Using method of high-speed steel roll on Steckel mill

A technology of high-speed steel in a steel-steel mill, which is applied in the field of high-speed steel rolls on a steel-steel mill, can solve problems such as product quality problems, and achieve the effects of good plate shape, increased service life, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

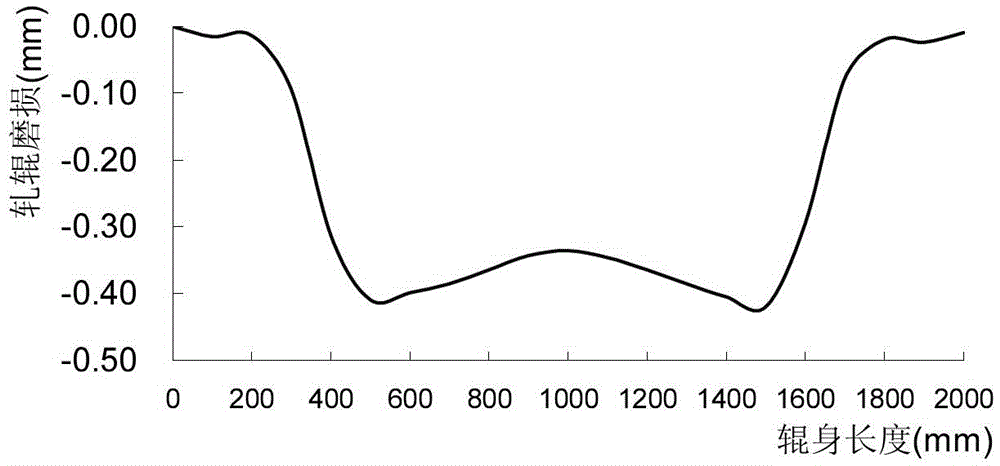

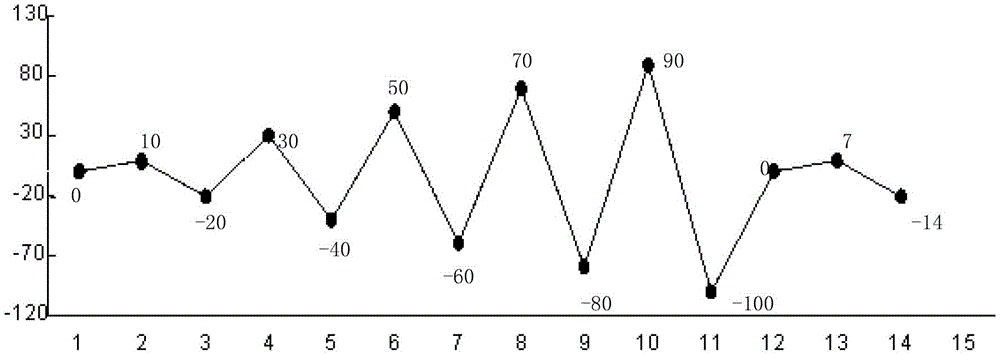

[0025] The present invention uses roll diameter to be 640~720mm, the roll body length of the high-speed steel rolling steel grade 304 (such as being stainless steel 304, the present invention can also produce steel grade to comprise 300,400 series) that is 2000mm on the steckel mill, finally The rolling temperature is controlled at 950-1030°C. Since the working environment of the steel coil mill is harsher than that of ordinary hot continuous rolling, the rolling time of the steel coil mill is long, the temperature drop of the strip is large, and the rolling load is heavy; the steel coil mill needs to reciprocate and bite the steel strip for many times, and the impact stress on the roll is large; There is a lot of scale in the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com