-mechanical loudspeaker components, can solve the problems of complex cost and density, reduce the size of the structure, and increase the integration density , the effect of rapid manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

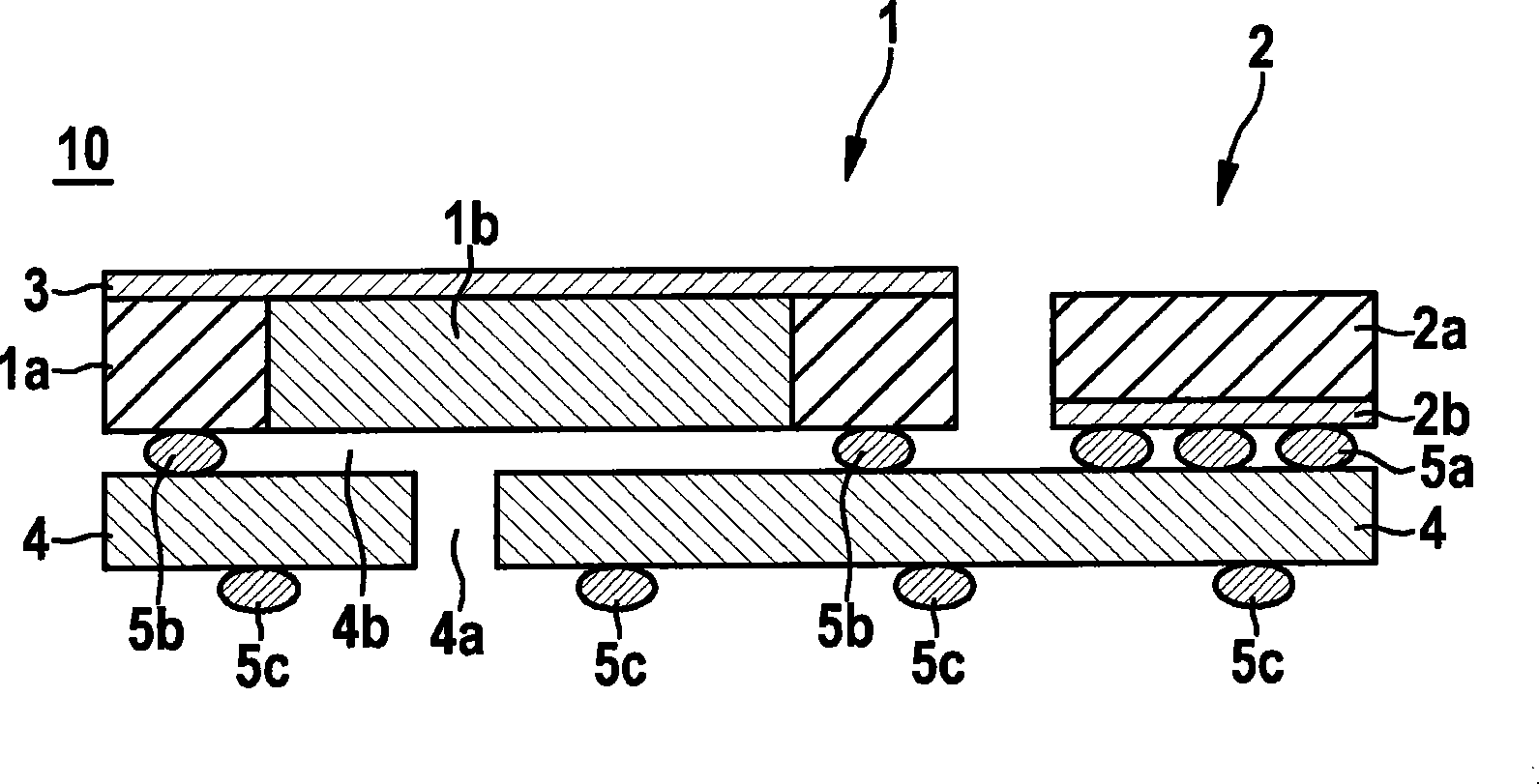

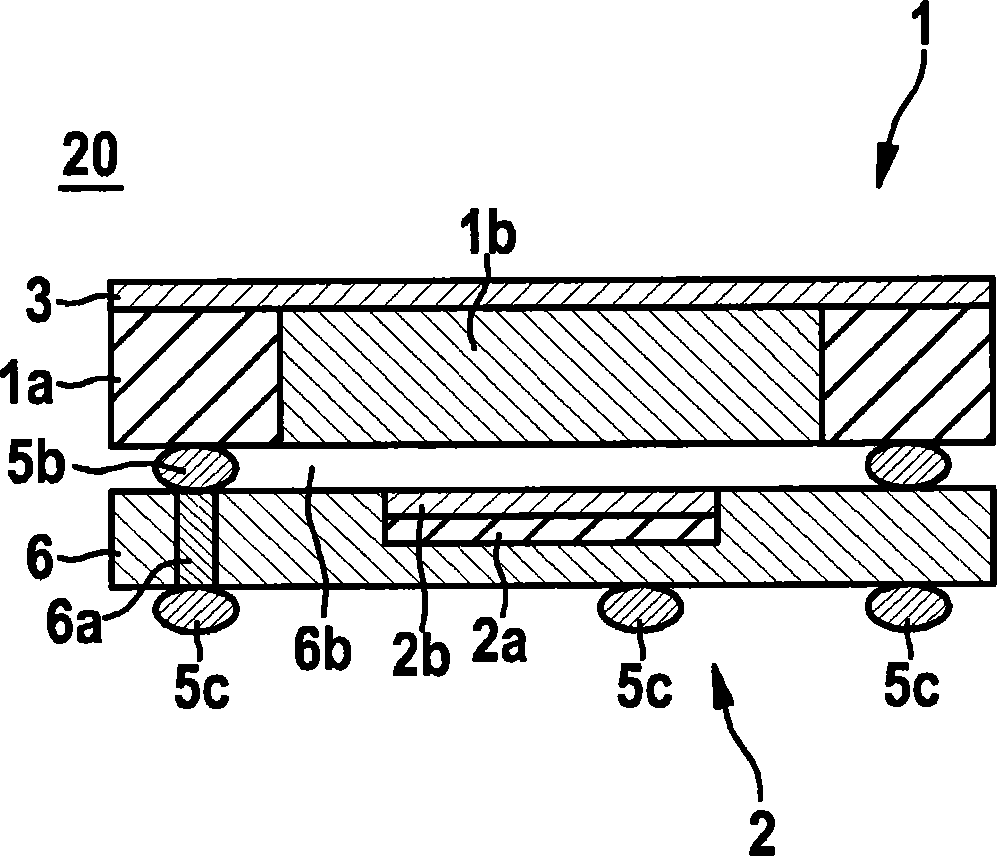

[0028] figure 1 A schematic diagram is shown of a chip package 10 with a chip 1 having a microelectromechanical structure, hereinafter referred to simply as a MEMS chip. The chip package 10 includes a MEMS chip 1 which may have, for example, a microelectromechanical loudspeaker structure 1b. The microelectromechanical loudspeaker structure 1b can be embodied in the substrate 1a here. The substrate 1a may, for example, comprise a silicon substrate. The microelectromechanical loudspeaker structure 1b may eg have an array of individual microelectromechanical loudspeaker elements. A protective element 3 can be applied on the surface of the MEMS chip 1 .

[0029] The protective element 3 can for example have a film, for example made of polyethylene terephthalate made of, metal grid, plastic grid or filter layer. The protective element 3 can, for example, be acoustically transparent, that is to say have a high permeability with respect to the propagation of sound waves. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com