Fixture for laser welding machine for large-diameter thin-walled parts

A technology for laser welding machines and thin-walled parts, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., to achieve the effect of zero-gravity operation, easy and convenient clamping process, and reduce system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

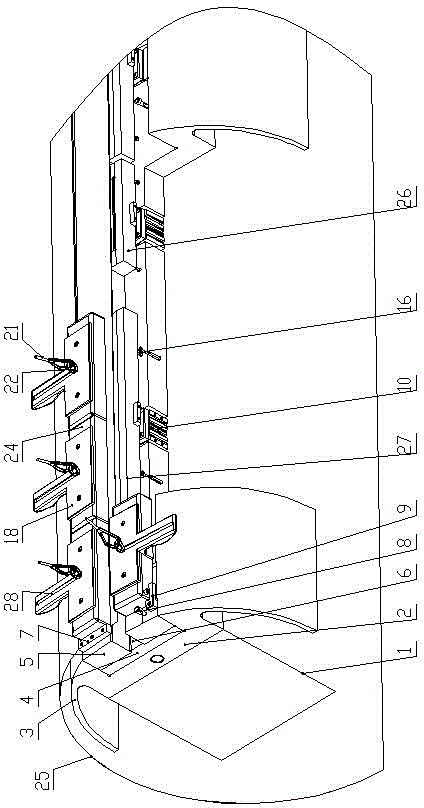

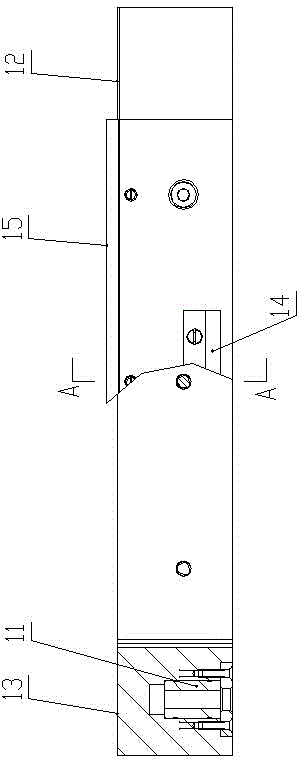

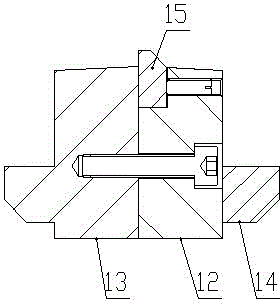

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the laser welding machine clamp for large-diameter thin-walled parts of the present invention includes a supporting positioning part, a seam mechanism and a clamping mechanism. The supporting positioning part includes a fixed frame 1 and a clamp body 2 arranged on the fixed frame 1. 2 The left and right sides of both ends are provided with an arc-shaped plate 3 for supporting large-diameter thin-walled parts. The top of the clamp body 2 is provided with a mounting groove along the length direction, and a backing plate 4 is provided at the bottom of the installation groove. There are two pad irons 5. The upper surface of the pad iron 5 is a slope with a high inner surface and a lower outer surface. The angle between the upper surface of the pad iron 5 and the horizontal plane is 3°. A ventilation groove 6 is formed between the two pad irons 5. The two pad irons The same end of the iron 5 is respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com